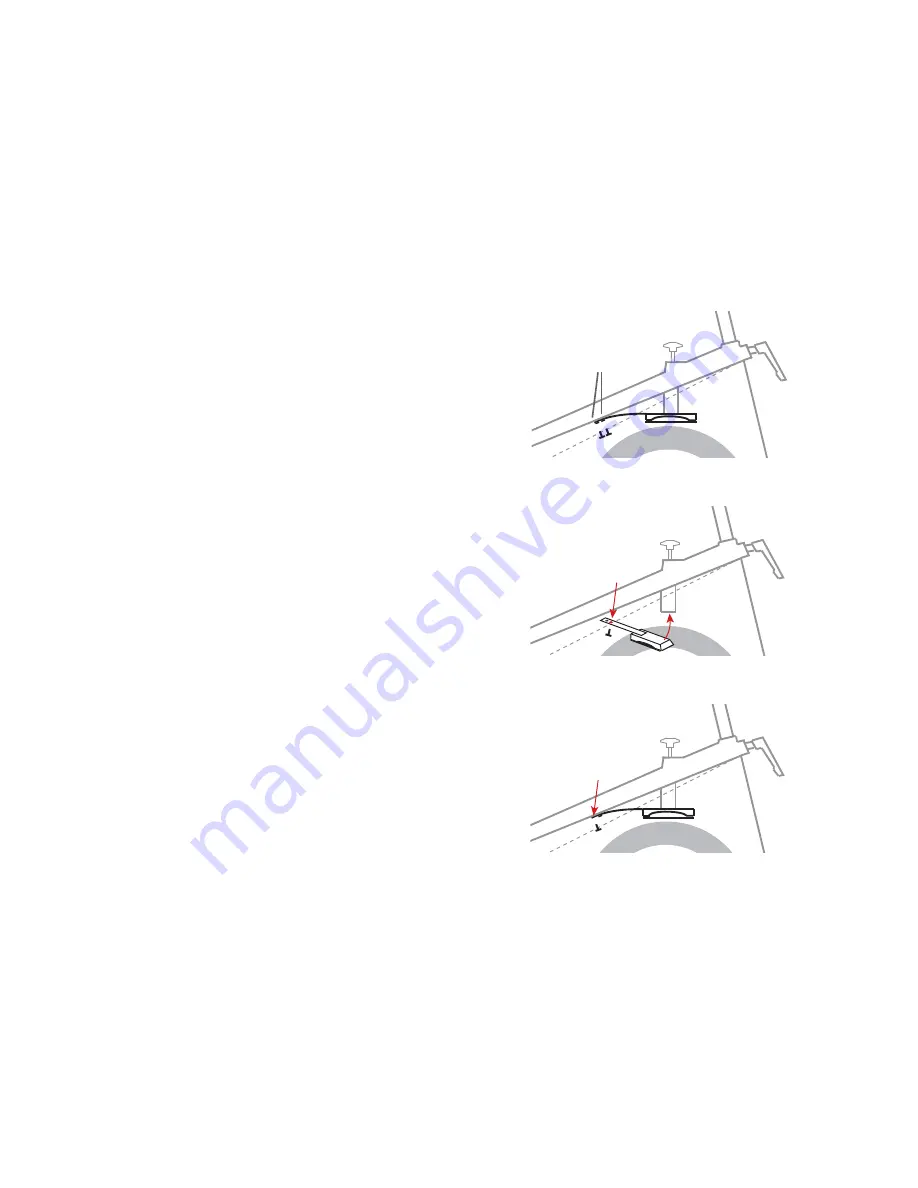

3: Release tension completely on the brake.

4: Remove the two screws holding the

brake block to the frame by using an 8 mm

wrench, see fi gure 13.

5: Take the new brake block and fasten it to

the frame by tightening the screw closest

to the brake block. Then place the block in

the correct position under the brake, see

fi gure 14.

6: Fasten the remaining screw furthest

away from the block, and then make sure

that both screws are tightened properly,

see fi gure 15.

7: Grease should be applied to the cavity on

top of the brake block or to the top nut on

the brake to ensure a smooth interaction

between the two.

8: Finally, remount the side cover by

screwing in the corner screws fi rst.

Hereafter the remaining screws.

Figure 14

REMOVE

Figure 13

Figure 15