LUBRICATION OF THE

BRAKE

The cycle needs lubrication if

it makes a noise or if the brake

catches too hard. Only use the

original BODY BIKE lubrication

oil. It is important only to

cover the friction surface

of the flywheel in a thin oil

film. If the oil film is too thick

the oil will gather in front

of the brake pad and make

the cycle ride uneven. For

easy lubrication use a special

tool which can be bought

at BODY BIKE International

A/S. Alternatively, wrap an

oily cloth around your index

finger.

CLEANING THE POSTS

Every other week the posts

need cleaning to protect them

from sweat etc.

1: Pull out the seat post and

the front post and wipe them

clean with an oily cloth, see

figure 12.

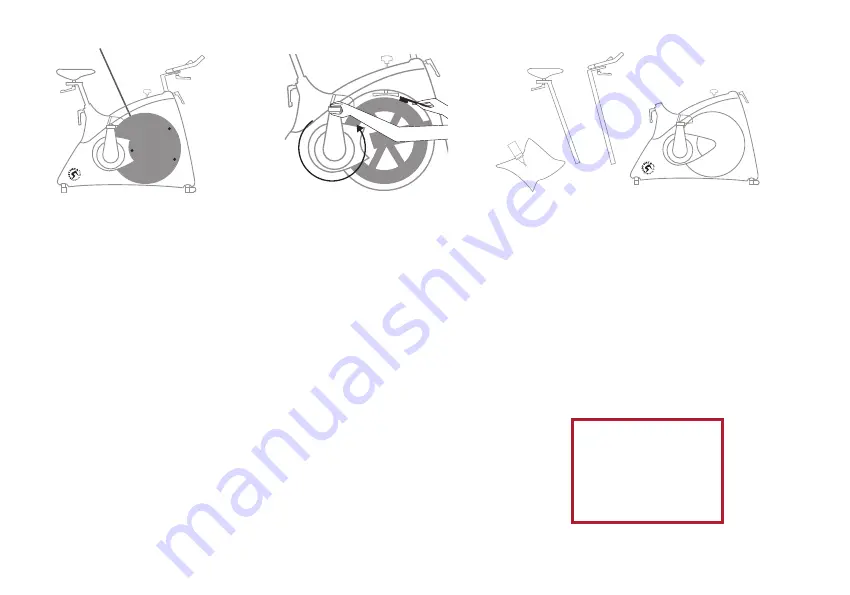

Figure 10

Figure 11

Figure 12

SERVICE HATCH

Please note:

The posts should be

cleaned every other

week to keep them

in good condition

1: Remove the service hatch by

loosening the three locks with a

coin, see figure 10.

2: Wet the special sponge tool with

oil and press the extra oil out of the

sponge.

3: Place it on top of the flywheel

while turning the pedals counter

clockwise with the other hand, see

figure 11.

4: For control of correct lubrication

put your index finger on the

flywheel while turning the pedal to

make sure a thin oil film is covering

the entire friction surface of the

flywheel.