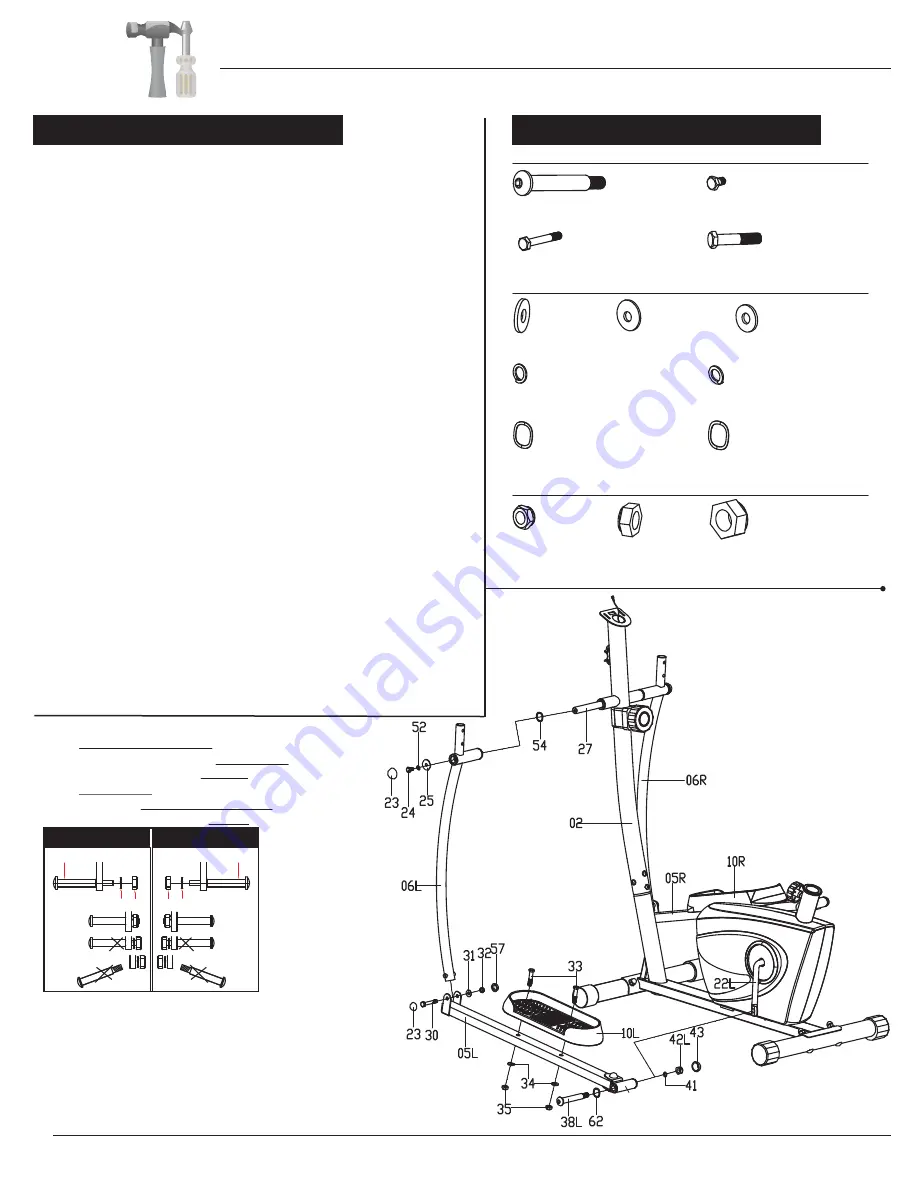

Assembly Instructions

Hardware Required

Bolts

Washers

Nuts

[1 Piece of each]

Hardware Required

Please refer to the diagram below and pay special attention to corresponding

left & right side parts. Misplacing parts during assembly will lead to incorrect

assembly and may result in serious injury.

#38L/R. Left/Right Pedal Hinge Bolt

[1 Piece of each]

#30. Hex Bolt

(M8×55 mm)

[2 Pieces]

#33. Hex Bolt

(M10×45 mm)

[4 Pieces]

#24. Hex Bolt (M8×15 mm)

[2 Pieces]

#41. Spring Washer (Φ13×B2)

[2 Pieces]

#31. Washer

(M8,t1.5)

[2 Pieces]

#34. Washer (M10)

[4 Pieces]

#25. Washer

(M8, t2.0)

[2 Pieces]

#52. Spring Washer (M8)

[2 Pieces]

#62. Special Washer

(D17×0.3)

[2 Pieces]

#54. Special Washer

(Φ20)

[2 Pieces]

#32. Nylon Nut

(M8)

[2 Pieces]

#35. Nylon Nut

(M10)

[4 Pieces]

#42L. Left Nylon Nut

#42R. Right Nylon Nut

Pedal Hinge Bolt (#38L)

and CLOCKWISE to tighten

Left Nylon Nut (#42L)

with

BLACK

inner nylon ring.

A s s e m b l y S t e p 3

A s s e m b l y S t e p 3

LEFT SIDE

RIGHT SIDE

38L

38R

41 42L 42R41

40L

Note:

Keep the

Left/Right Pedal Hinge Bolt

(#38L/38R)

perfectly

straight as they go

through the

Left/Right Pedal Connection

Joint (#40L/R)

and the

Crank (#22L/R).

If the

Left/Right Pedal Hinge Bolt (#38L/38R)

are connected to the

Crank (#22L/22R)

incorrectly,

damage to the

Left/Right Pedal Hinge Bolt

(#38L/38R)

and

Crank (#22L/22R)

will occur.

PLEASE NOTE:

b):Turn CLOCKWISE to tighten the

Right Pedal Hinge

Bolt (#38R)

and COUNTERCLOCKWISE to tighten

Right Nylon Nut (#42R)

with

WHITE

inner nylon ring.

Remove two

Hex Bolts (#24)

, two

Spring Washers (#52)

, two

Washers (#25)

and two

Special Washers (#54)

that are

pre-assembled on the

Front Post Axle (#27)

and set them aside

as they will be used in a later process.

Insert the

Front Post Axle (#27)

through the

Front Post (#02).

Make sure the

Front Post Axle (#27)

is centered. If you encounter

too much friction, try using WD40 or Vaseline asa lubricant.

Slide one

Special Washer (#54)

onto the left side of the

Front Post

Axle (#27)

then followed by

Left Coupler Bar (#06L).

Secure them

together by hand tighten one

Hex Bolt (#24),

one

Spring Washer

(#52)

and one

Washer (#25)

that were previously removed.

Align and attach the left

Pedal Connection Joint (#40L)

on the

Left Pedal Arm (#05L)

to the left

Crank (#22L)

. Insert

Left Pedal

Hinge Bolt (#38L)

through a

Special Washer (#62)

followed by

left

Pedal Connection Joint (#40L)

and left

Crank (#22L)

. Screw

the

Left Pedal Hinge Bolt (#38L)

tightly into the left

Crank (#22L)

by turning COUNTERCLOCKWISE and then secure it by hand tighten

one

Spring

Washer

(#41)

and one

Left Nylon Nut (#42L)

by turning it

CLOCKWISE.

Align and attach the

Left Coupler Bar (#06L)

to the

Left Pedal

Arm (#05L)

. Hand Tighten them together using a

Hex Bolt (#30),

a

Washer (#31)

and a

Nylon Nut (#32).

At this point secure the

Hex Bolts (#24), Hex Bolt (#30)

and

Left

Nylon Nut (#42L)

that were hand tightened previously.

Attach

Bolt Cap (#23)

to the end of

Hex Bolt (#24)

and

Hex Bolt

(#30).

Attach

Bolt Cap (#43)

to the end of

Left Nylon Nut (#42L).

Attach

Bolt Cap (#57)

to the end of

Nylon Nut (#32).

Attach the

Left Pedal (#10L)

to the

Left Pedal Arm (#05L)

and

secure them together using two

Hex Bolts (#33),

two

Washers

(#34)

and two

Nylon Nuts (#35).

Repeat this process on the other side.

a):Turn COUNTERCLOCKWISE to tighten the

Left

Page 7

BRM2170/2180