3

SADDLE-TAPPING VALVE INSTALLATION ON COPPER TUBE

CAUTION:

This saddle-tapping valve is not designed for installation on flex line tubing.

NOTE:

State, provincial and local plumbing codes may prohibit use of saddle-tapping valves.

1.

CAUTION:

If no shut off valve is installed under

sink, close main water valve during this Installation.

Locate shut off valves on water lines under sink. To

identify hot supply pipe and cold supply pipe, turn

both faucets on and let water run. As water flows, the

hot water pipe becomes noticeably warmer.

2.

CAUTION:

Do not install feed water assembly on the

hot water line.

Turn off cold water supply by closing shut off valve.

Drain the water line by opening sink faucet. Some

mixing-type faucets may require hot water supply be

shut off as well.

NOTE:

All instructions refer to components shown in

Figure 3 unless otherwise noted.

3.

CAUTION:

Do not turn valve handle before or while

installing saddle-tapping valve. Make sure piercing

lance does not protrude beyond rubber gasket before

installing valve.

Assemble saddle-tapping valve assembly on tube.

a. Hold back plate against tube.

•

3/8" copper tubing use back plate smaller

radius.

•

1/2" copper tubing, use back plate larger

radius

b. Hold valve saddle against tubing in a position

directly opposite back plate.

c. Tighten screw enough so valve saddle and back

plate are held securely against tube.

d. Rotate assembly so tubing connection is aligned

toward RO Module feed port.

e. Tighten screw firmly. Do not crush tube.

4. Connect source water feed tubing to valve body

using compression fitting.

a. Slide nut and sleeve onto tubing (in that order).

b. Install insert into plastic tubing.

c. Install tube with insert and sleeve into valve body.

d. Thread compression nut onto valve body, tighten.

5. Turn saddle-tapping valve handle clockwise until it is

firmly seated and piercing lance is fully extended.

6.

CAUTION:

Supply line is pierced and valve is closed.

Do not open valve until system is activated (See

Activating the System, page 9).

Turn on cold water supply. Check saddle-tapping

valve installation for leaks. Allow water to run from

faucet for a few minutes to clear any debris in the line

caused by installation.

NOTE:

If flow from sink faucet is reduced, clean

faucet aerator.

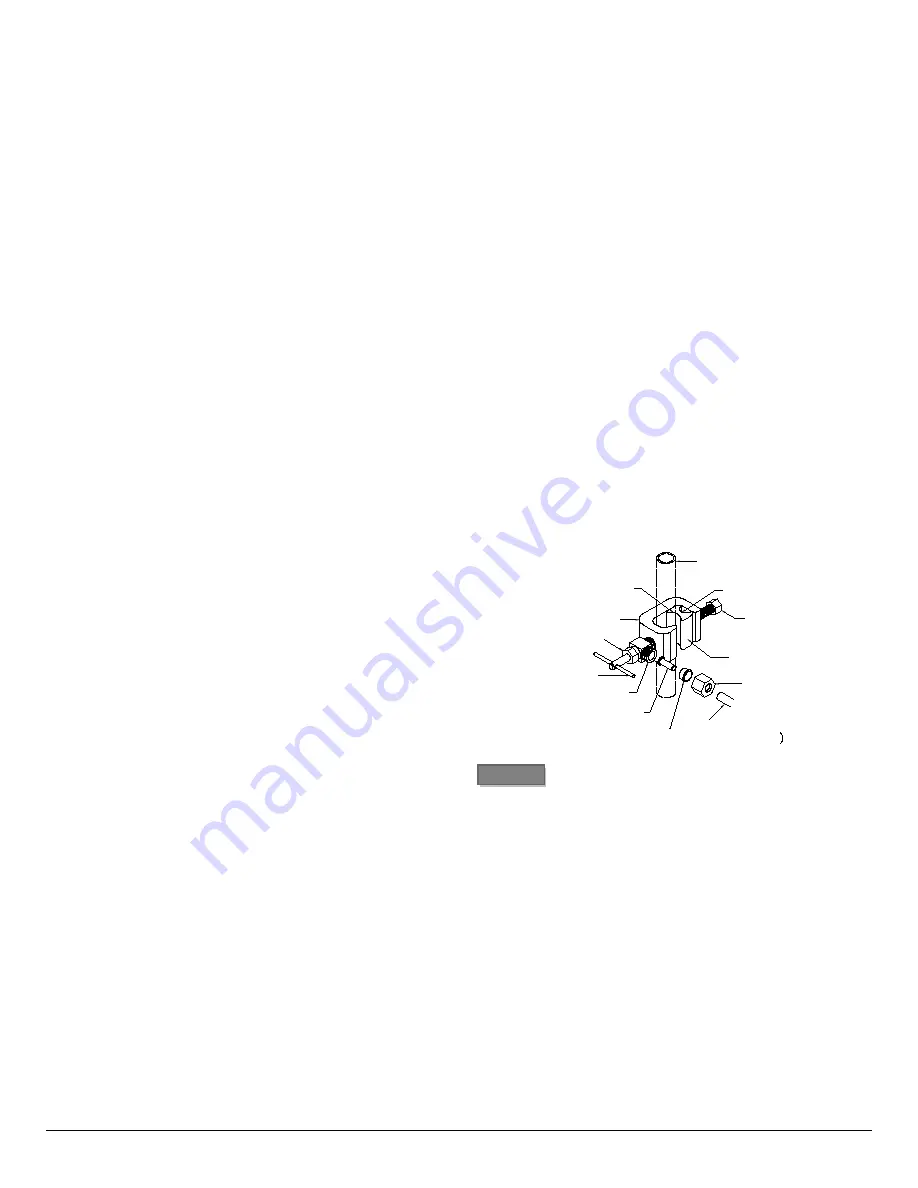

EXISTING 1/2"

COPPER TUBING

HOUSEHOLD

COLD WATER LINE

REVERSIBLE

BACK PLATE

COMPRESSION

NUT

TUBING TO MODULE

(1/4" WHITE TUBING

SLEEVE

INSERT

VALVE HANDLE

TIGHTENING

SCREW

STEM SEAL NUT

VALVE SADDLE

SMALLER RADIUS

LARGER RADIUS

VALVE BODY

Figure 3:

Saddle-Tapping Valve Assembly

P/N 92276 installed on

1/2” Copper Tubing

7. Trim ¼” white tube to desired length. Install ¼” white

tube into ¼” white collet as shown in Figure 1.A (page

111).

ADDITIONAL POINT OF USE CONNECTION

NOTE:

Icemakers typically use 1/4" tubing as feed line. Use a reducing union for this connection.

NOTE:

Reduce the 3/8” line to 1/4” as close as possible to the additional point-of use device to minimize flow loss.

1. To connect an additional point of use (icemaker, extra

faucet in wet bar and/or another use for treated water),

place a "tee" connector in 3/8" blue line between

faucet and RO Module.

2. Connect "tee" to point-of-use with 3/8" blue tubing.

Connect tubing to point-of-use.

Connector requirements are based on type of

delivery device i.e., a typical icemaker uses

3/8" x 1/4" reducing union.