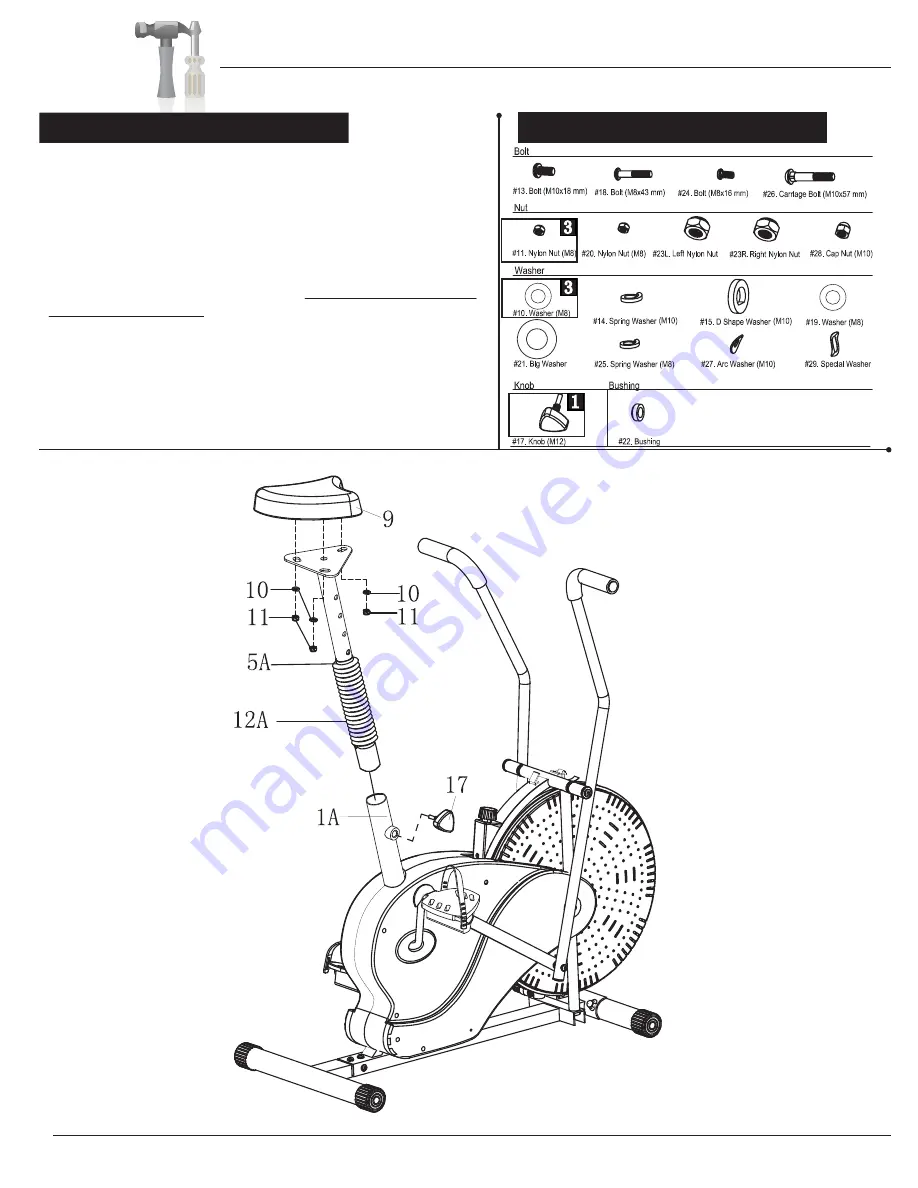

Assembly Instructions

A s s e m b l y S t e p 5

Hardware Required

55

40

1

2

3

4

55

40

1

2

3

4

BRF 700/701

Remove the three Washers (#10) and three Nuts (#11) that

are pre-assembled on the Seat (#9). Then, attach the Seat (#9)

to the Seat Tube (#5A) and secure it with three Washers (#10)

and three Nuts (#11) that were previously removed.

Attach Bellows (#12A) to the Seat Tube (#5A) as shown in

illustration below.

Insert the Seat Tube (#5A) into the opening of the post that is

protruding from the Main Frame (#1A) a minimum of 4 inches to

engage the lowest hole. Please ensure that the hole on the Seat

Tube (#5A) is facing the same side as the hole located on the

Main Frame (#1A) and insert the Knob (#17) through the Main

Frame (#1A) post and through the hole on the Seat Tube (#5A).

Please refer to the illustration below. Always ensure that the

Knob (#17) is securely tightened and engaged through the hole on

the Main Frame (#1A) and the hole setting most comfortable to you

on the Seat Tube (#5A) for your safety.

Page 11