Hardware Pack Check List

11

-5-

Assembly Pack Check List

Step2

Step3

Step1

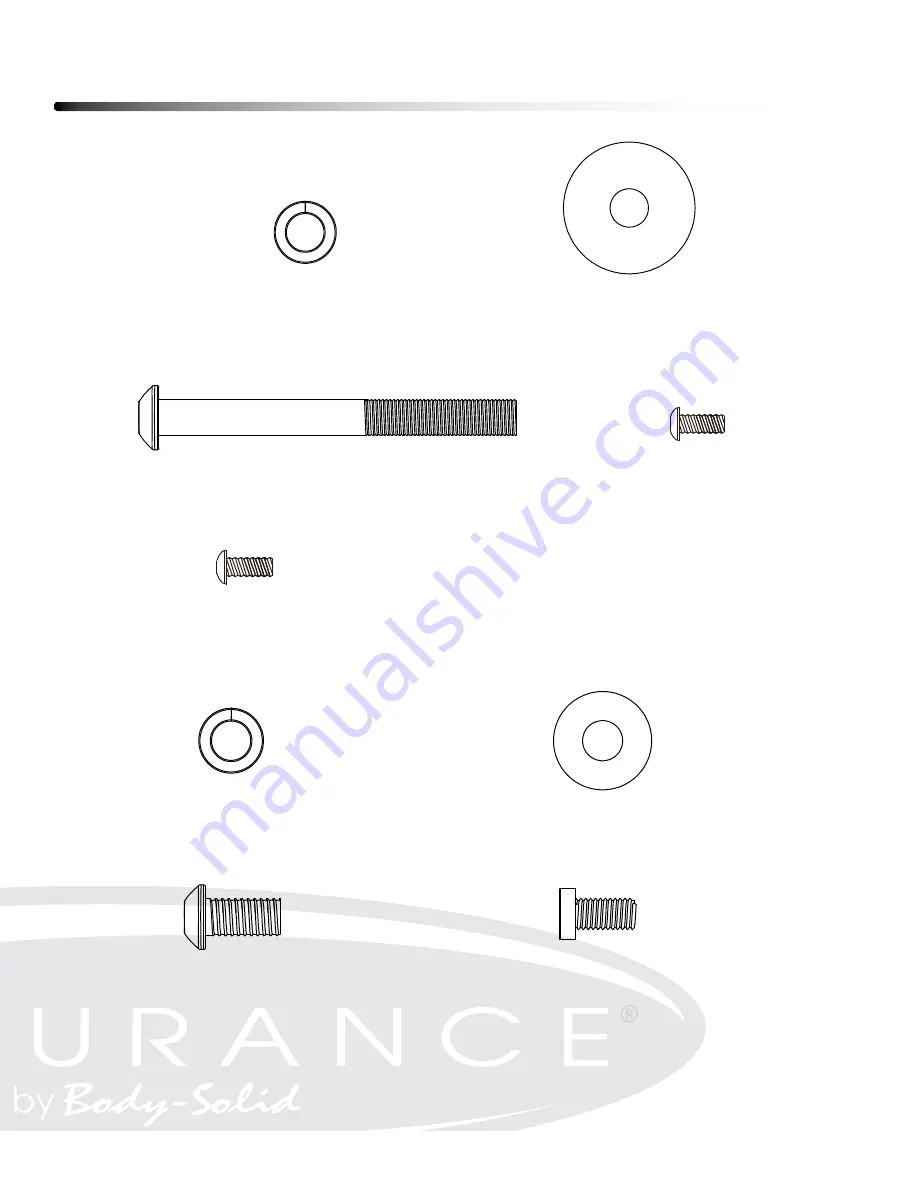

#117 - 3/8" x16.5 x2.0T x4H

Split Washer (6 pcs)

#144 - 3/8”-16 x 3”

Button Head Socket Bolt (6 pcs)

#134 - M5 x 12mm

Phillips Head Screw (4 pcs)

#116 -

ψ

3/8" x 35 x 2T

Flat Washer (6 pcs)

#134 - M5 x 12mm

Phillips Head Screw (4 pcs)

#117 - 3/8" x16.5 x2.0T x4H

Split Washer (6 pcs)

#125 -

ψ

3/8" x25 x2T

Flat Washer (6 pcs)

#145 – 3/8”-16 x3/4”

Button Head Socket Bolt (6 pcs)

#146 – M8 x1.25x12mm

Socket Head Cap Bolt (6 pcs)