10

Be careful to assemble all components

in the sequence they are presented.

28

S T E P

Note:

Leave all pulley bolts hand tight until step 15 is completed.

A.

Begin at the high pulley station. Route the metal ball end of the High Pulley Cable (85) up and

through the opening where Pulley (A1) will be installed. Route the metal ball end under the

Bi-Angular Bars (J) and then down through the next opening where Pulley (A2) will be installed.

B.

Install Pulley (A1) under Cable (85) and into Top Frame (E) as shown using:

One 52 (3/8” x 2 3/4” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

C.

Install Pulley (A2) under Cable (85) and into Top Frame (E) as shown using:

One 52 (3/8” x 2 3/4” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

D.

Route Cable (85) over the top and around pre-installed Pulley (A3) as shown.

Route Cable (85) around Pulley (A4) and install Pulley (A4) into Angled Support Frame (D) using:

One 52 (3/8” x 2 3/4” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

E.

Route Cable (85) between Pulley (A3) and pre-installed Pulley (A5).

Route Cable (85) around Pulley (A5) and back through Angled Support Frame (D).

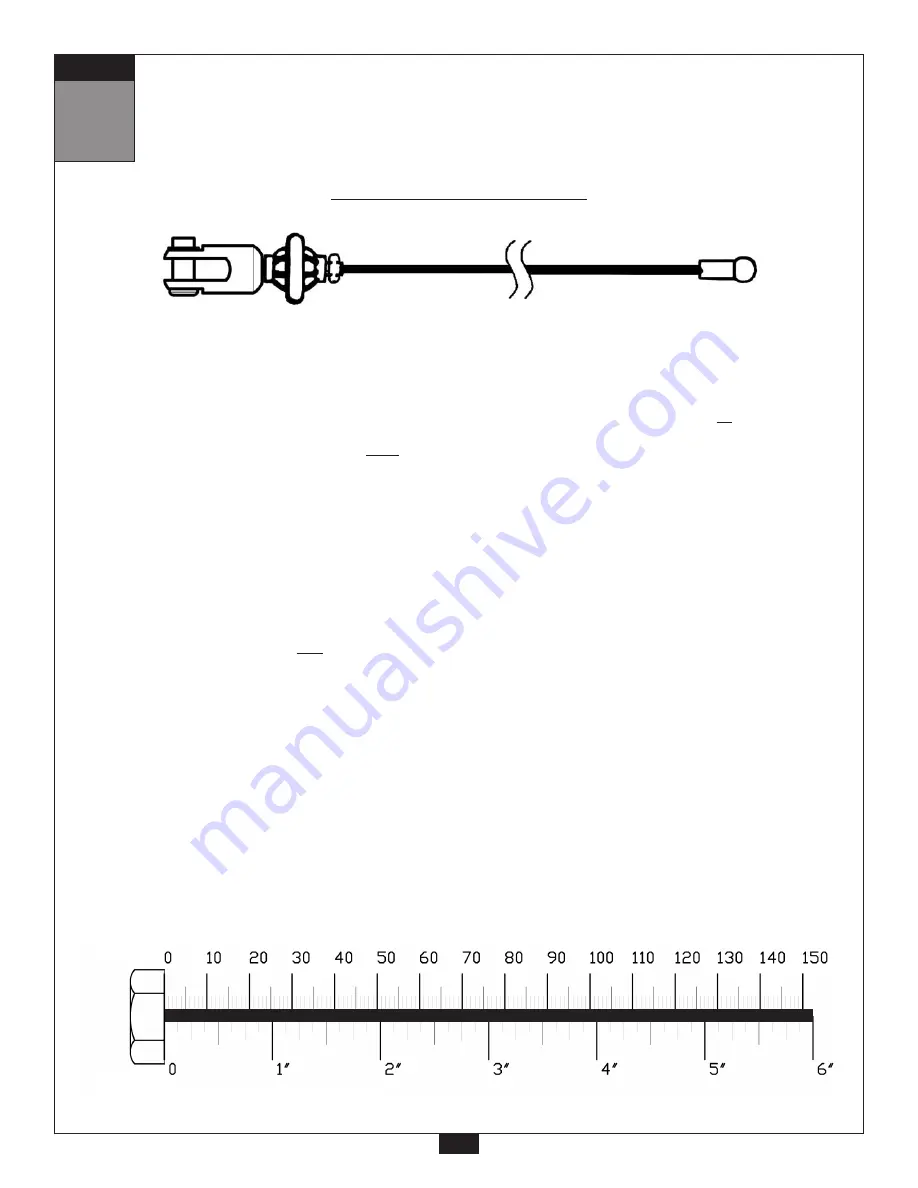

High Pulley Cable (85)

Ball Stop End

Metal Ball End

5110 mm

16’ 9”

mm

Inch

Summary of Contents for G6B25YR

Page 4: ...3 R e f e r e n c e D r a w i n g s G6B25YR ...

Page 12: ...1 11 S T E P ...

Page 14: ...2 13 S T E P ...

Page 16: ...3 15 S T E P ...

Page 18: ...4 17 S T E P ...

Page 20: ...5 19 S T E P ...

Page 22: ...6 21 S T E P REVERSE SIDE DRAWING ...

Page 24: ...7 23 S T E P ...

Page 26: ...8 25 S T E P ...

Page 28: ...9 27 S T E P ...