20

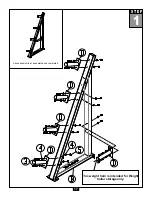

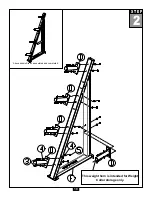

S T E P

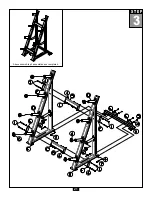

3

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Wrench tighten ALL hardware at the end of STEP 3B. Some components may be

pre-assembled.

Option #2: Weight Horn Configuration

for Bumper Plates

3A.

Attach Uprights

(B & F)

to Base Frame

(A)

using:

4 - (#2) M10x75mm Hex Head Bolt

8 - (#4) M10 Flat Washer

4 - (#5) M10 Nylon Lock Nut

3B.

Attach Two Crossmembers

(C)

to Uprights

(B & F)

using:

8 - (#1) M10x100mm Hex Head Bolt

16 - (#4) M10 Flat Washer

8 - (#5) M10 Nylon Lock Nut

3C.

Insert Rubber Donuts

(#6)

onto Weight Horns

(D)

.

Summary of Contents for GWT76

Page 1: ... A s s e m b l y I n s t r u c t i o n s O W N E R S M A N U A L V GWT76 121118 GWT76 ...

Page 8: ...45 8 G W T 7 6 Option 1 Weight Horn Configuration for Olympic Plates ...

Page 9: ...9 Option 2 Weight Horn Configuration for Bumper Plates ...

Page 11: ...S T E P 1 Above shows Step 1 assembled and completed 11 ...

Page 13: ...S T E P 2 Above shows Step 2 assembled and completed 13 ...

Page 15: ...S T E P 3 Above shows Step 3 assembled and completed 15 ...

Page 21: ...S T E P 3 Above shows Step 3 assembled and completed 21 ...

Page 22: ...45 22 N o t e s ...