T5

206

220

209

223

225

207

L3

223

T3

209

207

225

203

209

223

225

T2

209

234

223

225

202

L1

220

202

L4

223

225

209

203

T4

209

223

225

202

L2

T1

T2

T3

L2

202

203

L1

T4

L3

T5

L4

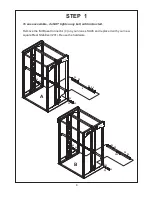

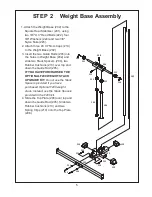

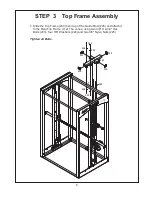

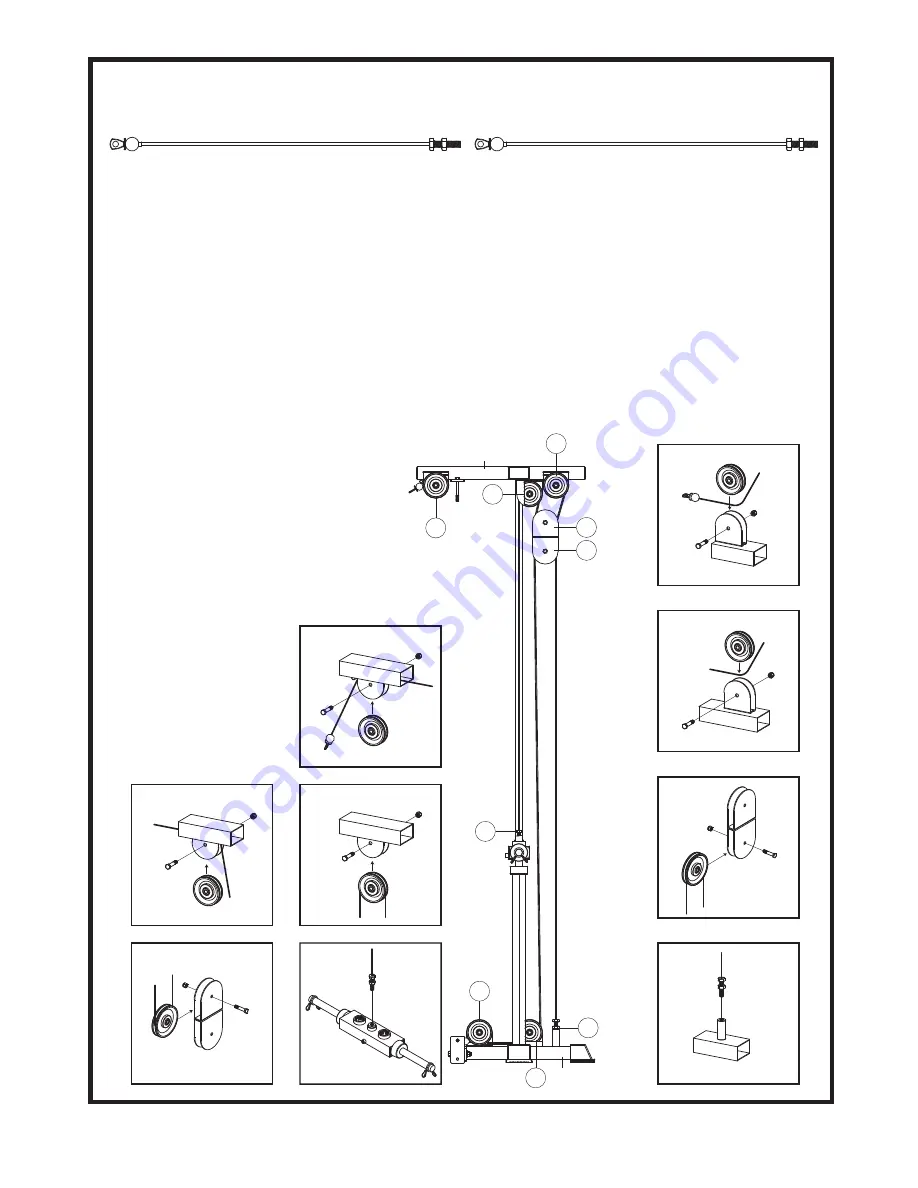

STEP 4

Top Cable & Low Cable Assembly

223

220

203

225

209

T1

7

TOP CABLE (220)

LOW CABLE (234)

Assemble cables and pulleys simultaneously

Top Cable.

1. Insert the screw end of the Top Cable (220)

into the slot in the front of the Top Frame (203).

Slide it through the inside of the Top Frame

(203), and then out of the slot in the rear.

2. Insert Pulleys into the bracket at these slots

with cable running above as shown in Figs T1

and T2. Secure the pulleys with one 3/8" X 1-

3/4" Hex Bolt (223) and one 3/8" Nylon Nut

(225) each.

3. Route the cable down and around top pulley

(T3) ( secure with one 3/8" X 1-3/4" Hex Bolt

(223) and one 3/8" Nylon Nut (225) ) in

the Double Pulley Block (207) as shown

in Fig.T3.

4. Continue routing over a pulley in the

bracket in the Top Frame (203) as

Fig T4. and then down to the Top Plate (206).

Screw the threaded end of the Top Cable (220)

into the Top Plate (206)

AT LEAST

one third of

the way. This is a cable adjustment area. When

all cable have been

tightened, make sure

to secure the Jam Nut

to prevent the Top

Cable (220) from

unscrewing.

Low Cable

Route the ball end of the Low Cable (234) under

two pulleys on Weight Base (202) as shown Figs

L1 and L2.. The route Low Cable (234) up and

over bottom pulley (L3) in Double Pulley Block

(207) as Fig. L3. Continue down to the threaded

frame extension welded in Weight Base (202) as

Fig L4.. This is a cable adjustment area. When

all cable have been tightened, make sure to

secure the Jam Nut to prevent the Low Cable

(234) from unscrewing.