8

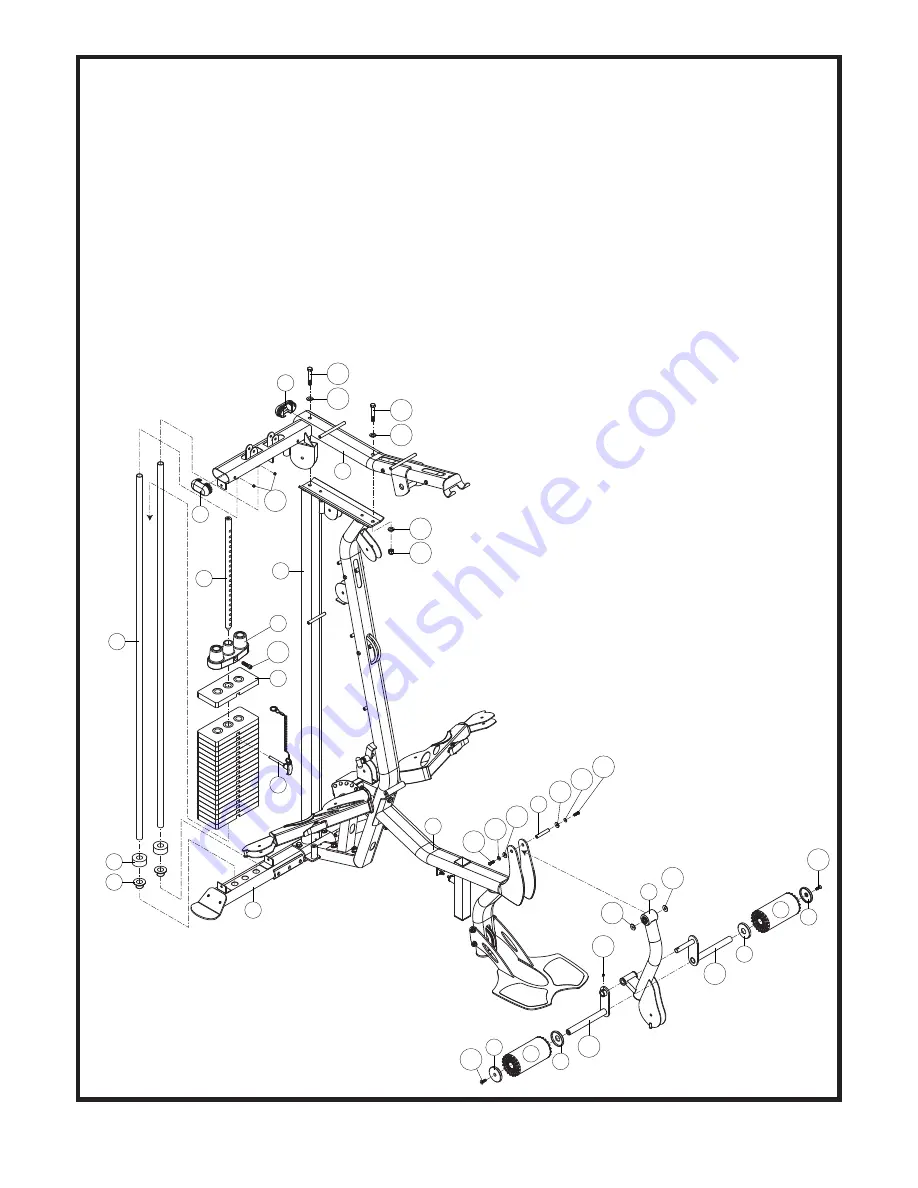

STEP 3 ASSEMBLE TOP FRAME

1

45

78

78

6

47

46

59

3

4

19

83

53

83

84

53

84

29

89

88

2

130

133

116

104

136

144

136

136

104

20L

20R

132

139

138

138

152

152

139

116

123

123

1. Attach Leg Extension Arm with bearing pre-installed (19) to Seat Frame (4), by aligning the

hole and inserting Leg Extension Axle (29). Fasten Leg Extension Axle (29), using two 5/16"

X 5/8" Inner Hex Screws (116), two 5/16" Washers (138), two 5/16" Spring Washers (139).

Check to ensure the Leg Extension Arm (19) pivots freely.

2. Attach the R and L Leg Extension Arms (20R, 20L) to the Leg Extension Arm (19), and

secure using a 5/16" X 1/2" Set Screw (132). Slide a Plastic Cap (83) onto each side of the

R and L Leg Extension Arm (20R, 20L), flat side to the outside. Slide a Foam Pad (53) onto

each Leg Extension Arm (20R, 20L), then cap with an Aluminum Cap (84) and secure with a

5/16" X 1-1/4" Screw (123).

3. Insert two 1" ID Guide Rod Holders (88) into the holes on the Rear Stabilizer (3). Insert the

Guide Rods (6) into 1" ID Guide Rod Holders (88). Slide Rubber Cushions (89) onto the

Guide Rods (6),

then slide Weight Plates (47) onto the Guide

Rod (6), making sure to orient the selector

holes toward the front and bottom.

4. Attach Top Plate (46) to the Selector Rod (45)

using the Top Plate Bolt (130). Tighten the Top

Plate Bolt (130) using a Hex Wrench. Slide

the Top Plate (46) onto the Guide Rods (6),

running the Selector Pin (59) down through the

center holes of the Weight Plates (47).

5. Insert two 1" ID Guide Rod Holders (88) into

the holes in the Top Frame (2). Place the Top

Frame (2) on top of the Main Frame (1) and

Guide Rods (6). Make sure the Guide Rods

(6) are inserted into the 1" ID Guide Rod

Holders (88).

6. Attach two 50 X 100mm Oval Plugs (78) to the

Top Frame (2). Secure the Top Frame (2) to

the Main Frame (1) using two 1/2" X 3"

Hex Bolts (104), three 1/2" Washers

(136), and one 1/2" Nylon Nut (144).