BOGE Operating instructions for C 15 series screw compressors

Page 27

Installation

3.2

Compressor room

Supply and exhaust air ducts

–

Ensure that the flow rates in the ducts do not exceed 157 inches/s.

–

Never position cooling air ducts directly on the compressor. Always use a

compensator to avoid distortion and the transfer of vibrations.

Ventilators

Ensure that the heated exhaust air is not taken in again.

If necessary, the heated air must be extracted by ventilators.

To ensure perfect cooling even at higher temperatures in the summer, the

ventilators must be designed as follows:

–

The ventilator capacity must be rated approx. 10...15% higher than the sum

of the cooling air quantity required for all machines operated in the room.

–

For free-standing installation, the cooling air requirement specified in the

table corresponds to the required ventilator capacity.

Supply air filter

–

The compressor is fitted with supply air filter mats.

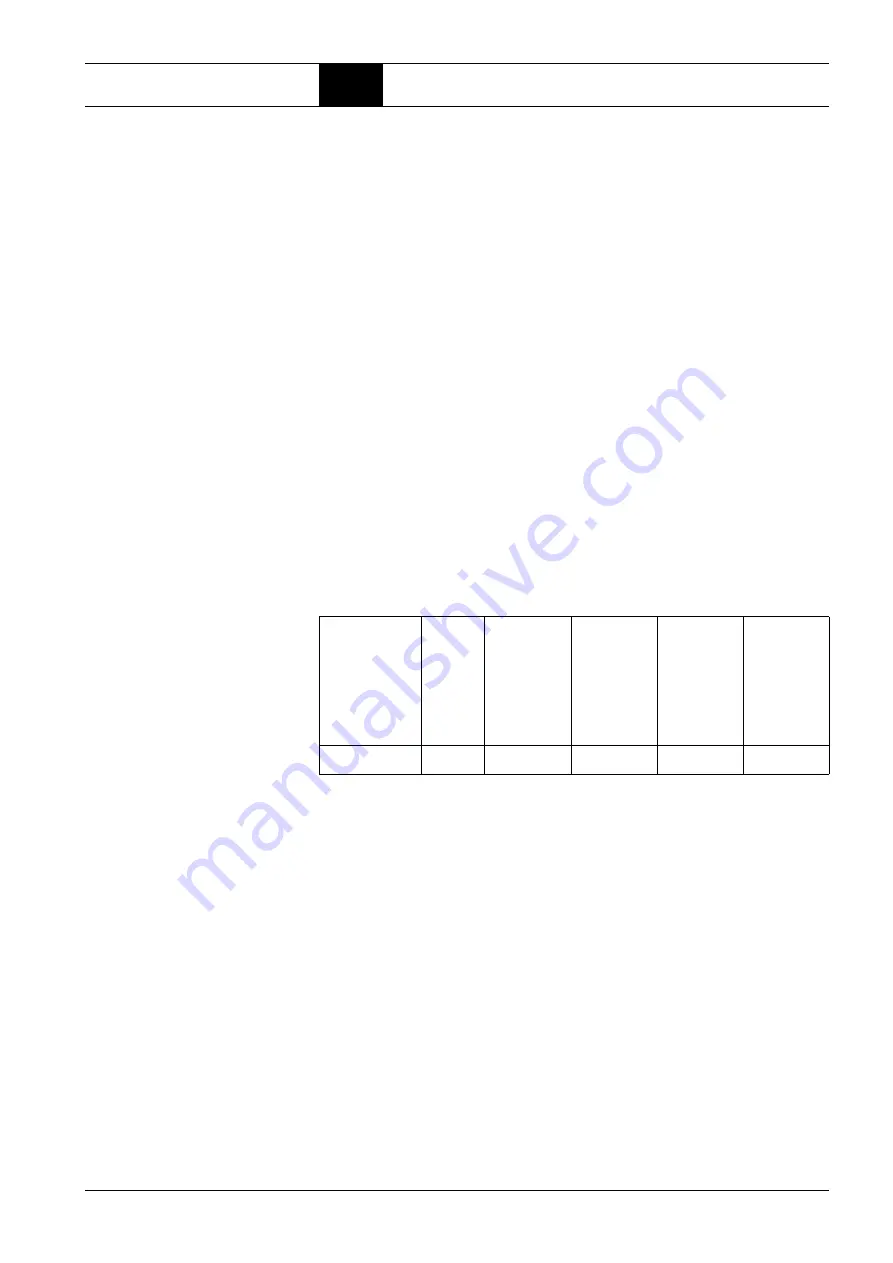

Cooling air requirement

Please refer to the following table for the cooling air requirement and size of

the supply air openings for your compressor. Ensure that flaps and weather

protection grids have the necessary free cross section. We generally recom-

mend contacting a specialist company for performing the duct construction

work and planning.

* For the cooling air requirements the basis is a 39°F temperature difference between room and outside temperature.

Tab. 3.1: cooling air requirement, necessary cross sections for openings and

ducts

Type

Drive

rating

* Cooling air

requirement

for free

standing unit

Necessary

inlet

opening

for free

standing unit

* Cooling air

requirement

for instal-

lation with

ducting

Necessary

free duct

cross section

[Hp]

[cfm]

[sq. ft.]

[cfm]

[sq. ft.]

C 15 / C 15 F

15.0

2180

5.4

1002

1.2