BOGE Operating instructions for C 15 series screw compressors

Page 61

Maintenance

6.3

Maintenance work compressor

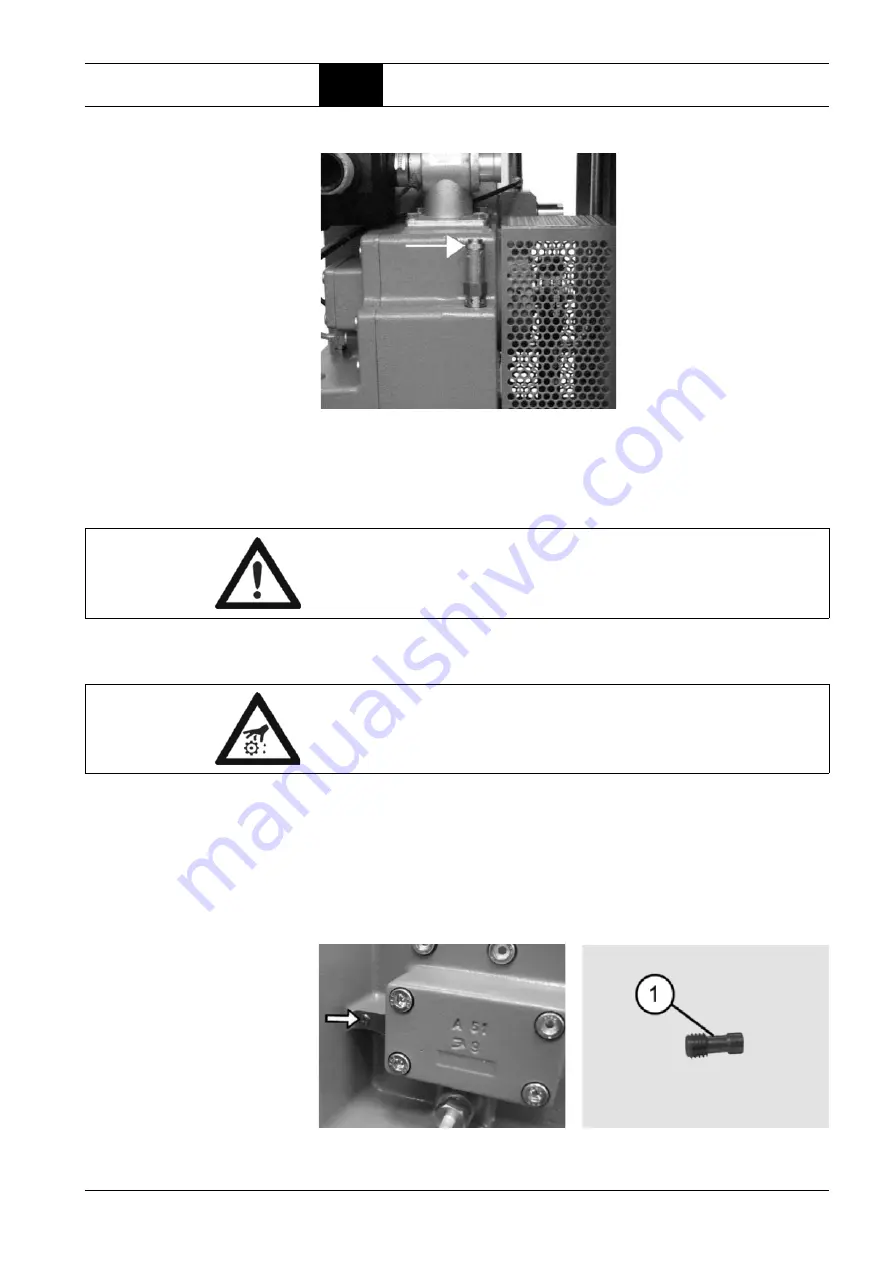

Fig. 6.10: Lock nut on safety valve

Nozzle with dirt catch

Change:

–

After 3000 operating hours, however, no later than after one year.

–

Switch off the compressor using the OFF button.

–

Close ball valve at the compressed air outlet.

–

Open safety sound insulation hood.

–

Vent the compressor (as described in the beginning of the chapter).

–

Wait approx. 3 minutes to permit the oil to settle.

–

Unscrew nozzle with dirt catch (see arrow) (1).

–

Screw in new nozzle with dirt catch.

Fig. 6.11: Nozzle with dirt catch

–

Open the threaded plug

(see arrow) anticlock-

wise. The air/oil mixture

escapes.

–

Tighten the threaded plug

by turning clockwise.

WARNING!

If the prescribed maintenance interval is not observed, the residual oil con-

tent in the compressed air increases considerably.

WARNING: Risk of injury!

Prior to any maintenance and servicing work take all necessary safety pre-

cautions described on page 44!