Magnetics that count

BOGEN Magnetics GmbH

· Potsdamer Straße 12 - 13 · 14163 Berlin · Germany

Fon +49 (0) 30 81 00 02 - 0 · Fax +49 (0) 30 81 00 02 - 60 · magnetics@bogen-magnetics.com · www.bogen-magnetics.com

AKS17 ins

tallation and oper

ation ins

truction manual (2021/06/16)

9/14

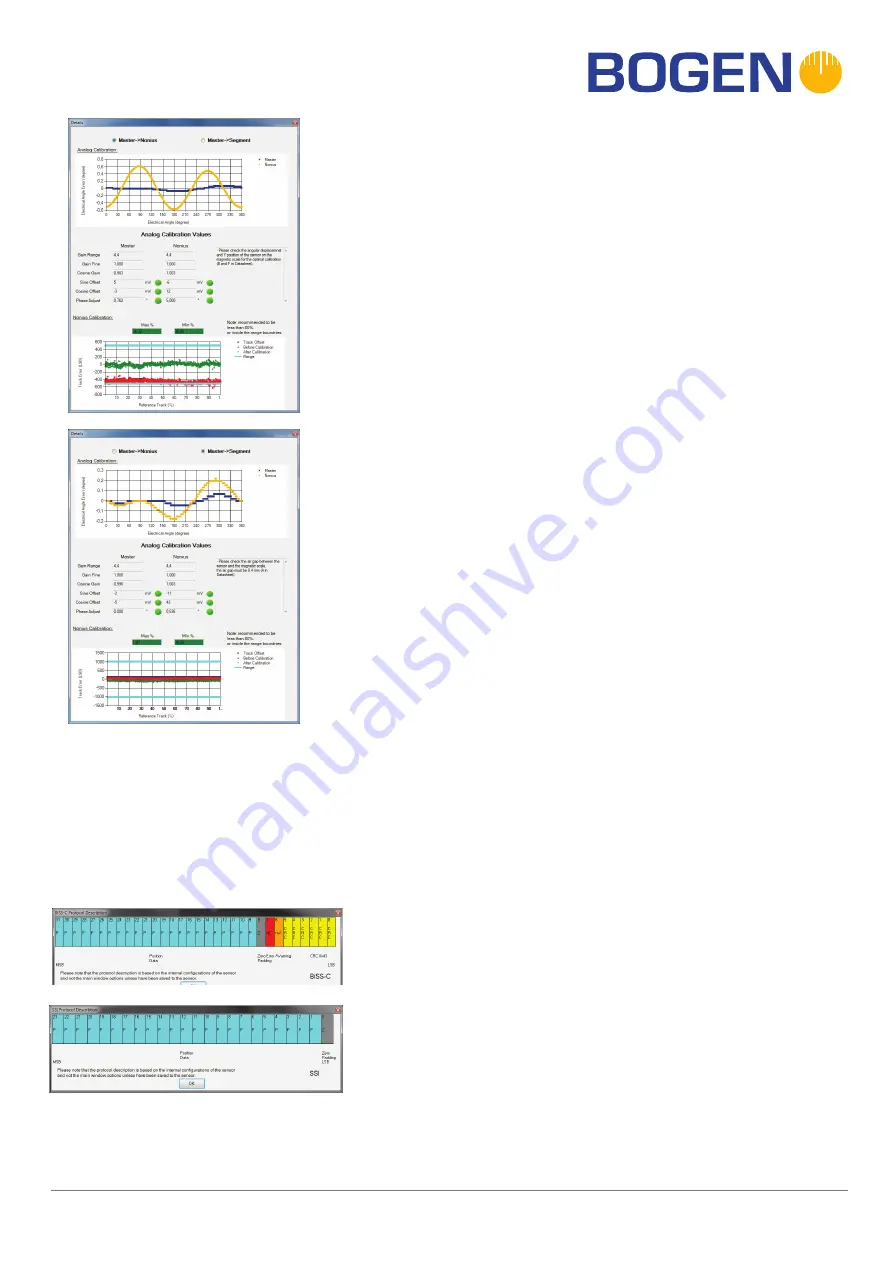

In the “Details” window the user can check the calibration charts

and calibrated analog values. The “Details” window consists of three

sections:

1. Analog calibrations

A good calibration should center both graphs, Master and Nonius, as

close as

possible to zero. The smaller the amplitude, the better the calibration.

In case the analog electrical angle error is more than 12° the analog

calibration is considered to be failed.

2. Analog calibration values

Analog calibration values are automatically calculated and set in

the sensor.The user cannot change them but he can read them for

verification purpose. A green circle next to the value means that the

value is within the recom-

mended range. Otherwise the circle is red and in the textbox to the right

the

user can see the corresponding error message.

3. Nonius calibration

Max% and Min% represent the maximum and minimum percentage

value from result regarding the range. If marked green, they are less

than 80% of the range. If marked orange, they are between 80% and

100%. Otherwise the mark is red. It is recommended to keep them

less than 80% of the range. A better calibration has values of “Result”,

“Error” and “Track” closer to zero.

AKS17 23-Bit BiSS-C data packet information example.

Note that the red nE and the orange nW are active low bits.

Protocol Data Packet Information

The protocol data packet can be shown by connecting the sensor and then clicking on “Help” in the menu.

After clicking on “Show Protocol Data Packet” the currently saved internal protocol configuration that has

been set inside the sensor in both BiSS and SSI protocols will be shown.

The following two figures are examples of BiSS-C and SSI protocol packets

AKS17 23-Bit SSI data packet information example.

The data packet information in the window can be saved as a png-image-file by clicking on the graphic and

choosing a disc place to save it.