Maintenance every 6 months

BOMAG

45

BPH 80/65

Fig. 50

l

Dry clean the entire cooling air area like cylin-

der head, cylinder flywheel blower and blow it

out with compressed air (Fig. 50) .

Wet or oily dirt

!

Danger

Fire hazard!

Do not use any inflammable solvents.

!

Caution

Do not spray directly on electric assemblies

and plug connectors or dry them with com-

pressed air immediately after.

Find the cause of oily dirt and have leaks

sealed by the after sales service of BOMAG.

Do not hold the water jet directly into the air fil-

ter, the exhaust and the electric system (if

present).

l

Disconnect the battery

*

.

l

Spray the entire cooling air area with cleaning

solution (e.g. cold cleansing agent), let it soak

in for a while and clean off with a sharp water

jet.

l

Run the engine warm for a short while to avoid

corrosion.

4.17 Check the oil level in the vi-

brator housing

i

Note

Park the machine on level ground.

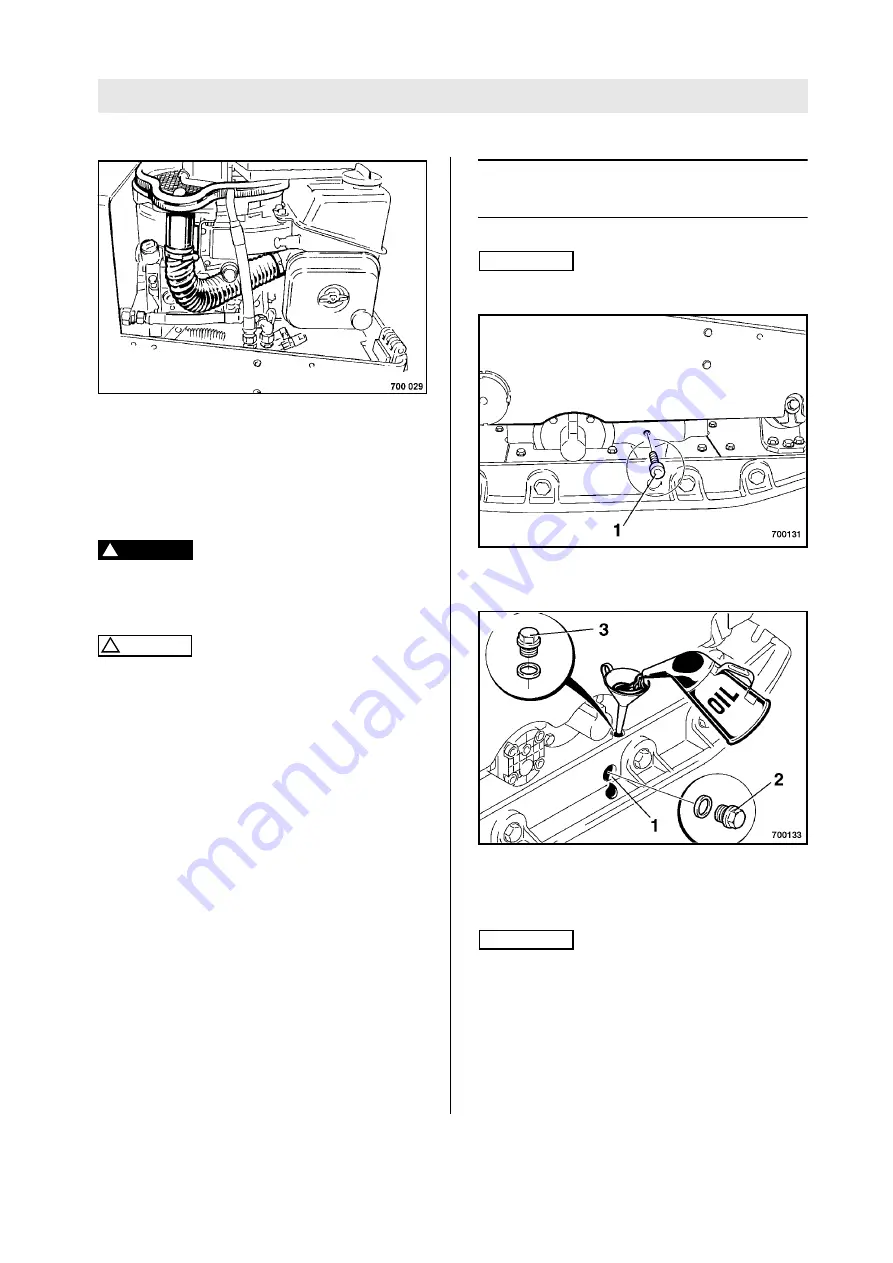

Fig. 51

l

Unscrew bleeding screw 1 (Fig. 51).

Fig. 52

l

Unscrew oil level inspection plug 2 (Fig. 52)

and check the oil level.

i

Note

Some oil should run out of the oil level inspection

bore (1).

l

If necessary top up oil. For this purpose un-

screw filler plug (3) and fill in oil.

l

Screw in filler plug (3) back in.

*

Option

Summary of Contents for BPH 80/65

Page 2: ......

Page 6: ...Table of Contents BOMAG 6 BPH 80 65 ...

Page 7: ...BOMAG 7 BPH 80 65 1 Technical Data ...

Page 11: ...BOMAG 11 BPH 80 65 2 Safety regulations ...

Page 16: ...Safety regulations BOMAG 16 BPH 80 65 ...

Page 17: ...BOMAG 17 BPH 80 65 3 Operation ...

Page 28: ...Operation BOMAG 28 BPH 80 65 ...

Page 29: ...BOMAG 29 BPH 80 65 4 Maintenance ...

Page 53: ...BOMAG 53 BPH 80 65 5 Trouble shooting ...

Page 57: ......

Page 58: ......