Maintenance every year

BOMAG

49

BPH 80/65

4.20 Changing the oil in the vi-

brator housing

Environment

Catch running out old oil, do not let it seep into

the ground and dispose off environmentally.

l

Tilt the machine towards the drain side and

support it securely.

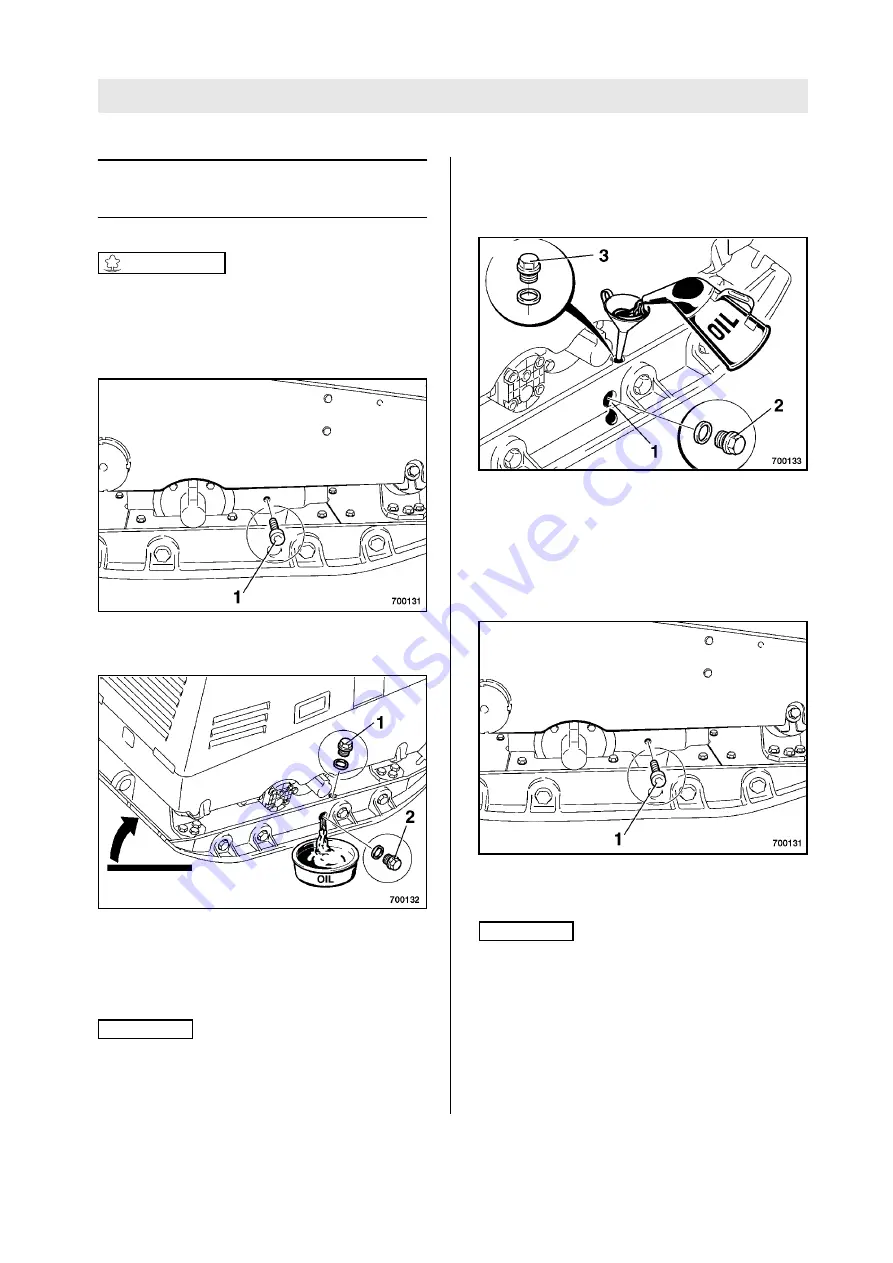

Fig. 60

l

Unscrew bleeding screw 1 (Fig. 60).

Fig. 61

l

Unscrew filler plug 1 (Fig. 61) as well as level

and drain plug (2).

l

Drain off and catch old oil.

i

Note

Leave the machine in this position until all oil has

run out of the drain bore.

For quality and quantity of oil refer to the table

of fuels and lubricants.

l

Stand the machine horizontally.

Fig. 62

l

Fill in oil, until oil starts to run out through in-

spection bore 1 (Fig. 62).

l

Clean inspection and drain plug (2) and screw

it back in with a new seal ring.

l

Screw in filler plug (3).

Fig. 63

l

Turn in bleeding screw 1 (Fig. 63).

i

Note

If the seal ring on the bleeding screw is worn use

a new bleeding screw with seal ring.

Summary of Contents for BPH 80/65

Page 2: ......

Page 6: ...Table of Contents BOMAG 6 BPH 80 65 ...

Page 7: ...BOMAG 7 BPH 80 65 1 Technical Data ...

Page 11: ...BOMAG 11 BPH 80 65 2 Safety regulations ...

Page 16: ...Safety regulations BOMAG 16 BPH 80 65 ...

Page 17: ...BOMAG 17 BPH 80 65 3 Operation ...

Page 28: ...Operation BOMAG 28 BPH 80 65 ...

Page 29: ...BOMAG 29 BPH 80 65 4 Maintenance ...

Page 53: ...BOMAG 53 BPH 80 65 5 Trouble shooting ...

Page 57: ......

Page 58: ......