D

ELUXE

W

ALL

F

URNACE

Page 17

Unit Commissioning

S

ETTING

G

AS

P

RESSURES

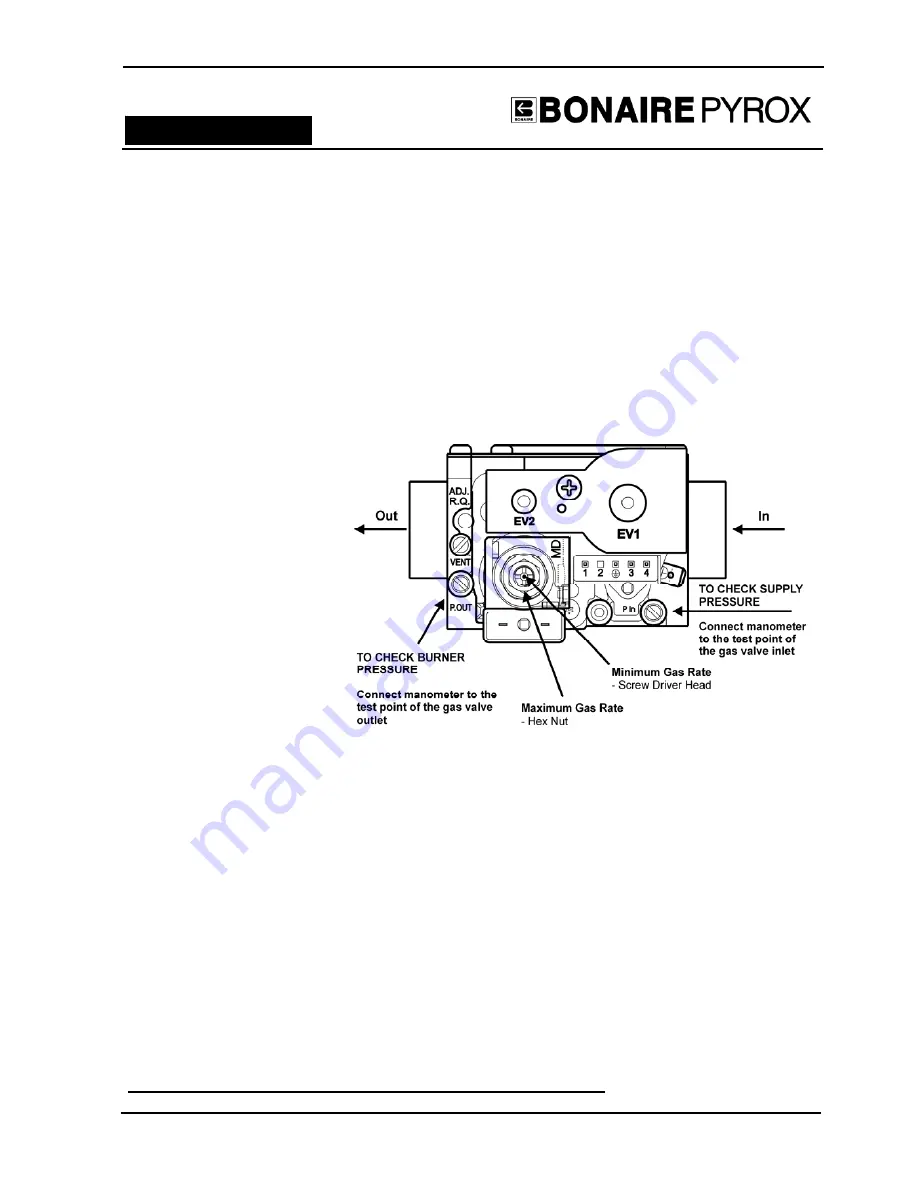

Checking the Dynamic Gas Pressure

To check dynamic gas pressure

1. Loosen the test point screw “P IN”

2. Fit the manometer tube and check the reading against the stated supply pressure on the

customer’s supply regulator.

3. If the correct supply pressure is not available, contact the local gas authority to obtain the

correct pressure.

4. Remove the manometer tube. Tighten the test point screw and check for leaks.

Burner Pressure - Modulating

Setting the burner pressure is

done in 2 parts. The high

pressure must always be set

before the low pressure can

be correctly established.

Loosen the test point screw “P

OUT” and connect the

manometer.

When adjusting either

maximum or minimum gas

rate, ensure the adjuster not

being set is secured e.g. when

adjusting the maximum gas

rate, use a screwdriver to hold

the minimum gas rate adjuster

from moving.

Setting the Maximum Burner Pressure

1. To adjust the maximum burner pressure, set unit to high fan/gas using the mode key, use a

spanner on the hexagon nut and adjust in small increments.

2. Screw the adjuster clockwise to increase pressure, anti-clockwise to decrease burner

pressure.

3. If the heater has been running for a while, the thermistor may be turning down the gas

rate. To check the full gas rate, press down the pin in the middle of the minimum gas rate

screw head. You will need something the diameter of a 1/8” rivet shank.

See Technical Specification section for burner pressures

Setting the Low Burner Pressure

1. To check and or set the minimum gas rate, remove one of the black low voltage leads to

the gas valve.

2. Adjust the gas rate in small increments to the specifications using a Phillips head

screw driver.

3. Replace the black low voltage lead removed to the gas valve.

RETIGHTEN TEST POINT SCREW AND CHECK FOR GAS LEAKS