4

Flash coil steam generators of the series UNI-MATIC

(UM) with forced circulation guarantee a steam

production range between 300 and 3000 kg/h; design

pressure is up to 12 bar.

Models of the steam generators series UNI-MATIC:

•

UM 30: up to

300 kg/h

•

UM 50:

up to

500 kg/h

•

UM 100:

up to

1.000 kg/h

•

UM 150:

up to

1.500 kg/h

•

UM 200:

up to

2.000 kg/h

•

UM 300:

up to

3.000 kg/h

UM-UNIMATIC UM flash coil steam generators’ fields

of application are laundries, texile industry, food &

beverage, rubber, cellulose industry, agrotechnology,

woodworking and others.

UNI-MATIC UM generators are supplied as packaged

units, complete with all necessary equipment and

ready to be connected to site utilities.

As optional, an air preheater can be purchased

additionally to the steam generator.

Preheater enables the boiler to increase efficiency by

2%, therefore reaching 90% at full load.

UM model reaches operating conditions 2-3 minutes

after ignition of the burner.

UNI-MATIC model UM is available both in vertical and

horizontal version - UM compact design is also suitable

for small plants, although always guaranteeing high

quality performances.

UNI-MATIC UM generators are deisgned and produced

according to ISPELS code, PED directive 97/23/CE

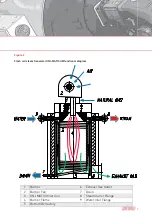

Figure 1

Flash Coil Steam Generator UNI-MATIC

UM, vertical version with air pre-heater

1. GENERAL INFORMATION

Figure 2

Flash Coil Steam Generator UNI-MATIC

UM, horizontal version