14

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

9 On-site

adjustment

An on-site adjustment is carried out if an error has been confirmed due to certain on-site conditions after

the reasons according to section 13.1 have been checked. By changing the transducer constant K

0

, a

simple adjustment can be performed.

Example: Measurement

condition

Temperature must be relatively stable

Rho (measured density) = 996.6 Kg/m³

Rho (setpoint value)

= 996.0 Kg/m³ (e.g. value stated in table)

difference (misalignment) = +0.6 Kg/m³

current

K

0

value

= -7360.708 Kg/m³

setpoint K

0

value

= K

0

(current) –

misalignment

correct

K

0

value

= - 7360.708 Kg/m³ - 0.6 Kg/m³

= -7361.308 Kg/m³

Now this value must be entered into the transmitter type TR.

If possible, the constants K

1

and K

2

should not be modified by the user.

Depending on the operating mode or application and the reason for the error, the adjustment can also be

carried out via the concentration coefficient K

X0

. Here the same procedure is applied.

10 Configuration, operation

The transmitter can be configured (operated) in two different ways:

1.

HART

communication

2. On-site operation with keys and display

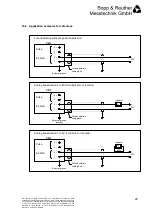

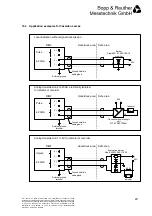

10.1 Operation via HART

communication

The device can be operated using a PC or laptop and the SensorPort 2 configuration software in

connection with a HART

interface.

A HART

Communicator is another operating element which can be used (e.g. model HC-275 of

Rosemount). The operating functions of the HC-275 are defined in the HART "Device Description

Language" (DDL). Using the HC-275 the DIMF can be operated or configured on site. For the electrical

connection, see section 16.1.