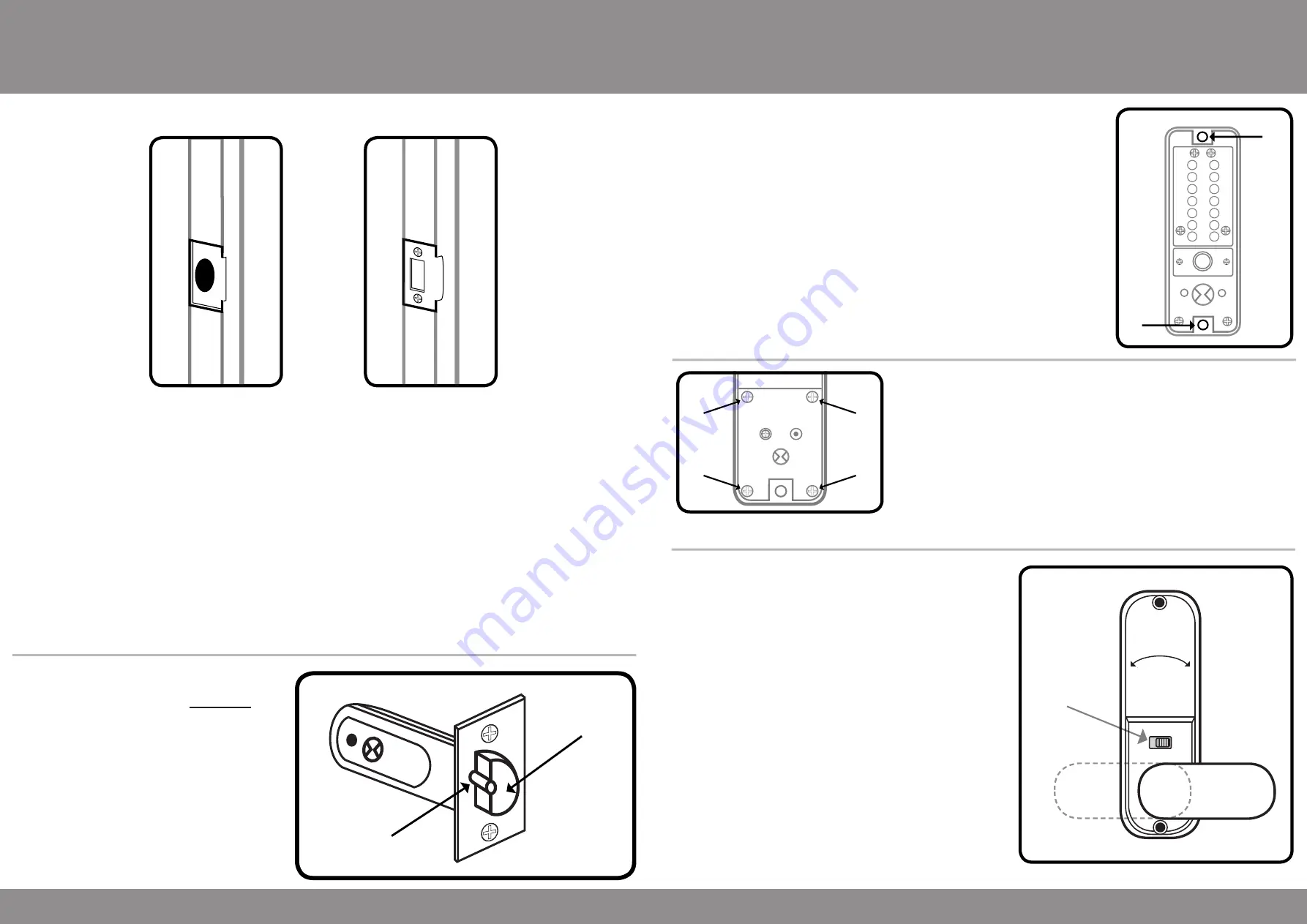

Fitting the Hexagonal Support Posts

Fit both of the hexagonal support posts

(part no.9)

into the top and bottom

threaded holes of the keypad, as shown in the diagram.

Do not over tighten the hexagonal support posts as this may strip the

thread on either the post itself or the thread in the back of the keypad.

1

2

3

4

5

X

Y

6

7

8

9

0

Z

C

A

B

V3

3

Removing the Holdback Function

If you do not require the holdback function on the inside handle

(holback

models model only)

this feature can be removed.

On the back of the inside handle

(part no. 2)

, unscrew all of the screws as

shown on points

A

,

B

,

C

and

D

on the diagram.

With the 4 screws removed the plate can now be lifted out of position, this

will reveal the holdback snib, which has a spring and ball bearing attached.

Remove the holdback snib, spring and ball bearing and place the hold back

snib blank

(part no. 7)

in the hole.

A

B

C

D

V3

Preparation

Installation

6

Fitting the Strike Plate & Box Keep

Anti-Thrust Pin

Latchbolt

Push the door to the closed position and mark the area on the frame of the door where the strike plate would need

to be fitted.

Open the door and now mark the innner and outer edges of the strike plate. Using a sharp chisel remove 1mm of

material from the frame of the door

until the strike plate can sit flush.

With the material for the strike plate removed from the frame of the door, the material for the box keep will need to

be removed. Place the box keep in the cut-out made for the strike plate and draw around the box keep. You will

need to remove 36mm high, 23mm wide and 13mm deep of material to accommodate the box keep, alternatively a

20mm diameter by 15mm deep hole can be drilled in the frame to allow the latchbolt to fully protrude when the door

is in its closed position.

To secure the strike plate and box keep in place use two of the wood screws

(part no. 14)

. Now that the strike and

the box keep have been secured in place the door can be closed. Ensure that the keypad and inside handle with-

draw the latch when the door is in its closed position.

If the operation of the lock is excessively stiff when turning the keypad or inside handle, the strike plate

and box keep position will need to be adjusted.

Please note the anti-thrust beside the latchbolt (as

per the diagram), this deadlocks the latchbolt and

protects it against manipulation.

It must not

enter

the hole made for the latchbolt when the door is

closed.

If the anti-thrust pin does go into hole for the

latchbolt, adjust the position of the strike plate

until the anti-thrust pin sits on the face of the

strike plate.

Operating the Holdback Function

To operate the holdback function the handle will need be

turned a full 90° to the left or right (depending on the handing

of the door.

If the unit is fitted to a left hand hung door the handle will need

to be turned to the right (clockwise) and the snib will need to

be pushed to the left. When the snib has been pushed across

the handle will stay in the rotated position and the latchbolt in

the edge of the door will be withdrawn.

If the unit is fitted to a right hand hung door the handle will

need to be turned to the left (anti-clockwise) and the snib

will need to be pushed to the right. When the snib has been

pushed across the handle will stay in the rotated position and

the latchbolt in the edge of the door will be withdrawn.

To release the holdback function a small amount of pressure

will need to be applied to the handle to allow you to push

the snib across. With the snib pushed across the handle will

spring back to its vertical position and the latchbolt in the edge

door will now be visible.

Holdback

Snib