BORLA PERFORMANCE INDUSTRIES

500 Borla Drive

Johnson City TN, 37604-7523

805-986-8600

DOCUMENT PART NUMBER

A-35805 Rev. B

INSTALLATION INSTRUCTIONS

Volkswagen Golf GTI

PAGE

4 of 4

NOTE: When you first start your vehicle after the installation of your new Borla Performance Exhaust

System, there may be some smoke and fumes coming from the system. This is a protective oil based coat-

ing used in the manufacturing of mandrel bent performance exhaust tubing. This is not a problem and

will disappear within a very short period of time after the exhaust has reached normal operating temper-

atures.

WARNING: Use extreme caution during installation. Torque all fasteners according to manufactur-

er’s torque values and tightening sequence. DO NOT use air impact tools to tighten fasteners on

Borla Performance

Exhaust

Systems. Use of such tools may result in bent flanges or gasket contact

areas leading to exhaust leaks.

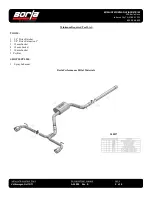

Borla Performance Cat-Back

Exhaust System Installation

1. Insert the

Front Pipe

into the OE band clamp. Slide and position the clamp

with the bolts accessible to tighten later. Do not tighten these bolts.

2. Place a 2.50” Accuseal clamp over the

Muffler Assembly

and insert into

the

Front Pipe

. Insert hanger into rubber isolators.

3. Place the 2.50” Accuseal clamp over the

Y-Pipe Assembly

and insert inlet

into the

Muffler Assembly

. Insert hanger into rubber isolators. (See Fig. 4)

4. Place a 2.00” Accuseal clamp over the

L/H Tail Pipe Assembly

and insert

inlet into the

Y-Pipe Assembly

. Insert hanger into rubber isolators. (See

Fig. 5)

5. Slide the Accuseal clamp over the notches and rotate the clamp-bolt 90-

degress from the notches. The clamp-bolt should be positioned between the

notches. (See Fig. 6) Do not tighten tighten this bolt.

NOTE: When

properly clamped, the Accuseal pipe closes in a circular-shape with inter-

locking notches creating a proper seal. The pipe will distort or ovalize in

shape if the clamp-bolt is positioned over the notches.

6. Check your exhaust system for proper clearance under the vehicle and also

for tip alignment. Once position has been determined to be correct, tighten

the Accuseal™ clamp 32-35 ft. lbs. Tighten the OE clamp bolts. (See Fig.

7)

7. Start vehicle and check for any leaks. If any leaks are found, determine

cause (such as loose or incorrectly positioned clamp) and repair as neces-

sary.

4

5

6

7