15

www.BormannTools.com

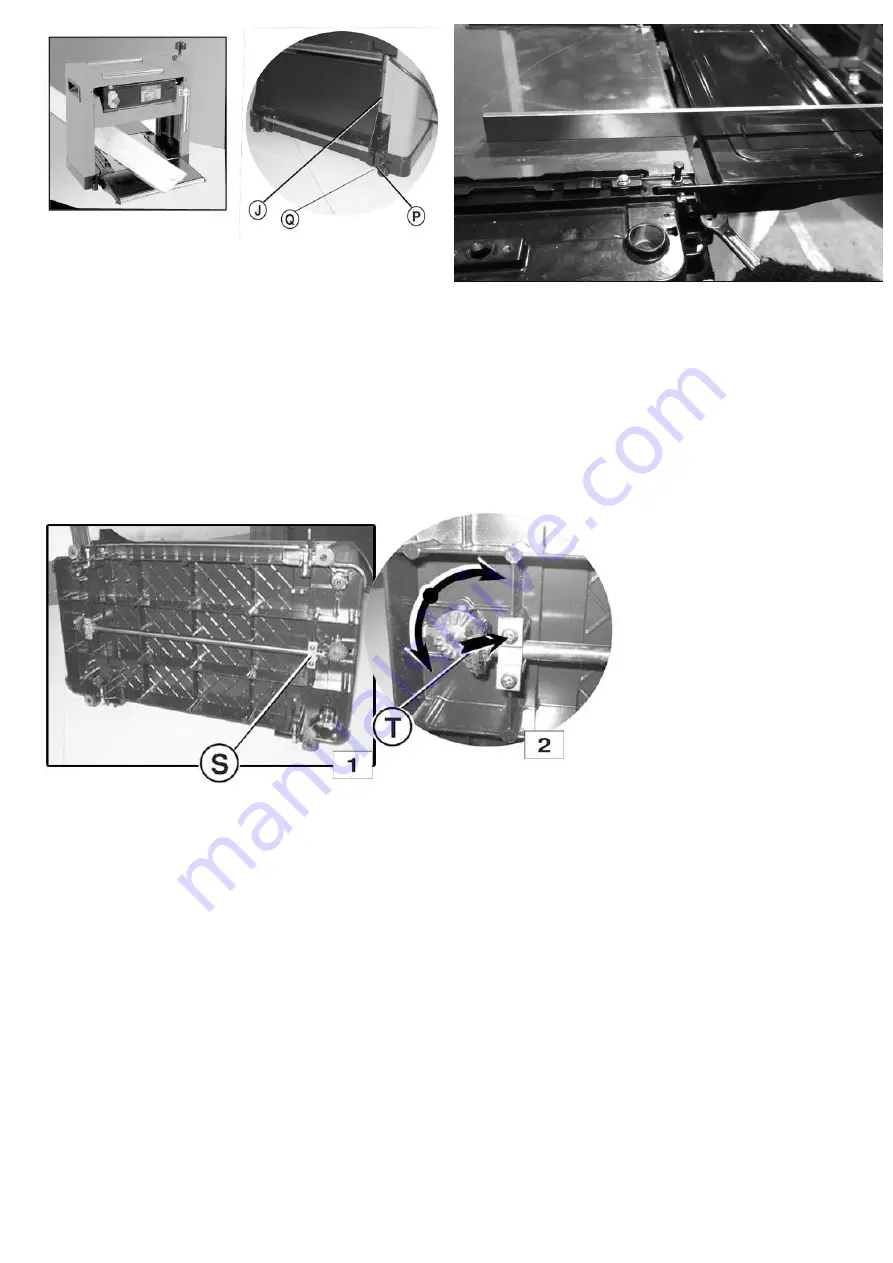

PARALLELISM ADJUSTING

ATTENTION:

T

his adjustment is already factory set ok.

In

order to avoid to effecting the function of the machine.

Need

to check again.

Poor parallelism is usually caused by misaligned blades. Alw

ays check that the blade holder and the work table parallel

before attempting to adjust the parallelism setting.

1. Place the machine on its side and rotate the cross rod bearings (S)

fig.1 .

2. Move the conical gear wheel (T) towards the clamp until

it runs freely from the second gear w

heel (fig.2).

3. Turn the second gear wheel to adjust the height of the bla

de holder on the side where the gear wheels are located.

One tooth shifting anti

-clockwise raises the blade holder 0.1mm

(H).

Replacing and adjusting

the blades

WARNING! Turn off the machine, unplug the power cord and wait

until all moving parts have stopped completely

before replacing or adjusting the blades.

Dismantling the knife blade

1. Use

Allen

wrench (N) to remove the dust hood (V) by loosening the screws (U), see below

picture.

2. Use the double open wrench (N) to lo

osen the blade lockin

g plate (B) and knife blade (C)

by turning the outer

hexagon bolt (A) clockwise. The knife b

lades are spring-lo

aded (D) and

can be remove when the blade locking plate is

removed.

3. Remove the knife blade and blade locking plate.