01/20

B2003T

Made in China to TQB Brands Pty Ltd specifications

P a g e

|

2

Visit us at www.tqbbrands.com.au

STANDARD OPERATING PROCEDURE

DO NOT

use this machine unless you have been trained and assessed to a competent level in its safe use and operation, and

have been given permission to use this

PRE-OPERATIONAL SAFETY CHECKS

•

This Truck Jack should be used for lifting and lowering only. The raised vehicle should be

supported on approved vehicle stands. No person should get any part of the body under a vehicle

that is supported by this jack.

•

Position the jack to only lift on the areas of the vehicle specified by the vehicle manufacturer.

•

Use support stands – after lifting the vehicle always support the load with appropriately rated

vehicle support stands before working on the vehicle.

•

Do not overload this jack beyond its rated capacity. Overloading this jack beyond its rated

capacity can cause damage to or failure of the jack.

•

Use only on hard level surfaces capable of sustaining the load. Use on other than hard level

surfaces can result in jack instability and possible loss of load.

•

Centre load on jack saddle before lifting vehicle.

•

Off centre loads and loads lifted when the jack is not level can cause loss of load or damage to

the jack.

•

Keep hands & feet clear of the jack hinge mechanism & ground contact area when lowering the

load.

THIS JACK IS A LIFTING DEVICE ONLY & IS DESIGNED FOR LIFTING PART OF THE TOTAL

VEHICLE. DO NOT MOVE OR DOLLY THE VEHICLE WHILST THE VEHICLE IS ON THE JACK.

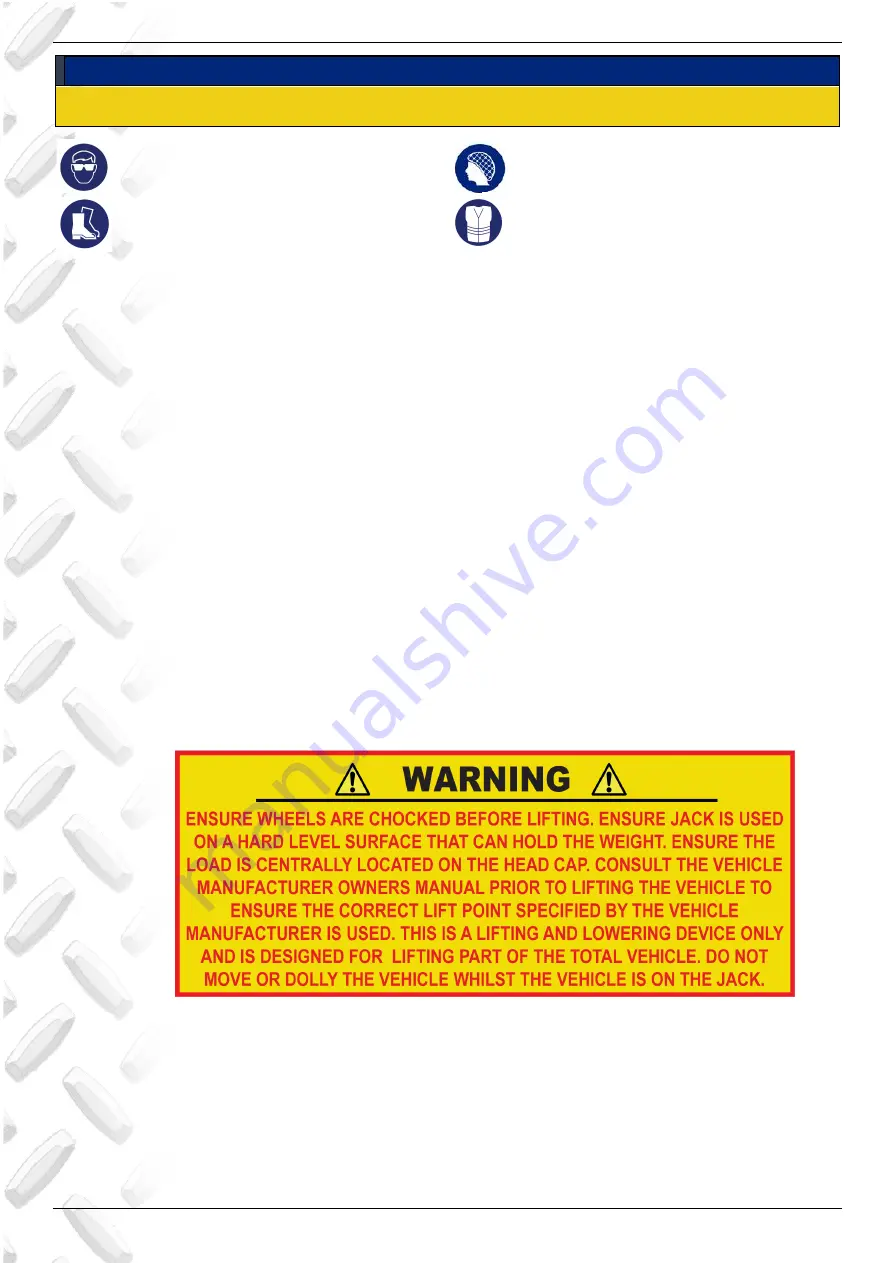

Safety glasses must be worn when

operating this equipment

Long loose hair must be contained when

operating this equipment

Safety footwear must be worn when

operating this equipment

Close fitting/protective clothing must be

worn when operating this equipment