20

| English

ing lever

(1)

upward and rotate the protective guard

(7)

into

the required position.

u

Always position the protective guard

(7)

such that all

three red cams on the unlocking lever

(1)

engage in

the corresponding openings on the protective guard

(7).

u

Adjust the protective guard

(7)

such that sparking in

the direction of the operator is prevented.

u

The protective guard

(7)

must only be adjustable

while the unlocking lever (1)

is actuated. Otherwise,

the power tool must not be used any more under any

circumstances and must be sent to the after-sales ser-

vice.

Note:

The coding cams on the protective guard

(7)

ensure

that only a protective guard that is suitable for the power

tool can be fitted.

Protective guard for cutting

u

Always use the protective guard for cutting (9) when

cutting bonded abrasives.

u

Provide sufficient dust extraction when cutting stone.

The protective guard for cutting

(9)

is fitted in the same way

as the protective guard for grinding

(7)

.

Extraction guard for cutting with a guide block

The extraction guard for cutting with a guide block

(18)

is fit-

ted in the same way as the protective guard for grinding

(7)

.

Side handle

u

Do not operate your power tool without the side

handle

(6)

.

Screw the side handle

(6)

on the left or right of the machine

head depending on how your are working.

Hand guard

u

Always fit the hand guard (14)

when working with the

cup brush/disc brush

(15) or diamond core cutter

(20).

Attach the hand guard

(14)

to the auxiliary handle

(6)

.

Fitting and removing abrasive tools

u

Pull the plug out of the socket before carrying out any

work on the power tool.

u

Do not touch grinding and cutting discs until they have

cooled down.

The discs can become very hot while work-

ing.

u

Only use original X-LOCK application tools that carry the

X-LOCK logo. A maintained clamping gauge of max.

1.6 mm can only be guaranteed with original X-LOCK ap-

plication tools. A higher clamping gauge can lead to insec-

ure clamping, potentially causing the clamp tool to come

loose.

u

X-LOCK application tools do not need additional clamping

flanges or support flanges.

u

Make sure that the application tool and the holder are not

deformed and are free from dirt and particles.

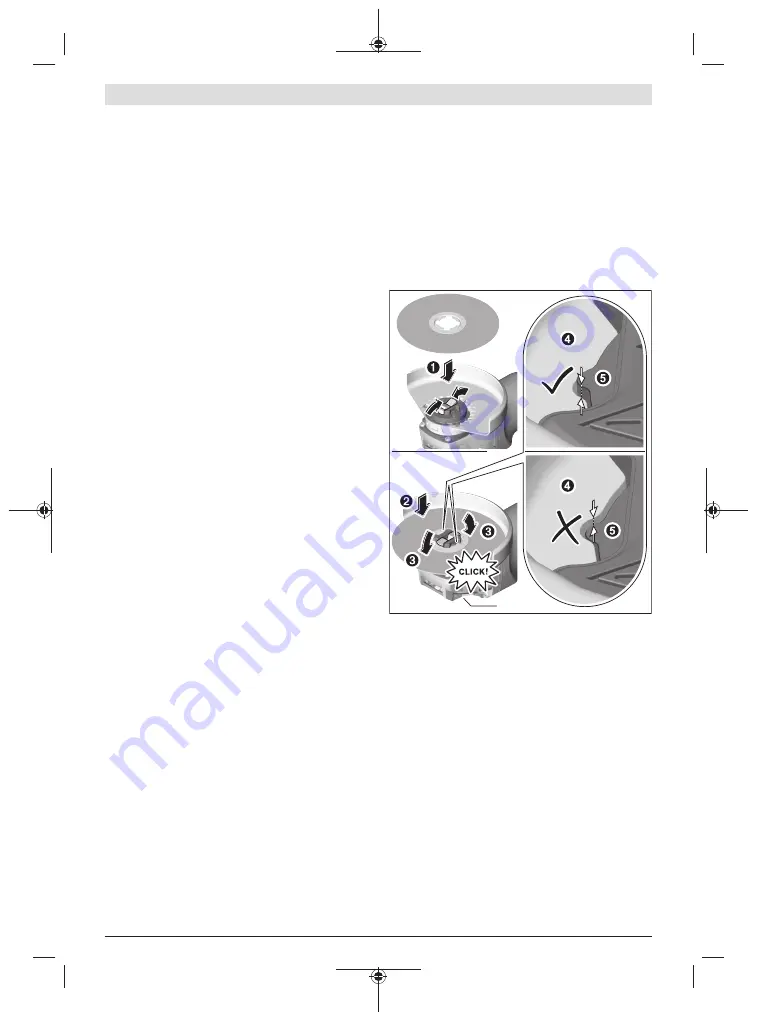

Pay attention to the dimensions of the abrasive tools.

Make sure that

both

X-LOCK catches are open (see figure

below) before fitting the X-LOCK application tool.

If necessary, clean the area between the two X-LOCK

catches.

Fitting the abrasive tool

➊

Place the grinding/cutting/flap disc in a central position

on the X-LOCK holder, parallel to the bearing surface

and with the right side facing up.

➋

Push the disc into the holder.

➌

The disc audibly clicks into place. Do not actuate the

lever

(3)

when doing so.

(3)

u

After fitting, check that the edge of the abrasive tool

(

➍

) is fitted correctly, i.e. is no higher than the refer-

ence surface (

➎

). If the edge is higher than the refer-

ence surface, either the holder must be cleaned or the

abrasive tool must not be used.

Before removing the grinding/cutting/flap disc:

Make

sure that the power tool has come to a complete stop.

Removing the abrasive tool

➊

Open the lever

(3)

.

➋

The grinding/cutting/flap disc will be released.

➌

The grinding/cutting/flap disc can be removed.

1 609 92A 4FA | (21.01.2019)

Bosch Power Tools

Summary of Contents for 0.601.7B2.000

Page 3: ... 3 Bosch Power Tools 1 609 92A 4FA 21 01 2019 ...

Page 4: ...4 6 1 2 3 4 5 6 7 8 9 10 1 609 92A 4FA 21 01 2019 Bosch Power Tools ...

Page 300: ...300 آفارسی 1 609 92A 4FA 21 01 2019 Bosch Power Tools ...

Page 301: ... 301 ø 22 23 mm Bosch Power Tools 1 609 92A 4FA 21 01 2019 ...

Page 304: ...304 1 609 92A 4FA 21 01 2019 Bosch Power Tools ...