22

| English

The power tool must always

work in an up-grinding mo-

tion. Otherwise, there is a

risk that it will be pushed

uncontrolled

out of the cut.

For best results when cut-

ting profiles and rectangular

tubing, start at the smallest

cross section.

Cutting stone

u

Provide sufficient dust extraction when cutting stone.

u

Wear a dust mask.

u

The power tool may be used only for dry cutting/grind-

ing.

For best results when cutting stone, use a diamond cutting

disc.

When using the extraction guard for cutting with a guide

block

(17)

, the vacuum cleaner must be approved for vacu-

uming stone dust. Suitable vacuum cleaners are available

from Bosch.

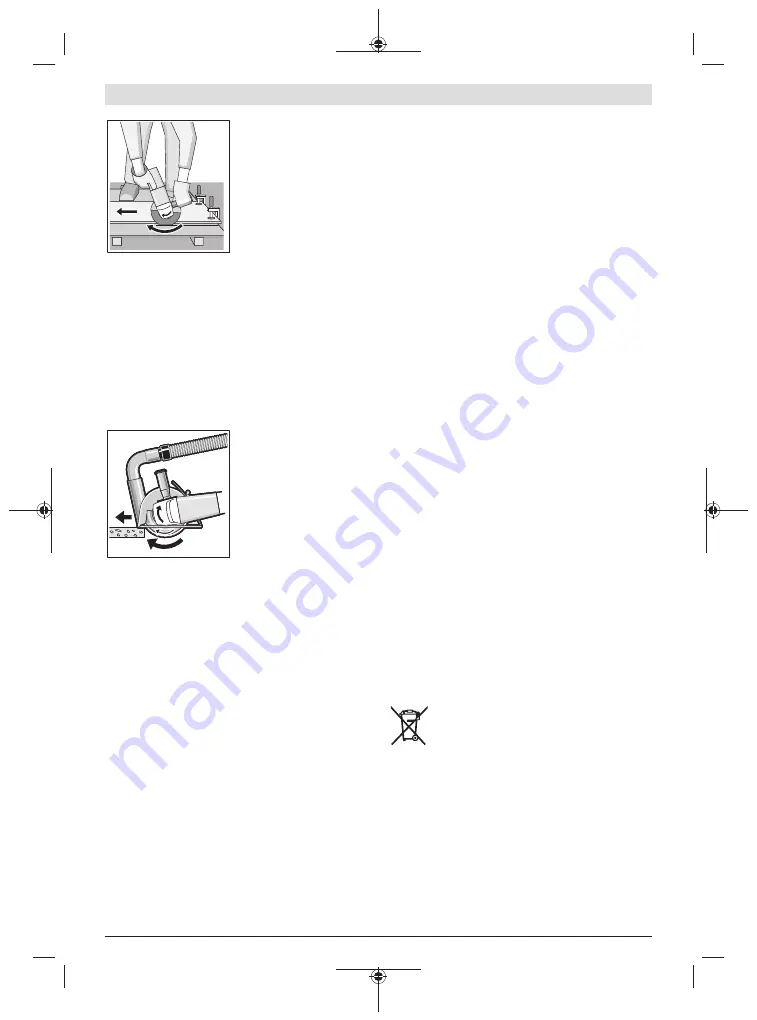

Switch on the power tool

and position it with the

front part of the guide block

on the workpiece. Move the

power tool with a moderate

feed motion that is suited to

the material being ma-

chined.

When cutting especially

hard materials such as con-

crete with a high pebble content, the diamond cutting disc

can overheat and become damaged as a result. This is

clearly indicated by circular sparking, rotating with the dia-

mond cutting disc.

If this happens, stop cutting and allow the diamond cutting

disc to cool down by running the power tool for a short time

at maximum speed with no load.

Working noticeably slower and with circular sparking indic-

ate that the diamond cutting disc that has become dull. You

can resharpen the disc by briefly cutting into abrasive mater-

ial (e.g. lime-sand brick).

Information on structural design

Slots in load-bearing walls are subject to DIN 1053 part 1 or

country-specific regulations. These regulations must be ob-

served under all circumstances. Seek advice from the re-

sponsible structural engineer, architect or construction su-

pervisor before starting work.

Maintenance and Service

Maintenance and cleaning

u

Pull the plug out of the socket before carrying out any

work on the power tool.

u

To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

u

In extreme conditions, always use a dust extractor if

possible. Blow out ventilation slots frequently and in-

stall a residual current device (RCD) upstream.

When

machining metals, conductive dust can settle inside the

power tool, which can affect its protective insulation.

Store and handle the accessories carefully.

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by

Bosch

or by an

after-sales service centre that is authorised to repair

Bosch

power tools.

After-Sales Service and Application Service

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. You can find explosion drawings and information on

spare parts at:

www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessor-

ies.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the nameplate

of the product.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham Uxbridge

UB 9 5HJ

At www.bosch-pt.co.uk you can order spare parts or arrange

the collection of a product in need of servicing or repair.

Tel. Service: (0344) 7360109

E-Mail: boschservicecentre@bosch.com

You can find further service addresses at:

www.bosch-pt.com/serviceaddresses

Disposal

The power tool, accessories and packaging should be re-

cycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

Only for EU countries:

According to the European Directive 2012/19/EU on Waste

Electrical and Electronic Equipment and its implementation

into national law, power tools that are no longer usable must

be collected separately and disposed of in an environment-

ally friendly manner.

1 609 92A 5WL | (21.08.2020)

Bosch Power Tools