1 695 102 028

2014-10-10

|

Robert Bosch GmbH

Maintenance | TCE 330-TCE 230 | 33

6.

Maintenance

6.1

Suggested lube

Component

Lube

Standard

Pneumatic

ESSO FEBIS K 32

ISO VG 32

Tab. 1:

Lubricants table

!

The manufacturer is not liable for any damage

caused by use of lubes different from those shown in

the table.

6.2

Cleaning and servicing

Before any cleaning or maintenance interven-

tion, disconnect the pneumatic system of the

TCE 330-TCE 230.

To guarantee full efficiency of the TCE 330-TCE 230 and

to ensure functioning without anomalies it is essential

to clean the machine regularly and carry out periodical

maintenance.

Maintenance has to be carried out by the operator

in accordance with the manufacturer's prescriptions

shown here below.

6.3

Maintenance intervals

Maintenance

w

eekl

y

monthl

y

annual

Clean the mechanical moving parts, spray

them with nebulised oil or kerosene.

x

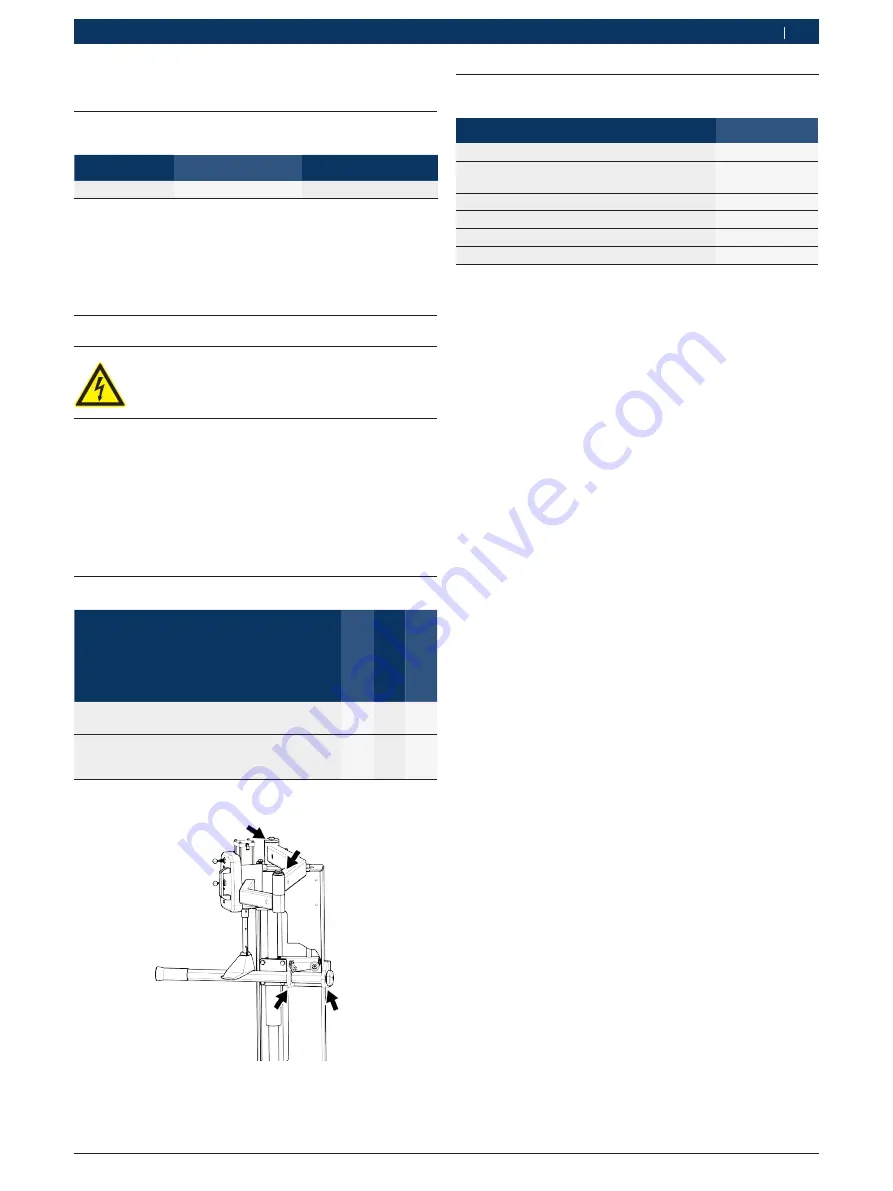

Lube the sliding guides inside the hold-

ing structure (see picture) with appropriate

grease.

x

en

Fig. 19: Parts to be lubricated

6.4

Spare parts and wearing parts

Designation

Order number

Label for mounting arms and mounting heads 1 695 101 274

Label indicating operation of helper and mas-

ter roller

1 695 101 889

Locking/release lever of moving arm

1 695 042 960

Roller

1 695 102 188

Helper actuation valve

1 695 107 075

Master roller actuation valve

1 695 107 075