TRIGGER "ON-OFF" SWITCH

To turn the tool “ON” squeeze the trigger

switch. To turn the tool “OFF”, release the

trigger switch, which is spring loaded and

will return to the “OFF” position

automatically.

To increase switch life, do not turn switch on

and off while tool is under load.

VARIABLE SPEED DIAL

Your tool is equipped with a variable speed

dial. The impact rate (BPM) and rotating

speed (RPM) can be varied according to the

type of work being performed by setting the

variable speed dial to the selected setting.

The chart below will help you to determine

which setting to use for your application.

However, a pre-test will determine the best

speed setting, as the chart is intended only

as a guide. Once the proper setting is

determined the impact rate and rotating

speed is kept constant by means of the

"Electronic Feedback Circuitry". The variable

speed dial can be adjusted while the motor

is running with the tool free from work,

allowing the operator to adjust the impact

rate and rotating speed according to the

actual application.

ELECTRONIC FEEDBACK

CIRCUITRY (EFC)

The internal electronic feedback system

provides a "soft start", which will reduce the

stresses that occur from a high torque start.

The system also helps to keep the pre-

selected impact rate and rotating speed

virtually constant between no-load and load

conditions.

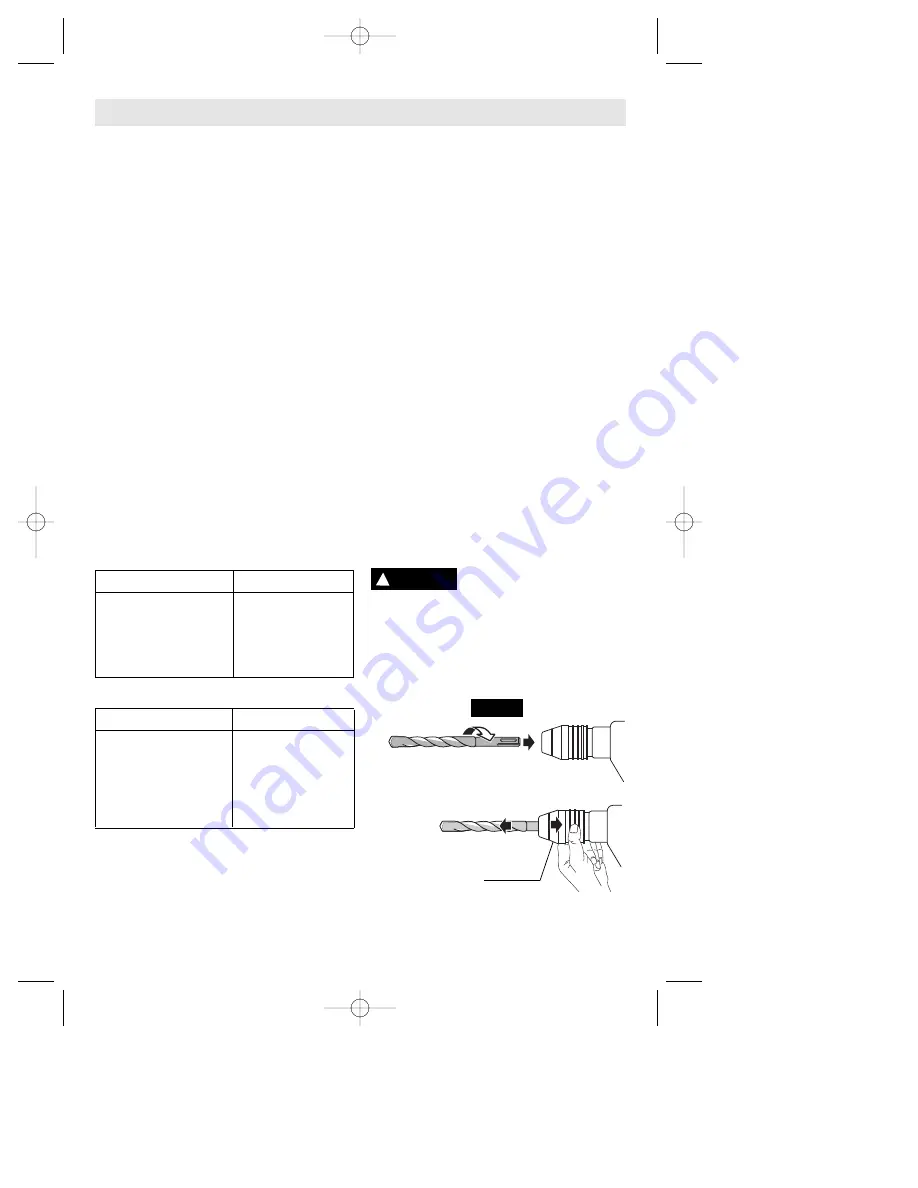

INSTALLING ACCESSORIES

Clean the insert shank end of the accessory

to remove any debris, then lightly grease

with a light oil or lubricant.

Insert accessory into the tool holder through

the dust shield, while twisting and pushing

inward until it locks automatically into place.

Pull outward on the acessory to be certain it

is locked into the tool holder (fig. 2).

NOTE: You may notice some “wobble” or

“run out” of the bit when run in a no load

condition. This is due to the quick change

SDS tool holder assembly. However, once the

bit has a load placed upon it, the bit

automatically centers itself to produce an

accurate hole.

NOTE: The high efficiency available from the

rotary hammers can only be obtained if

sharp and undamaged accessories are used.

The "cost" to maintain sharp and

undamaged accessories is more than offset

by the "time saved" in operating the tool

with sharp accessories.

REMOVING ACCESSORIES

Accessories may be hot

after use. Avoid contact

with skin and use proper protective gloves or

cloth to remove.

To remove an accessory, pull and hold

locking sleeve backward and pull bit

forward. All accessories should be wiped

clean after removing.

Chipping (Demolition)

Area of application

Control setting

Plaster work

1 - 2

Removing tiles

3

Brick work

4

Concrete

5 - 6

Drilling Holes

Lower speeds

Higher speeds

Larger holes

Smaller holes

Accurate starts

Faster penetration

Minimize breakouts

when the bit exits

the material.

-7-

Operating Instructions

!

WARNING

LOCKING SLEEVE

FIG. 2

BM 1619929219 2/03 2/12/03 8:21 AM Page 7