-10-

OPERATING THE TOOL

Following a few simple tips will reduce wear

on the tool and it will reduce the chance of

injury to the operator.

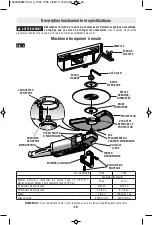

APPLICATIONS

This tool is intended for cutting the following

materials.

1/8˝ maximum thick sheet steel.

Concrete cinder blocks and bricks.

Reinforcing rod-generally under 3/4˝

diameter.

1/8˝ concrete wire mesh.

Corrugated floor and ceiling forms (concrete

forms).

Electrical conduit 1/8˝ wall thickness.

1/8” maximum thick structural forms such as:

channels, angles, plate and etc.

ABRASIVE WHEELS

Use aluminum oxide wheels for cutting metal.

Use silicon carbide wheels for cutting

masonry.

Use dry diamond wheels for cutting concrete.

Dry diamond wheel stay cooler, clogs less

and last longer.

1 Before running a cut-off machine, inspect

the cutting wheel for chips or cracks. Replace

bad wheels immediately. New wheels should

be run in at no load for at least a minute in

direction away from the presence of other

people. Imperfect wheels will normally break

apart during this time.

2. An abrasive cut-off machine must NEVER

be operated without the attached guard

secured in place. The guard should be

rotated into the position where maximum

protection is provided for the operator from

sparks and wheel periphery.

3. Proper apparel for operating the tool

includes eye protection, leather gloves, dust

mask and a shop apron.

4. With the tool in the "OFF" position,

become familiar with handling the tool.

Control the head of the tool with the side

handle. Control the cutting edge of the wheel

with the switch handle. Always use both

hands when operating the tool.

5. Never drop the tool. Set the tool down

gently, but never on the wheel.

6. CUTTING CONCRETE will throw large

amounts of dust into the surrounding

area.

Respiratory protection with minimum N-95

dust masks or respirators are required for the

operator and others in the work area.

7. Due to the size and weight of the cut-off

machine it must not be used be used

overhead or in any position that would not

allow proper control. Ladders or scaffolding

are not considered solid support structures.

8. Avoid overloading tool. Do not allow the

wheel to bind or stall. Many cuts, especially

into solid concrete, require successive

passes. Do not expose any more abrasive

wheel than necessary to cut with normal

amount of pressure applied to tool. Begin

cutting from the edge of the material, starting

with about 1" wheel exposed. Do not force

the tool; load it normally. Depending on

material hardness and density, make

successively deeper passes until cut is

complete.

For dry diamond wheels:

Cutting

masonry / concrete must be done in multiple

passes, scoring the work piece only to the

depth of a segment on each pass. Full depth

of cut in one pass reduces the life of the

body of the blade by thinning it and may

allow the segment to fly away.

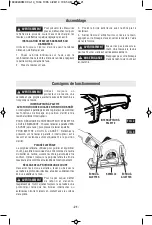

FIRE FORWARD/FIRE REVERSE

Models 1364 & 1365 are shipped with

abrasive Cutoff Machine set up in fire forward

position. Both can be easily converted to fire

reverse position without any additional

accessories.

Fire forward position directs sparks, dust and

debris away from the operator.

Fire reverse position changes direction of

rotation so sparks, dust and debris are

thrown toward the operator.

The proper fire position depends on how the

tool is being held, direction of travel, and

personal preference. Always remember the

reason for this feature is to direct sparks,

dust and debris away from the operator.

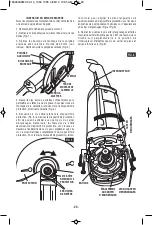

FIRE REVERSE APPLICATIONS

Below are a few examples of when you may

want to change your tool to the reverse fire

position.

• When cutting in a vertical position to direct

debris toward your feet instead of your face.

• When pulling the tool through the workpiece

instead of pushing the tool.

• When working in confined areas close to a

wall.

• Personal comfort.

160992A0MC 04-14_1364 1365 4/28/14 10:35 AM Page 10