-9-

FOOTPLATE ADJUSTMENT

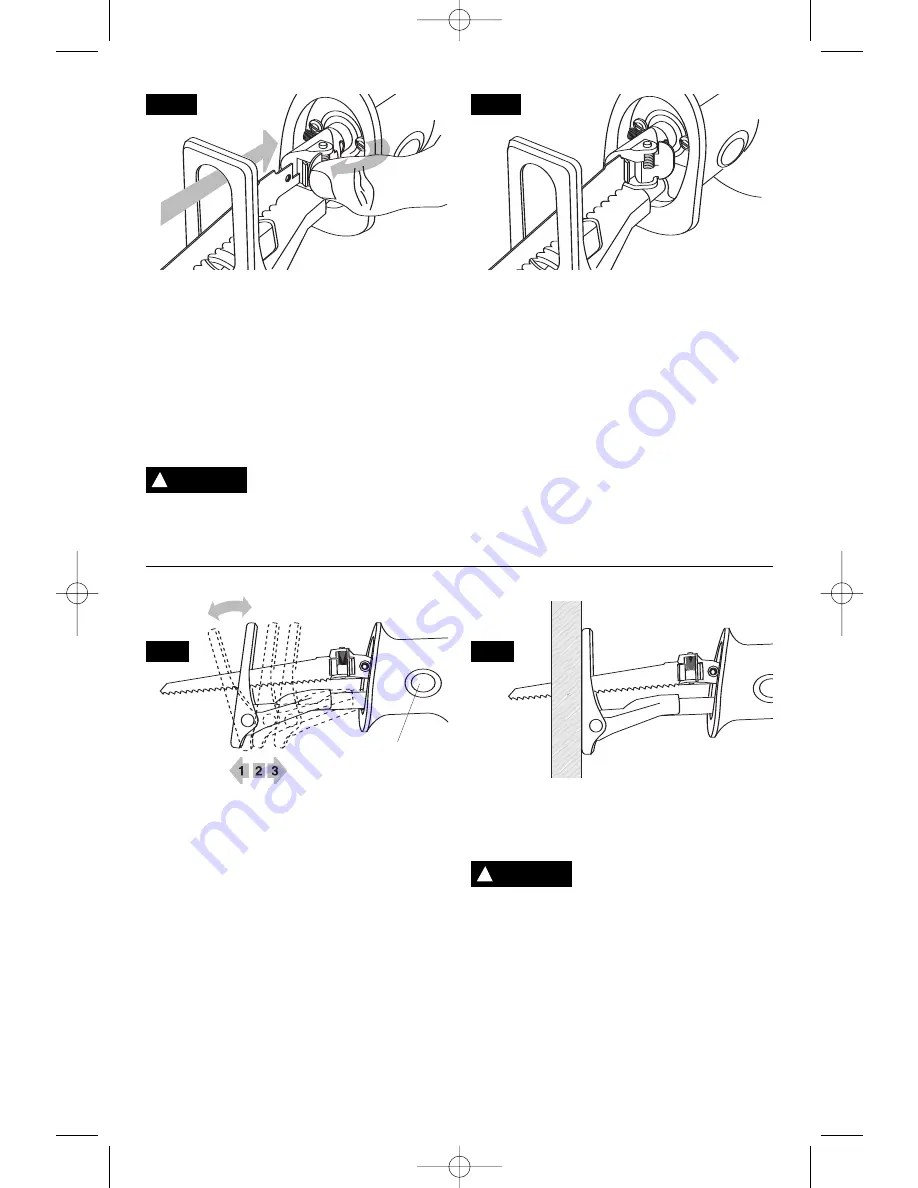

The footplate tilts in order to keep as much of

its surface in contact with the work surface

Fig. 5 (a).

The footplate assembly can also be locked

into one of three projection positions to

optimize blade life and/or to reduce blade

protrusion beyond the end of the footplate,

such as when cutting into large diameter pipe

or into walls. To adjust the footplate position,

simply push the footplate release button and

move the footplate into the desired position.

The locking mechanism is spring-loaded to

lock into one of the 3 positions on the footplate

assembly. If the footplate is pulled out so far

that a notch shows at the other end of the

shaft, the footplate assembly is extended too

far out, and must be retracted to the one of

the 3 positions Fig. 5 (b).

Do not push the footplate

release button while sawing.

It will cause the footplate to release from the

desired settings and you may lose control and

be injured.

To reduce the risk of injury, be sure the blade

extends beyond the footplate and all the way

through the workpiece throughout the stroke.

Blades may shatter if the blade hits the

footplate or hits the work at an angle that is

nearly head-on (Fig. 6).

FIG. 3

FIG. 5

INSTALLING A BLADE

Simply press the release lever forward to open

the tool-less clamp; insert the blade until it

stops and release the lever (Fig. 3). The

spring-loaded mechanism will lock the clamp

against the blade (Fig. 4). Push in and pull out

on the blade to be sure the pin in the clamp

housing goes through the hole in the blade to

hold the blade securely. The blade may be

inserted with the teeth facing down or up.

Make sure that the front end

of the blade extends through

the footplate for the entire stroke length. Do

not use specialty blades that are very short or

those with a significant cant. Blade must not

contact footplate. A blade which is too short or

canted could jam inside the foot and snap.

NOTE:

If you require a basic (Allen wrench)

blade clamp for any reason (extra thick

blades, very thin blades, etc.) an optional

basic blade clamp kit is sold separately. It

contains a clamp, Allen wrench, screw and

lock washer. To use the basic clamp, remove

the tool-less clamp assembly by unscrewing

the setscrew that holds it onto the draw bar.

Then assemble the basic clamp with the

screw and lock washer provided (Fig. 1).

!

WARNING

!

WARNING

FIG. 6

FIG. 4

FOOTPLATE

RELEASE BUTTON

(a)

(b)

BM 2610925947 6-05 6/10/05 10:35 AM Page 9