3 6 |

Bosch Inverter Ducted Packaged Heat Pump

Installation & Operation Manual

03.2019 | BTC 761701105 A

Data subject to change

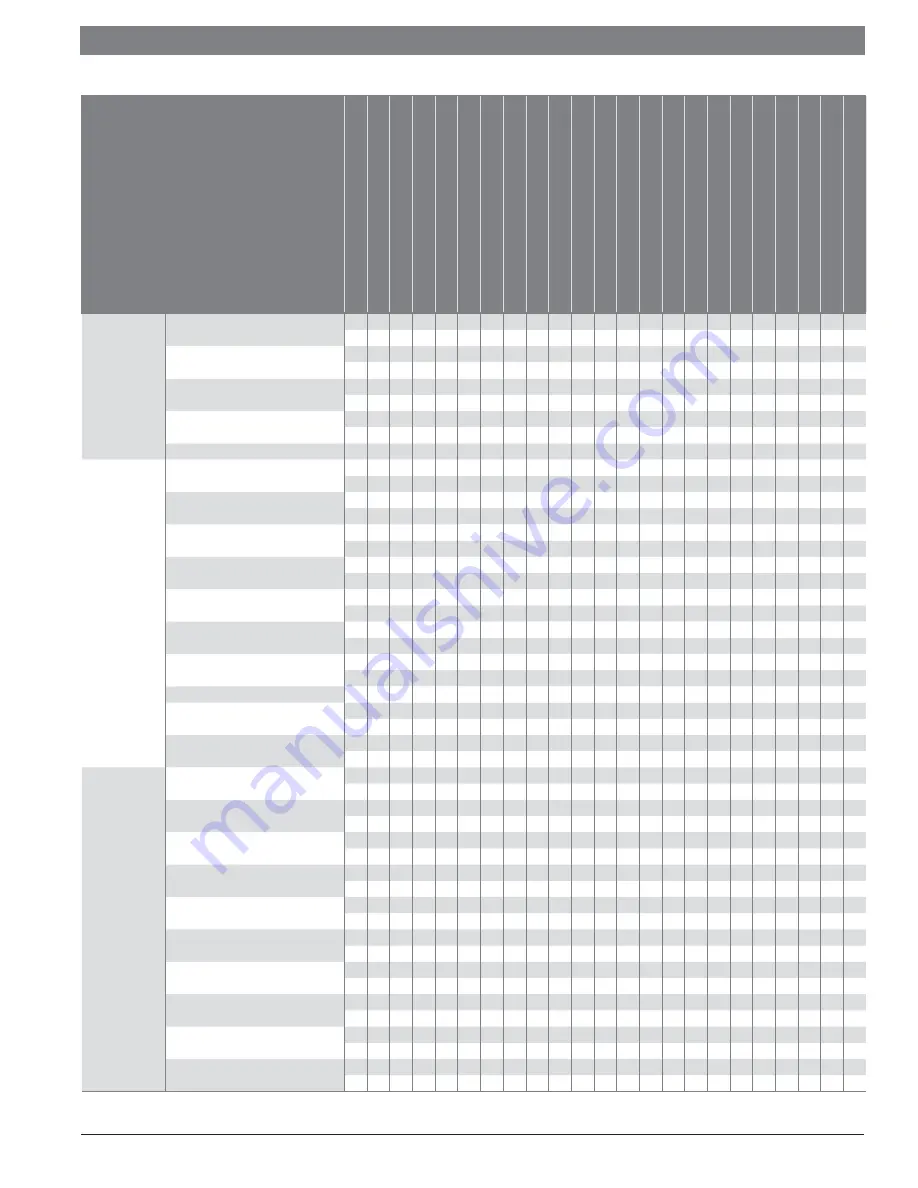

SYSTEM FAULTS

WHA

T T

O

CHECK MODE

PO

WER SUPPL

Y OR HIGH V

O

LT

A

GE WIRINGS

LO

W V

O

LT

A

GE WIRING OR THERMOS

TA

T

I.D.FUSE

INEFFICIENT COMP

.

CONTROL BO

ARD OR WIRES

RES I.D.AIRFL

O

W

RES O.D.AIRFL

O

W

INEFFICIENT O.D.F

AN

RES O.D.RADIA

TO

R

REF

.UNDERCHARGE

REF

.O

VERCHARGE

REF

.CIR.RES

TRICTIONS

EEV OR COIL DEF

.

REV OR COIL DEF

.

REV LEAKING

SER

VICE V

A

LVE LEAKING

PT SENSOR DEF

.

T3 SENSOR DEF

.

T4 SENSOR DEF

.

T5 SENSOR DEF

.

Tf SENSOR DEF

.

HPS SENSOR DEF

.

SYSTEM

Display shows nothing

C

P

S

H

P

S

System won't start

C

P

P

S

S

H

P

P

S

S

Capacity is insuffi cient

C

P

P

P

P

S

S

S

H

P

P

P

P

S

S

S

S

Display is not normal when running

C

P

H

P

Cool when heating requirement

H

P

S

REFRIGERANT

CIRCUIT

P1

C

P

P

S

P

H

P

S

P

P2/H5

C

P

P

S

H

P

P

S

P3

C

P

P

S

P

H

P

S

P

P5

C

P

P

S

S

S

H

S

P0

C

P

P

S

H

P

P

S

P4

C

P

S

H

P

S

S

PH

C

P

S

S

H

P

P

S

C3 (T3 is seated fault)

C

P

S

E7 (T5 is seated fault)

C

S

P

H

S

P

ALT (Ambient temp. beyond the

license)

C

S

H

S

ELECTRICAL

OR

CONTROL

E4

C

P

P

P

P

H

P

P

P

P

H8

C

P

H

P

F1

C

S

P

H

P

E6

C

S

P

H

S

P

P6

C

S

P

H

S

P

P8

C

P

H

P

L0-L9

C

S

P

H

S

P

E9

C

P

H

P

H0

C

P

H

P

E5

C

P

S

H

P

S

Table 29