Maintenance and repair

43/64

3 842 358 792/2016-12, Material and information fl ow technology: HQ 2/C-H, HQ 4,

Bosch Rexroth AG

10.2 Inspection

Conveyor chain

Inspect the conveyor chain regularly, every 1,000 hrs, for ease of movement,

suffi cient lubrication and wear. Inspect more frequently, e.g., every 500 or 200 hrs,

when using production processes that include rinsing, fl uid transfer, etc. in which

the lift transverse unit chain could be washed out.

Lift unit

Regularly check the pneumatic connections for leaks.

10.3 Maintenance

CAUTION

Sudden movements, falling workpiece pallets

Risk of injury caused by sudden movements and falling objects.

Only work on the conveyor chain when the belt section is stationary.

Secure the system against unintended reactivation.

Checking and retensioning the conveyor chain

• Retension the conveyor chain 150 hrs after initial commissioning

(see Section 10.4.4 “Replacing the chain” Fig. 37 on Page 55).

• Retension the conveyor chain every 1,000 hrs (see Section 10.4.4 “Replacing the

chain” Fig. 37 on Page 55).

• Replace the conveyor chain when wear becomes visible, at the latest however

when it has increased in length by 3% (see Section 10.4.4 “Replacing the chain” on

page 51).

Lubricating the conveyor chain

The conveyor chain used in this product comes lubricated.

• Lubricate the conveyor chain before initial commissioning with Structovis GHD

(

0 842 904 229), using 1–2 g oil/m of chain, then every 1,000 hrs with 2–3 g oil/m

of chain.

• Lubricate more frequently, e.g., every 500 or 200 hrs when using production

processes that include rinsing, fl uid transfer, etc. in which the lift transverse unit

chain could be washed out (see Section 10.4.4 “Replacing the chain” on page 51).

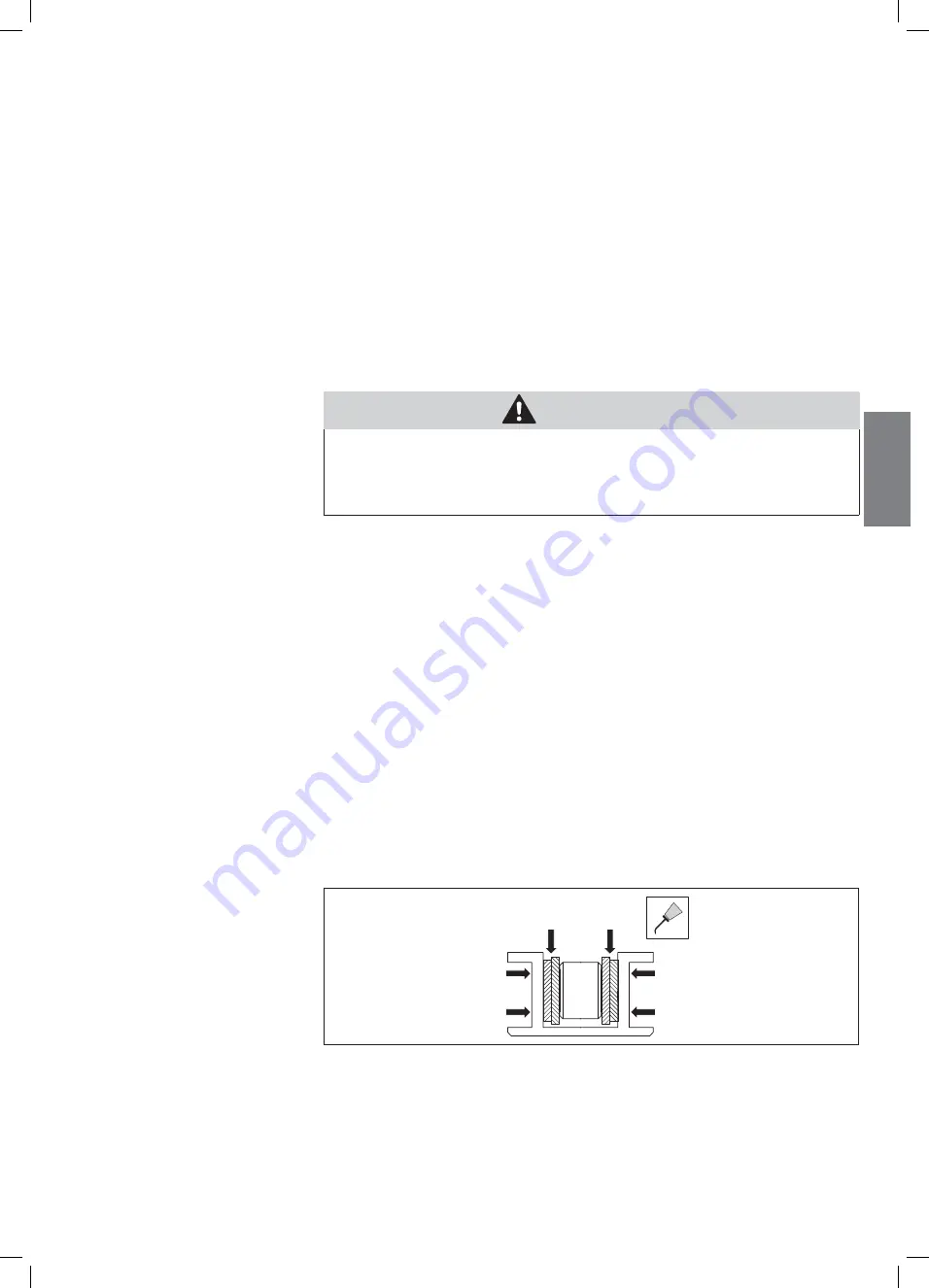

Fig. 24:

*

)

*

)

Lubricating points

*) Also lubricate the sides of

the fl at-top chain belt.

EN

GLISH

551261_2016_12_EN.indd 43

551261_2016_12_EN.indd 43

22.12.2016 10:26:36

22.12.2016 10:26:36