Maintenance and repair

51/64

3 842 358 792/2016-12, Material and information fl ow technology: HQ 2/C-H, HQ 4,

Bosch Rexroth AG

10.4.4

Replacing the chain

NOTE

Conveyor chain failure

Deformations such as bending and/or twisting of the chain, e.g., by tilting the chain

reel during installation, can result in chain failure and even crashing. There is a risk

of damage to property.

Make sure the chain remains straight and can leave the chain reel smoothly

during installation.

Make sure the chain reel cannot tilt during installation.

If the chain reel does tilt during installation and the chain is deformed: Use the

removal tool to remove the affected area, with a generous margin on either end.

NOTE

Travel direction of conveyor chain

Make sure the direction of the travel of the conveyor chain is the same as the main

direction of transport.

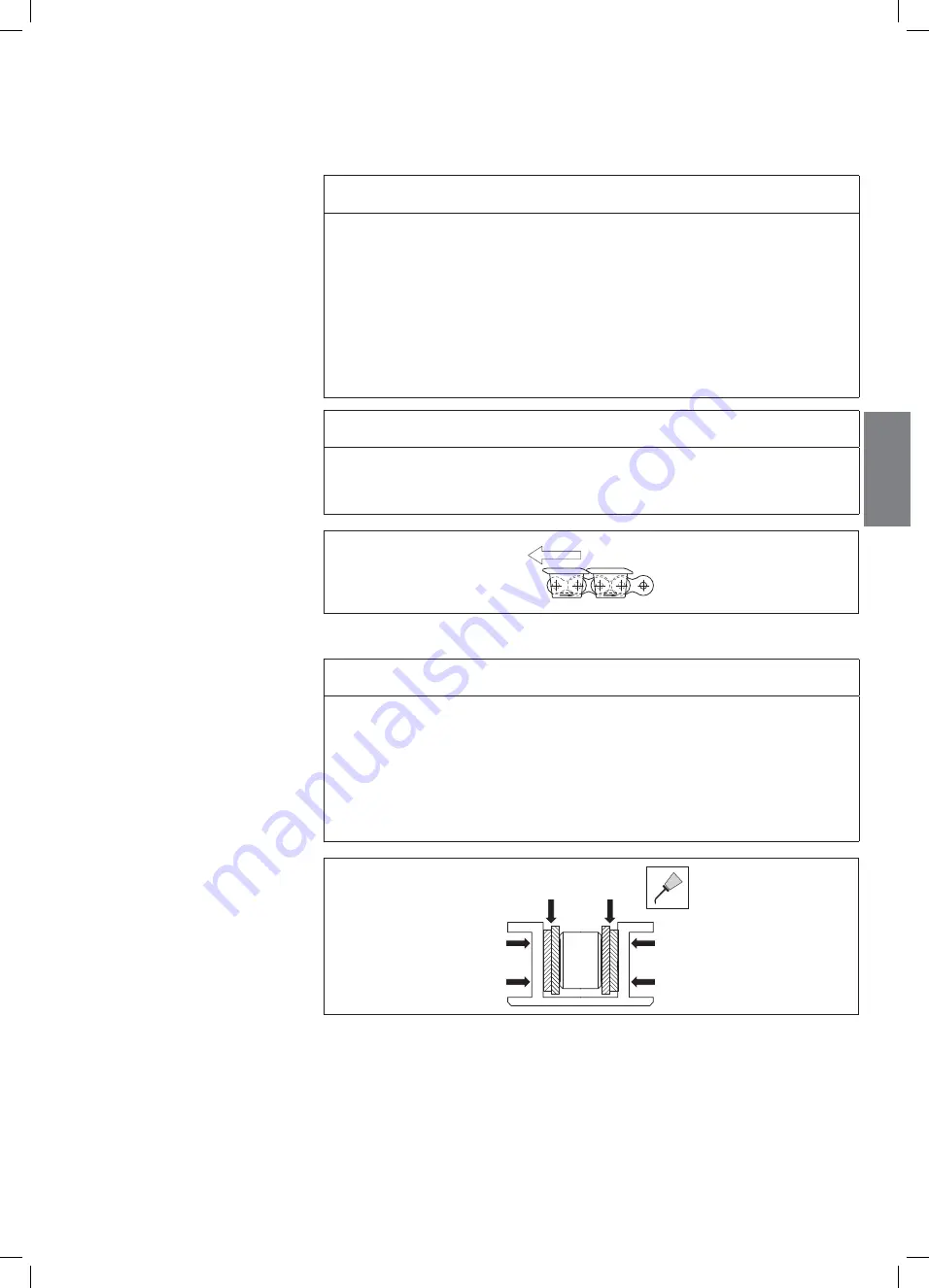

Fig. 32: Travel direction of chain

NOTE

Conveyor chain failure

Inadequate lubrication of the conveyor chain can result in conveyor chain failure or

even crashing. There is a risk of damage to property.

The conveyor chain used in this product comes lubricated.

Lubricate the conveyor chain before initial commissioning with Structovis GHD

(

0 842 904 229), using 1–2 g oil/m of chain, then every 1,000 hrs with

2–3 g oil/m of chain.

Fig. 33:

*

)

*

)

Lubricating points

*) Also lubricate the sides of

the fl at-top chain belt.

EN

GLISH

551261_2016_12_EN.indd 51

551261_2016_12_EN.indd 51

22.12.2016 10:26:36

22.12.2016 10:26:36