Maintenance and Repair

39/76

3 842 358 724/2013-04, MIT: BS 2/C-… + BS 2/R-…,

Bosch Rexroth AG

10.3.4

Conveyor chain (fl at top chain/accumulation roller chain)

The conveyor chain used in this product has already been lubricated at the factory

before delivery.

Before commissioning for the fi rst time, lubricate the conveyor chain with 1 to 2 g

oil per chain meter, and afterwards every 1000 operating hours with 2 to 3 g oil/m,

using Structovis GHD (

0 842 904 229).

For system-related reasons, the lubricant can spread.

*

)

*

)

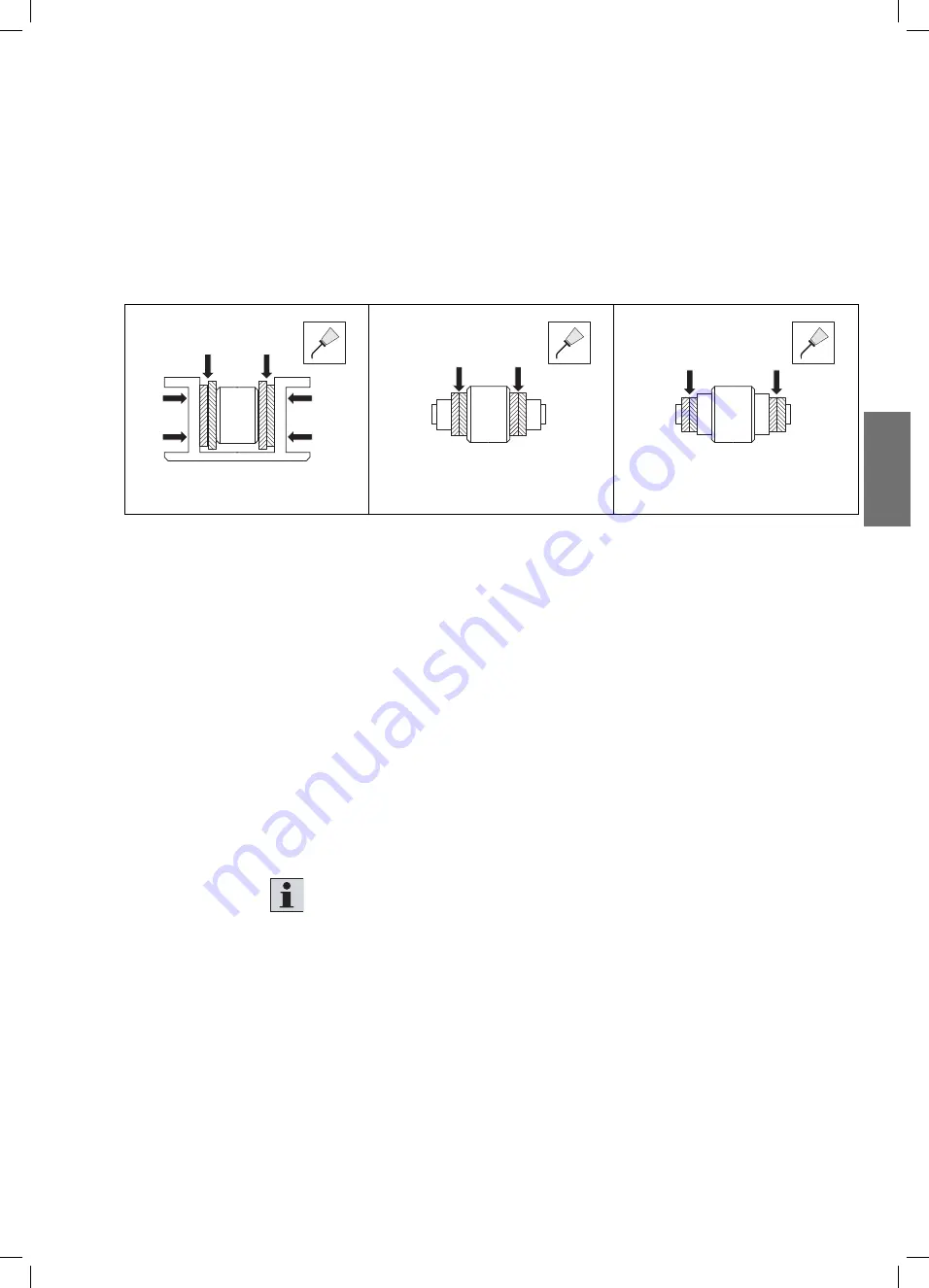

Flat top chains

Accumulation roller chain

Vplus accumulation roller chain

Fig. 18: Lubrication points

*) Also lubricate the fl at top chain on the side (in curves and sections).

NOTE!

Always comply with the maintenance intervals, as a lack of lubrication will result

in operational disruptions due to a chain malfunction, up to a system crash with

substantial damage to property.

Maintain a maintenance schedule.

The running times during set-up and commissioning of the system count as a part

of the fi rst maintenance interval.

If you do not know how long the system ran during set-up and commissioning,

lubricate the conveyor chain before starting production.

Lubricate the chain after downtimes > 6 months (e.g. if set-up took a very long

time or if the system was temporarily decommissioned).

Before lubricating the chain, clean off any excess grease, dirt, or other

contamination. While doing so, also check the conveyor chain for wear and

elongation.

We recommend: The LU 2 automatic lubrication unit enables an optimally

defi ned, uniform lubrication of the conveyor chain during operation.

See page 41.

EN

GLISH

358724_2013_04_EN.indd 39

358724_2013_04_EN.indd 39

27.05.2013 13:08:02

27.05.2013 13:08:02