Installation 29/68

RE 93100-01-B/2019-09-10, A20V(L)O Series 1,

Bosch Rexroth AG

▶

When designing the reservoir, ensure that there is an adequate distance between

the suction line and the drain line. This prevents the heated return flow from

being drawn directly back into the suction line.

▶

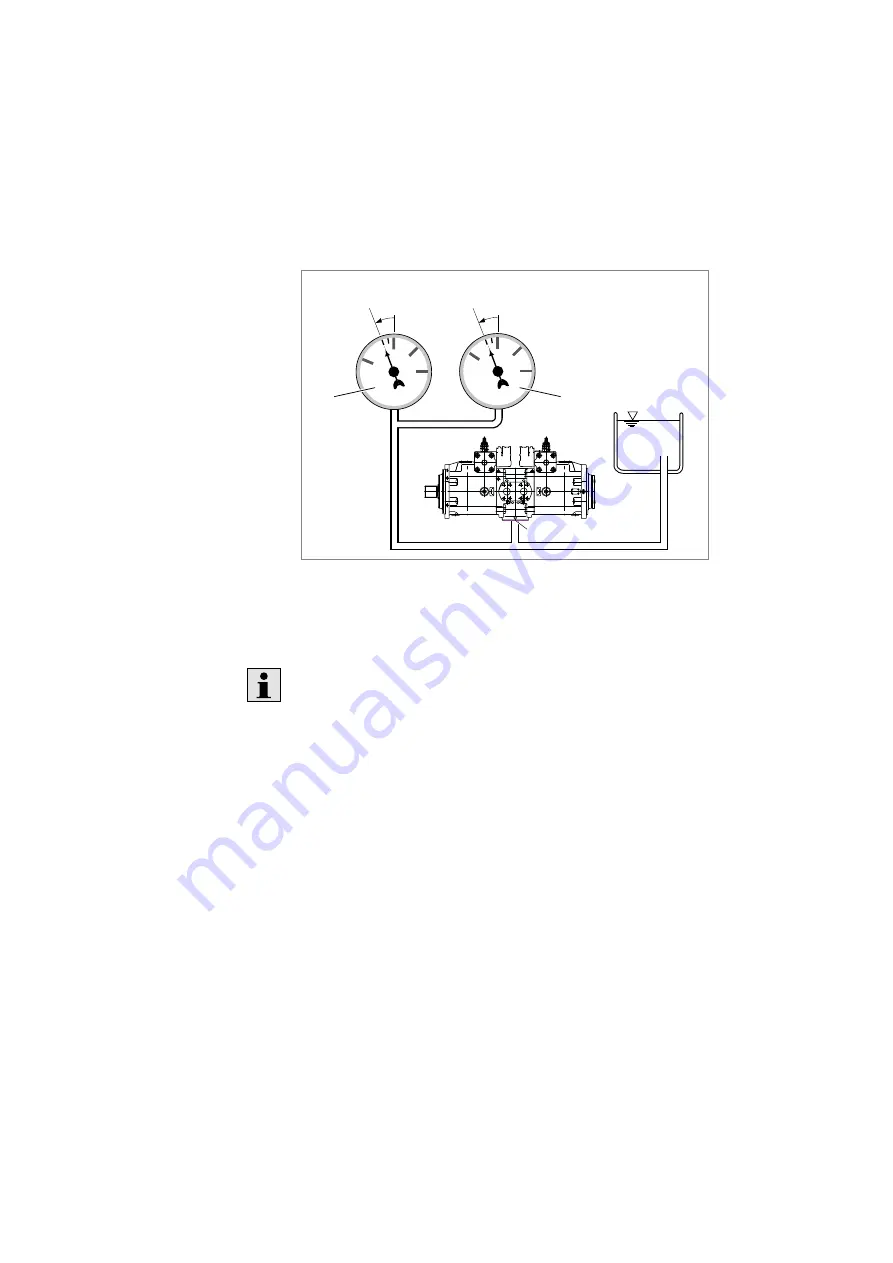

Make sure that a minimum suction pressure of 0.8 bar abs.

(without charge pump) and/or 0.6 bar abs. (with charge pump) is present

at port

S

during operation, in all installation positions and installation locations

for the axial piston pump, see Fig. 8. For additional pressure levels see.

-0.2

0.8 abs.

1 2

3

0

0 1

2

-1

2

1

S

Fig. 8: Suction pressure

1

Absolute pressure gauge

2

Standard pressure gauge (relative)

The suction conditions improve with below- and inside-reservoir installation.

▶

Make sure that the working environment at the installation site is completely

free of dust and foreign substances. The axial piston unit should be clean

when installed. Contamination of the hydraulic fluid can considerably affect

the function and service life of the axial piston unit.

▶

Use fiber-free cleaning cloths for cleaning.

▶

Use suitable, mild cleaning agents to remove lubricants and other heavy

contamination. Do not allow cleaning agents to enter into the hydraulic system.

7.3 Installation position

The axial piston unit can be installed in the following positions. The pipeline routing

shown illustrates the basic layout.