Transport and storage 29/68

RE 92003-01-B/12.2015, A4VG Series 32,

Bosch Rexroth AG

▶

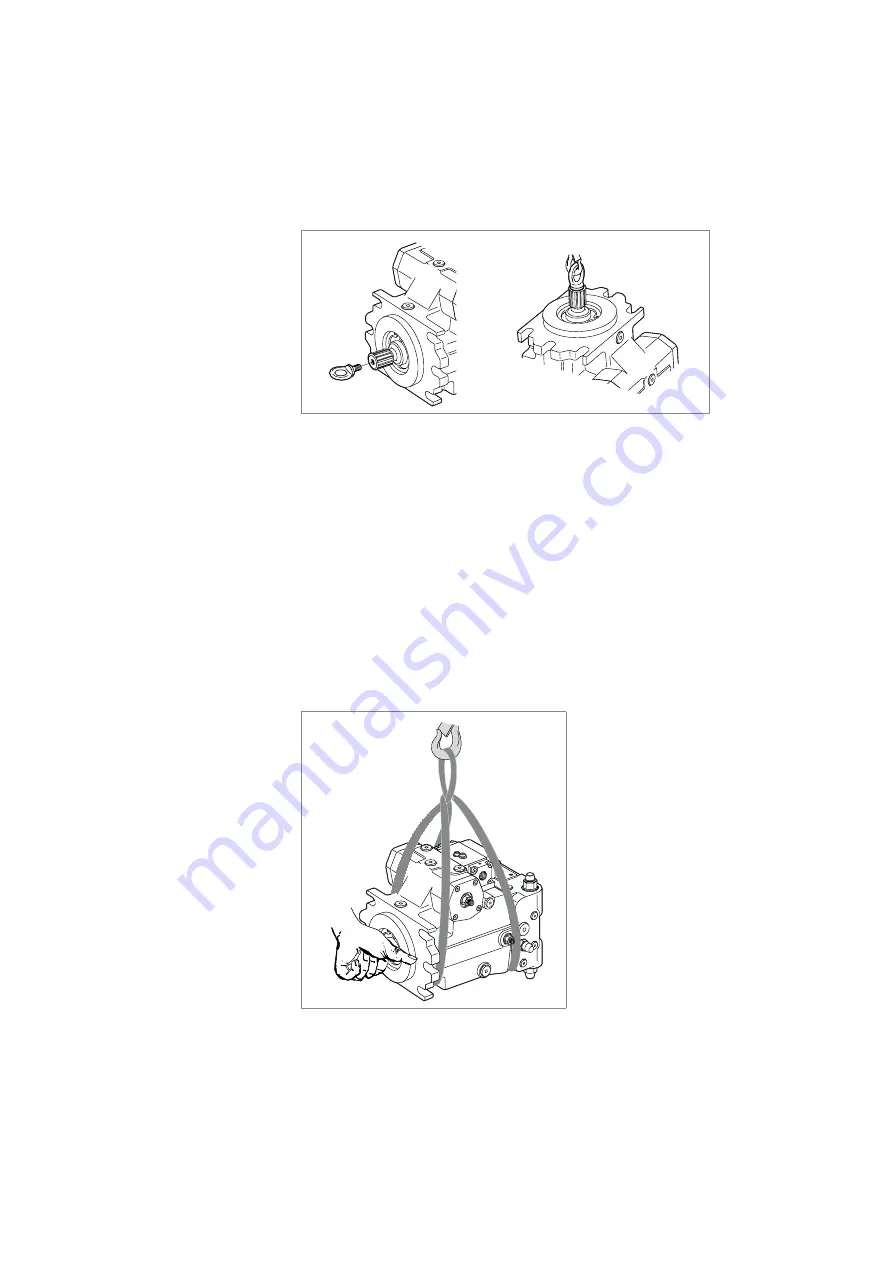

To do this, screw an eye bolt completely into the female thread on the drive shaft.

The thread size is stated in the installation drawing.

▶

Make sure that the eye bolt can bear the total weight of the axial piston unit plus 20%.

You can hoist the axial piston unit as shown in Fig. 7 with the eye bolt screwed into

the drive shaft.

Fig. 7: Fixing the eye bolt

wARnInG

Danger from suspended loads.

During transport with a lifting device, the axial piston unit can slip out of the lifting

strap and result in injury.

▶

Use the widest possible lifting strap.

▶

Make sure that the axial piston unit is securely fixed with the lifting strap.

▶

Only guide the axial piston unit by hand for fine positioning and to avoid oscillations.

▶

Never stand or put your hands under a suspended load.

▶

Place the lifting strap around the axial piston unit in such a way that it does not

pass over attachments (e.g., valves, piping) and that the axial piston unit is not

suspended from attachments (see Fig. 8).

Fig. 8: Transport with lifting strap

Transport with lifting strap