42/68 Installation

Bosch Rexroth AG

, A4VG Series 32, RE 92003-01-B/12.2015

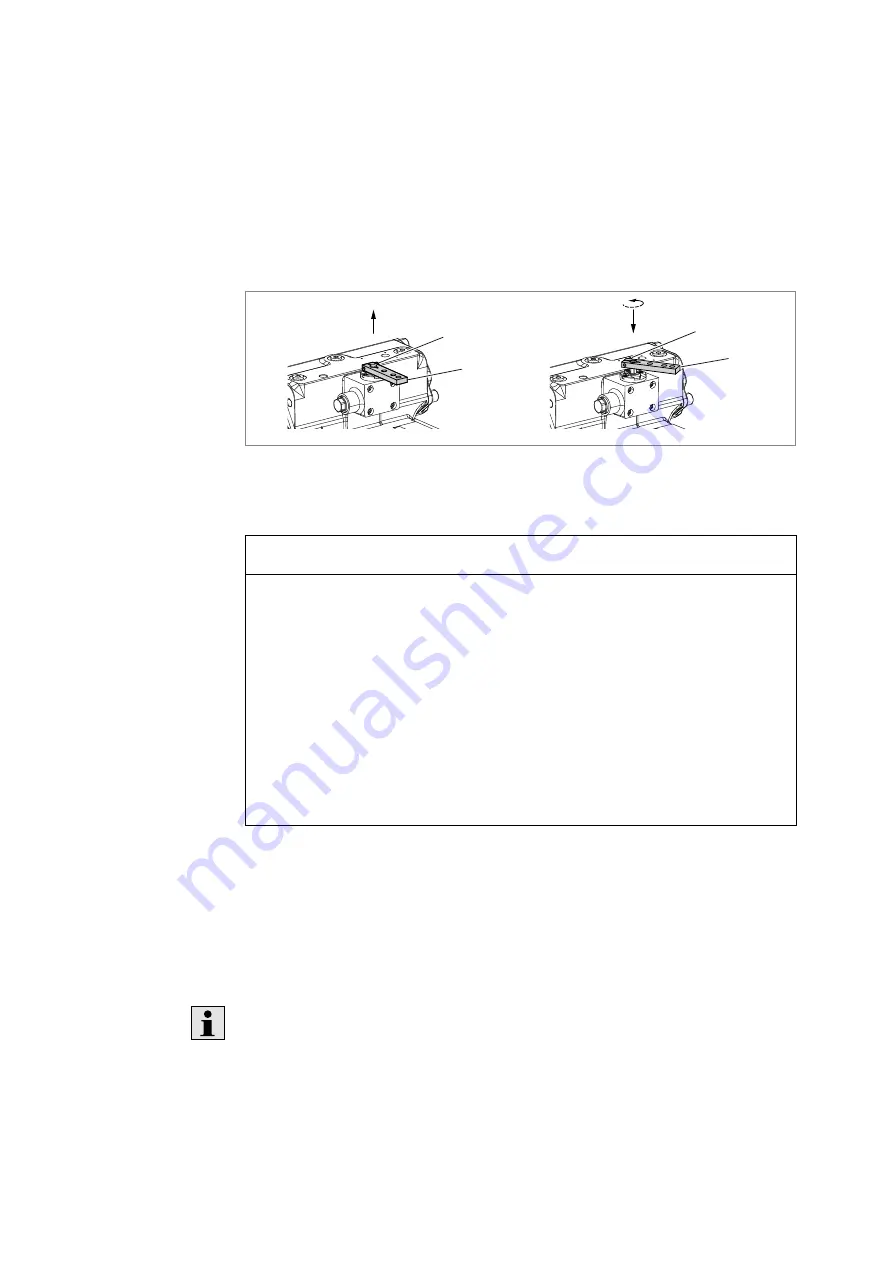

7.4.7 Changing the lever position of the Hw control

If necessary, you can change the position of the lever by turning.

•

Hexagon socket wrench with WAF 10 mm

1.

Loosen and remove the mounting bolts (1) of the HW lever (2).

2.

Pull the HW lever up, turn it into the desired position and push it back down.

3.

Tighten the mounting bolt (1) again.

Tightening torque

M

A

= 6.5 Nm.

1

2

1

2

Fig. 14: Changing the lever position of the Hw control

7.4.8 Hydraulically connecting the axial piston unit

NOTICE

Insufficient suction pressure!

Generally, a minimum permissible suction pressure at port “

S

” is specified for axial

piston pumps in all installation positions. If the pressure at port “

S

” drops below

the specified values, damage may occur which may lead to the axial piston pump

being damaged beyond repair!

▶

Make sure that the necessary suction pressure is not undercut. This is

influenced by:

– the piping (e.g. suction cross-section, pipe diameter, length of suction line)

– the position of the reservoir

– the viscosity of the hydraulic fluid

– a filter cartridge or check valve in the suction line, if these are fitted (regularly

check the level of soiling of the filter cartridge)

The machine/system manufacturer is responsible for dimensioning the lines. The

axial piston unit must be connected to the rest of the hydraulic system in accordance

with the hydraulic circuit diagram of the machine/system manufacturer.

The ports and fastening threads are designed for the maximum pressure specified in

the data sheet. The machine/system manufacturer must ensure that the connecting

elements and lines correspond to the specified application conditions (pressure,

flow, hydraulic fluid, temperature) with the necessary safety factors.

Connect only hydraulic lines that are appropriate for the axial piston unit port

(pressure level, size, system of units).

Required tools

Procedure