Robert Bosch GmbH

en

15

ACS 500

1 689 975 197 (2006-09-22)

9.

Repairs

Warning - Danger of frostbite

During repair work on the ACS 500 refrigerant

in liquid or gaseous form can escape and cause

frostbite to the body.

Close valves on refrigerant flask.

Wear protective goggles.

Wear gloves.

9.1

Opening and closing the ACS 500

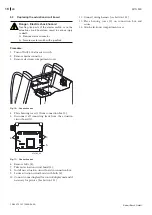

9.1.1 Electronic compartment

H P

LP

V

R134a

Kg/g

min/s

mbar

459786/12

1

1

2

3

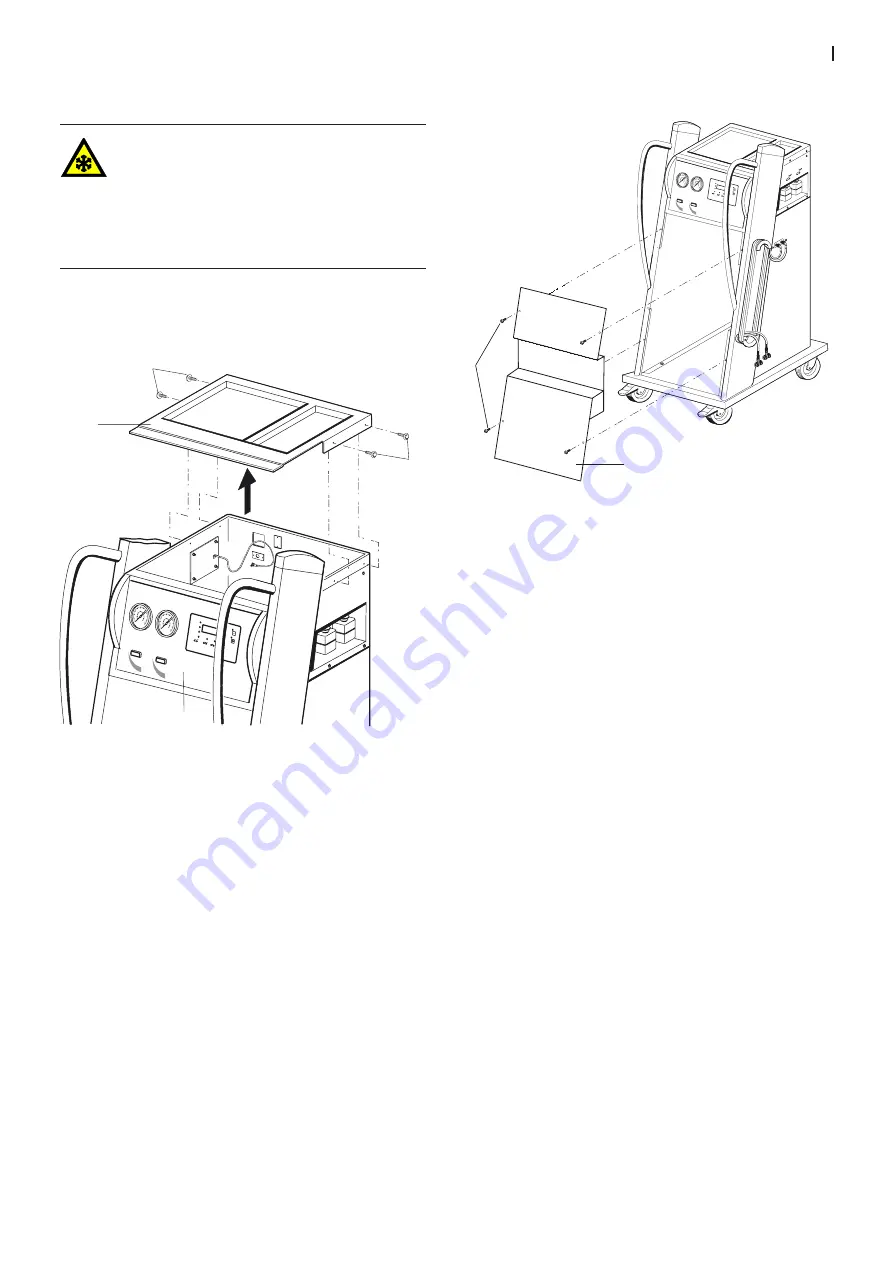

Fig. 8:

Electronic compartment

Opening the electronic compartment:

1. Remove four self-tapping screws (1).

2. Replace cover (2) backwards and lift upwards.

Closing the electronic compartment:

1. Replace cover (2) and slide forwards underneath the

control panel (3).

2. Secure cover with four self-tapping screws (1).

e

e

e

9.1. Cold chamber

HP

LP

459

779-

13

BOSCH

ACS 40

0

2

1

Kg/g

min/s

R134a

V

Fig. 9:

Cold chamber

Opening the cold chamber:

1. Remove hexagon socket screws (2).

2. Slide on front cover (1).

Closing the cold chamber:

1. Slide on front cover (1).

2. Secure front cover with four hexagon socket

screws (2).