6 720 608 032

Maintenance and service

17

5

Maintenance and service

5.1

Maintenance intervals

The GWH 1600 H

requires periodic maintenance. The

below time maintenance intervals should keep the unit

operating for many years.

Every year

B

Inspect inlet water filter screen ( 5.2)

B

Inspect pilot assembly and flame ( 5.3)

B

Inspect burner assembly ( 5.4)

Every 2 years

B

Lubricate and clean water valve ( 5.2)

Every 3 to 5 years

B

Rebuild water valve ( 5.2)

B

Clean pilot assembly and clean or replace orifice

( 5.3)

5.2

Water valve

The water valve is the main control that tells the heater

to fire. If the periodic maintenance is neglected, more

costly damage may occur over time.

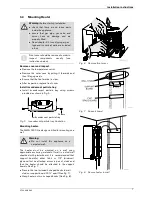

Inspecting inlet water filter screen

Shut off the installer supplied cold water isolation valve

to the heater. If one is not installed, install before

proceeding. Open the nearest hot water tap to drain the

plumbing lines. Position a bucket under the heater's

water valve assembly to catch any water that may drain

from the heater. Remove the filter retaining clip located

at base of water valve (see Fig. 23). Remove the

threaded bushing to access the cylindrical filter inside.

Remove filter, clean with water and inspect for damage.

If the filter is at all damaged, it should be replaced.

Lubricating the water valve

A more detailed instruction is available on our website

at www.boschhotwater.com. Shut off the installer

supplied cold water isolation valve to the heater. If one

is not installed, install before proceeding. Open the

nearest hot water tap to drain the plumbing lines.

Position a bucket under the heater's water valve

assembly to catch any water that may drain from the

heater. Disconnect the inlet water pipe going to the

back of the water valve. Disconnect the water pipe

leading out of water valve to the heat exchanger. Do this

by removing the retaining clip on water valve assembly

and pulling the pipe free from the water valve. Loosen

the two set screws at the bottom of the water valve

where it connects to the gas valve. If the set screws are

seized, STOP and call Bosch tech support before

proceeding. Forcing and snapping seized set screws

may cause irrevocable damage to the water valve and

gas valve assemblies. Remove the water valve by

pulling it to the right. Separate the two halves of the

water valve by removing the five screws on the left side

of the water valve. Apply lithium or faucet & valve grease

to the pushrod and o-ring. (See Fig. 25, num. 23).

Inspect the venturi and clean if necessary. (see Fig 27,

num. 23).

Rebuilding the water valve

Several parts within the water valve should be replaced

every 3 to 5 years depending on water quality and

usage. The parts list and instructions can be found on

our website at www.boschhotwater.com. Failure to

rebuild the water valve can result in decreased

performance or damage to the heater.

5.3

Pilot

Inspecting pilot

The pilot should burn with a clean sharp blue flame. The

flame should fully engulf the tip of the thermocouple. If

it does not, clean the pilot assembly per procedure

below.

Cleaning pilot assembly

Shut off gas supply to the heater using installer supplied

manual gas shutoff. Locate pilot gas tubing mounted in

the center of the burner assembly. At the base of the

pilot gas tubing there is a retaining clip. Release pilot

gas tubing from this clip. Push upwards on other end of

pilot gas tubing to release it from burner mount.

Remove brass hex headed pilot orifice from gas valve

(located near base of pilot gas tubing). Soak orifice and

pilot gas tubing in carburetor cleaner for 30 minutes.

Dry off and reinsert orifice in gas valve. If heater is an LP

unit, replace orifice. Reinstall the pilot gas tubing

following removal instructions in reverse. Open gas

supply and return heater to service.

Warning:

Failure

to

perform

recommended maintenance may result

in complete failure of the unit over time.

The warranty does not cover failures

due to improper or insufficient

maintenance.

Caution:

Do not ream or poke orifice as

it will enlarge orifice opening.