Commissioning

17

AWE – 6721835317 (2021/09)

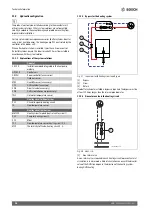

6.2

Adjusting the operating pressure of the heating

system

Table 8 Operating pressure

▶ Top up to 1.5–2.0 bar unless otherwise specified.

▶ If the pressure does not remain constant, check whether the heating

system has any leaks and if the capacity of the expansion vessel for

the heating system is sufficient.

6.3

Operation without heat pump (individual operation)

The indoor unit can be put into operation without a connected heat

pump, for example, if the heat pump is installed at a later date. This is

termed individual operation or stand-alone operation.

In individual operation, the indoor unit only uses the auxiliary heater for

heating and DHW heating.

If the indoor unit and the heating system are to be filled before the heat

pump is connected, connect the inlet and outlet of the heat transfer

medium to/from the heat pump to ensure circulation.

▶ Open any shut-off valves that are installed in the heat transfer

medium circuit.

Commissioning in individual operation:

▶ In the

Heat pump

service menu, select the option

Operation

without heat pump

(

control unit manual).

6.4

Function test

The compressor is preheated before starting. This can take up to

2 hours, depending on the outdoor temperature. The prerequisite for

starting is that the value recorded by the temperature sensor of the

compressor (TR1) is 10 K higher than the temperature sensor at the

supply air terminal device (TL2). The temperatures are displayed in the

diagnosis menu of the control unit.

▶ Test active components of the system.

▶ Check whether the start condition for the heat pump has been

satisfied.

▶ Check if there is a heating or hot water demand.

-or-

▶ Draw off DHW or increase the heating curve to generate demand (

instructions for control unit).

▶ Check whether the heat pump starts.

▶ Make sure that no alarms are currently active.

-or-

▶ Troubleshooting.

▶ Check the operating temperatures (

instructions for the control

unit).

6.4.1

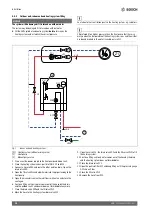

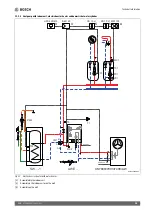

Pressure switch and overheating protection

The pressure switch and overheating protection are connected in series.

Alarms or information triggered at the control unit indicate either that

the operating pressure is too low, or that the temperature of the electric

booster heater is too high.

NOTICE

Material damage from running dry!

When the heating pump PC0 is operated for a long time when the

operating pressure is too low, it can be damaged.

▶ Eliminate any leaks in the system that are indicated when the

pressure switch is triggered.

The triggering of the pressure switch only blocks the electric booster

heater. The heating pump PC0 and the heat pump can continue to run if

there is a risk of frost.

Pressure switch

The indoor unit has a pressure switch which triggers once the pressure in

the heating system falls below 0.5 bar. Once the pressure exceeds

0.5 bar, the pressure switch is automatically reset.

▶ Make sure that the expansion vessel and pressure relief valve are

configured for the indicated operating pressure.

▶ Check for any leaks.

▶ Slowly increase the pressure in the heating system by adding water

through the fill valve.

Overheating protection (OHP)

The overheating protection triggers when the temperature of the electric

booster heater rises above 95 °C.

▶ Make sure that the particle filter is not blocked and that the flow

through the heat pump and heating system is unimpeded.

▶ Check the operating pressure.

▶ Check the heating and DHW settings.

▶ Reset the overheating protection. To do this, press the button on the

bottom of the terminal box.

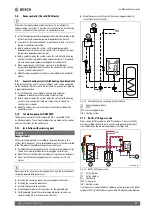

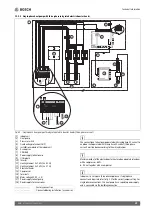

6.4.2

Operating temperatures

The operating temperature check must be performed in heating mode

(not in DHW or cooling mode).

For optimum system operation, the flow rate in the heat pump and

heating system must be monitored. This check should be performed

after 10 minutes heat pump operating time and during high compressor

heating output.

The temperature differential for the heat pump must be set for the

different heating systems.

▶ With underfloor heating system: set a temperature difference of 5 K.

▶ With radiators: set a temperature difference of 8 K.

These settings are optimal for the heat pump.

Check the temperature differential at high compressor heating output:

▶ Open the diagnosis menu.

▶ Select Monitored values.

▶ Select Heat pump.

▶ Select Temperatures.

▶ Read the primary flow temperature (heat transfer medium off, sensor

TC3) and return temperature (heat transfer medium on, sensor TC0)

in heating mode. The flow temperature must be higher than the

return temperature.

Display on the pressure gauge

1 bar

Minimum charge pressure. When the system is cold, the

operating pressure must be kept at roughly 0.2–0.5 bar

above the pre-charge pressure of the nitrogen cushion in

the expansion vessel. The pre-charge pressure is 0.7–

1.0 bar as a rule.

3 bar

Maximum charging pressure at maximum heating water

temperature: must not be exceeded (the pressure relief

valve will open).