8 |

Bosch Buderus SSB800SA | SSB1000SA | SSB1000TL Boilers Control Operations Guide

01.2020 | Bosch Thermotechnology Corp.

Data subject to change

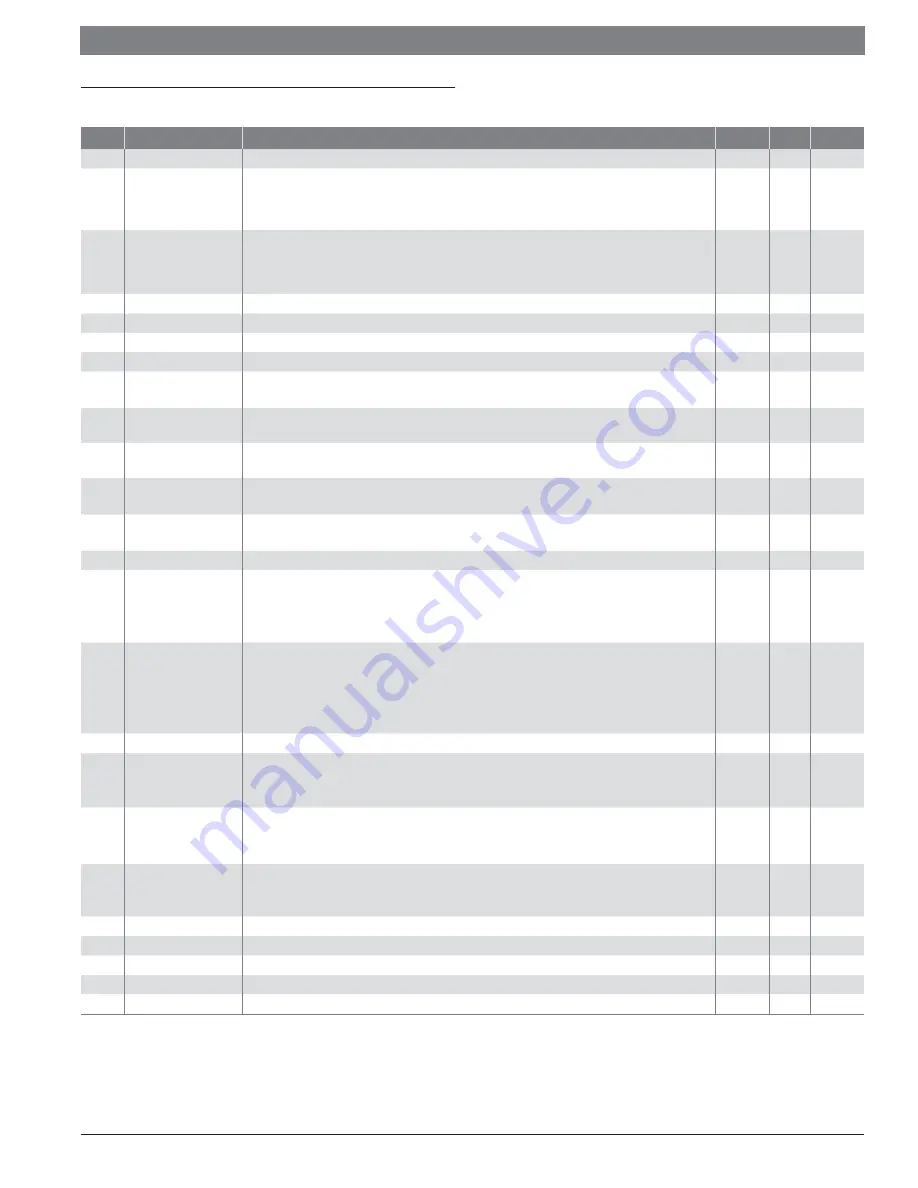

4 Boiler Cascade Settings

Number

Parameter Name

Description

Default

Min

Max

73

Boiler Address

Set boiler address i.e. Stand-Alone, Managing, Dependent 1....7

MANAGING

0

16

156

Permit Emergency Mode

Enable

Emergency Mode

in a multiple boiler cascade installation to ensure that any dependent boiler can operate

independently should communication with the managing boiler be interrupted or the managing boiler loses

communication with the supply sensor. The boiler will operate at a predetermined

Emergency Setpoint

which is

set using Parameter #157.

YES

NO YES

157

Emergency Setpoint

Emergency Setpoint

is the

fi

xed set point which a boiler will operate at within a cascade installation if that boiler

has lost communication with the Managing boiler or the Managing boiler loses communication with the supply

sensor. Parameter #156 must be “Yes” on each dependent boiler and

Emergency Setpoint

set for the desired

Emergency Temperature at which the boiler is to operate.

158 °F

68 °F

194 °F

158

Delay Per Start Next Blr

See

Hyst Down Start Boiler

.

1275 sec.

0 sec.

1275 sec.

159

Delay Per Stop Next Blr

See

Hyst Up Stop Boiler

.

1275 sec.

0 sec.

1275 sec.

160

Delay Quick Start Next

See

Hyst Down Quick Start

.

400 sec.

0 sec.

1275 sec.

161

Delay Quick Stop Next

See

Hyst Up Quick Stop

.

240 sec.

0 sec.

1275 sec.

162

Hyst Down Start Boiler

If the system temperature is

Hyst Down Start Boiler

degrees below the system set point the boilers are started at

intervals of

Delay Per Start Next Blr

.

9 °F

0 °F

72 °F

163

Hyst Up Stop Boiler

If the system temperature is

Hyst Up Stop Boiler

degrees above the system set poin tthe boilers are stopped at

intervals of

Delay Per Start Next Blr

.

3.6 °F

0 °F

72 °F

164

Hyst Down Quick Start

If the system temperature is

Hyst Down Quick Start

degrees below the system set point the boilers are started at

intervals of

Delay Quick Start Next

.

18 °F

0 °F

72 °F

165

Hyst Up Quick Stop

If the system temperature

Hysteresis Up Quick Stop

degrees is above the system set point the boilers are stopped

at intervals of

Delay Quick Stop Next

.

7.2 °F

0 °F

72 °F

166

Hyst Up Stop All

If the system temperature is

Hyst Up Quick Stop

degrees above the system set point the boilers are stopped at

intervals of

Delay Quick Stop Next

.

14.4 °F

0 °F

108 °F

167

Number Of Boilers

The amount of boilers in the cascade.

1

1

8

168

Power Mode

Power mode 0: Power control disabled, each boiler modulates based on the system setpoint.

Power mode 1: Power control algorithm to have a minimum amount of boilers active.

Power mode 2: Power control algorithm to have a maximum amount of boilers active.

Power mode 3: Power control algorithm to have a balanced amount of boilers active.

2

0

3

169

Max Setp Offset Down

In order to achieve the desired Target System Supply Temperature during a call for heat the boilers may need to

operate at temperatures greater than or less than the desired Target System Supply Temperature. The operating

range in which the boilers are allowed to adjust the individual boiler supply temperatures is de

fi

ned by the

Max Setp

Offset Down

and

Max Setp Offset Up

(parameter #170) values. Each dependent boiler will display a “Calculated

Setpoint” temperature on the display which will be within this Off set Range either above or below the overall Target

System Supply Temperature.

0 °F

0 °F

72 °F

170

Max Setp Offset Up

See Parameter #169 for explanation of

Max Setp Offset Down

and

Max Setp Offset Up

.

36 °F

0 °F

72 °F

171

Start Mod Delay Fact

The Managing boiler will calculate the difference between the System Target Setpoint and the measured System

Supply Temperature once a period of time equal to

Delay Period Start Next Boiler

x

Start Modulation Delay

Factor

has passed.

20

0

255

172

Next Boiler Start Rate

The percentage of power a boiler must reach before the Managing boiler will begin the process of bringing on the

next boiler within the cascade. See Parameter#158 for further information on the amount of time which must pass

at this power percentage before the next boiler in the cascade rotation is enabled.

80%

10%

100%

173

Next Boiler Stop Rate

The percentage of power a boiler must reach before the Managing boiler will begin the process of turning off the last

boiler enabled within the cascade rotation sequence. See Parameter #159 for further information on the amount of

time which must pass at this power percentage before a boiler is turned off.

25%

10%

100%

174

Boiler Rotation Interval

Number of days selectable.

5 DAYS

0 DAYS

30 DAYS

175

First Boiler To Start

First boiler in cascade that will start.

1

1

8

180

Pwr Mode 2 Min Power

Minimum average burner power setting.

20%

0%

100%

181

Pwr Mode 2 Hysteresis

Hysteresis for the minimum average boiler power setting.

40%

0%

100%

182

Post-Pump Period

Factory setting - Do Not Change

N/A

N/A

N/A

Table 3