26

en | Starting up

Display Unit DDU 7

04.02.2019 | V 02 |

Manual

Bosch Motorsport

5.

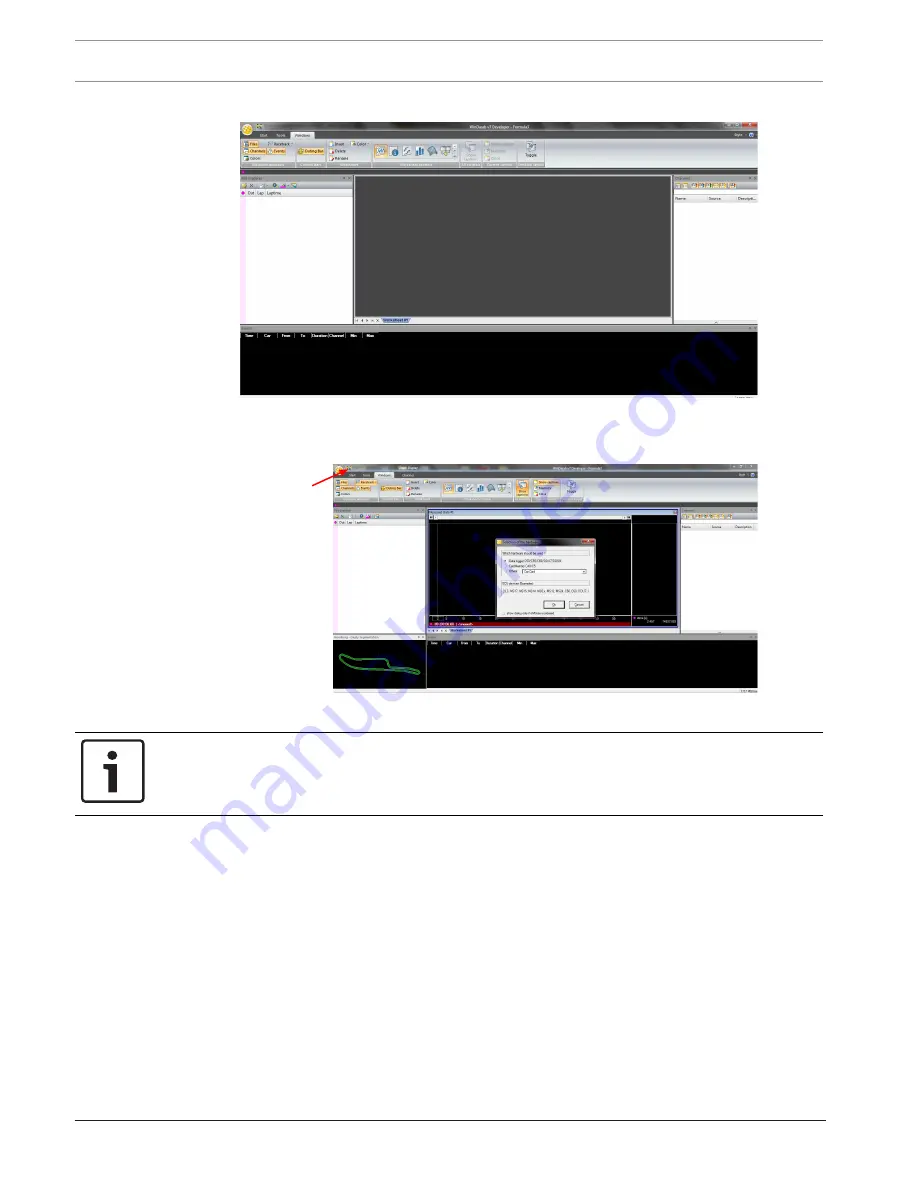

Start the WinDarab software.

6.

Disconnect the DDU 7 network cable.

7.

Click on the ‘Read Data from Logging Device’ icon.

8.

Choose your logger and click ‘OK’ when done.

Click

'read data from

logging device'

The ‘Data Logger Import’ dialog opens.

Notice!

Refer to the WinDarab V7 manual for instructions on how to use the ‘Data Logger Import’

dialog and for more detailed descriptions and instructions.

9.

Choose the device and the IP address for the device.

10. Click ‘Apply changes’ when done.

Summary of Contents for DDU 7

Page 1: ...Display Unit DDU 7 Manual V 02 2 4 2019 ...

Page 2: ......

Page 139: ...Display Unit DDU 7 Firmware en 139 Bosch Motorsport Manual 04 02 2019 V 02 ...

Page 155: ......