General information

en

13

K

General information

General information

Checking the wall

■

The wall must be level, vertical and adequately load-

bearing.

■

The depth of the bore holes must be the same

length as the screws. The wall plugs must have a

secure grip.

■

The enclosed screws and wall plugs are suitable for

solid brickwork. Suitable fasteners must be used for

other structures (e.g. plasterboard, porous concrete,

poroton bricks).

■

The maximum weight of the extractor hood is

40 kg

.

Electrical connection

:

Warning – Risk of electric shock!

Components inside the appliance may have sharp

edges. These may damage the connecting cable. Do

not kink or pinch the connecting cable during

installation.

The required connection information can be found on

the rating plate on the top of the appliance.

Length of the cable: approx. 1.30 m

This appliance complies with the EC interference

suppression regulations.

:

Warning – Risk of electric shock!

It must always be possible to disconnect the appliance

from the power supply. The appliance must only be

connected to a protective contact socket that has been

correctly installed. If the plug can no longer be reached

after installation, an energy-isolating device in the

phases must be provided in the permanent electrical

installation in accordance with the installation

regulations. The permanent electrical installation must

only be wired by a professional electrician. We

recommend installing a residual-current circuit breaker

(RCCB) in the appliance's power supply circuit.

5

Installation

Installation

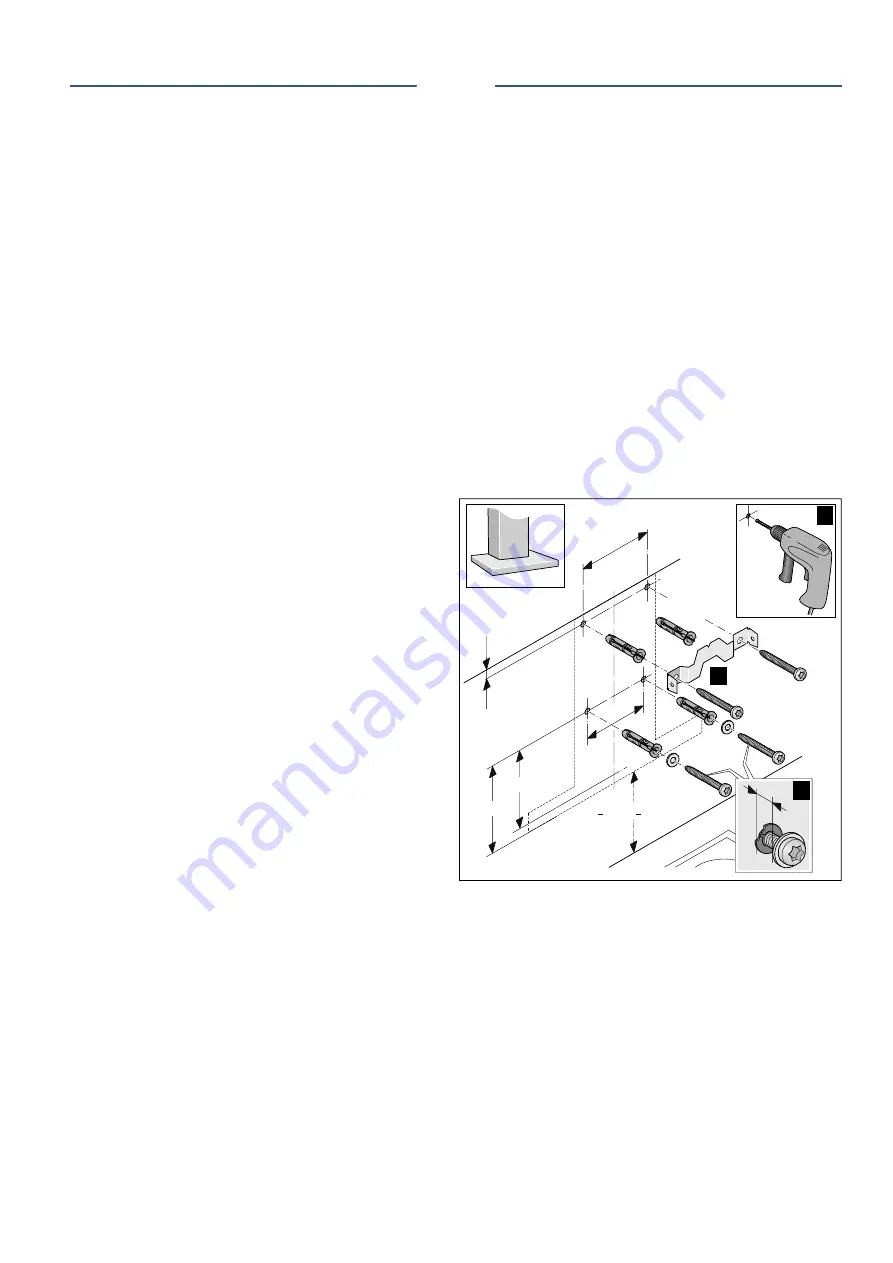

Preparing the installation

Caution!

Ensure that there are no electric wires, gas or water

pipes in the area where holes are to be made.

Caution!

Holes must be drilled differently depending on how the

appliance is designed. Before installing the extractor

hood, take note of its design.

1.

Mark a vertical centre line on the wall from the

ceiling to the lower edge of the extractor hood.

2.

Mark positions for the screws and the contour of the

attachment area.

3.

Drill 8mm Ø holes to a depth of 80mm and press

the wall plugs flush with the wall.

¨

4.

Screw on the fixing bracket for the flue duct.

©

5.

Screw in 2 securing screws with washers to

approx.5mm.

ª

[

!

!

$

%

&