3:2

Note: Fault codes are not a foolproof system. Never assume that a part has failed based on a displayed fault code.

)RU

example

if the control

module is displaying F30 (open sensor), the failure could be caused by a loose connection or faulty wire harness between the control module and

sensor

or the sensor could simply be unplugged.

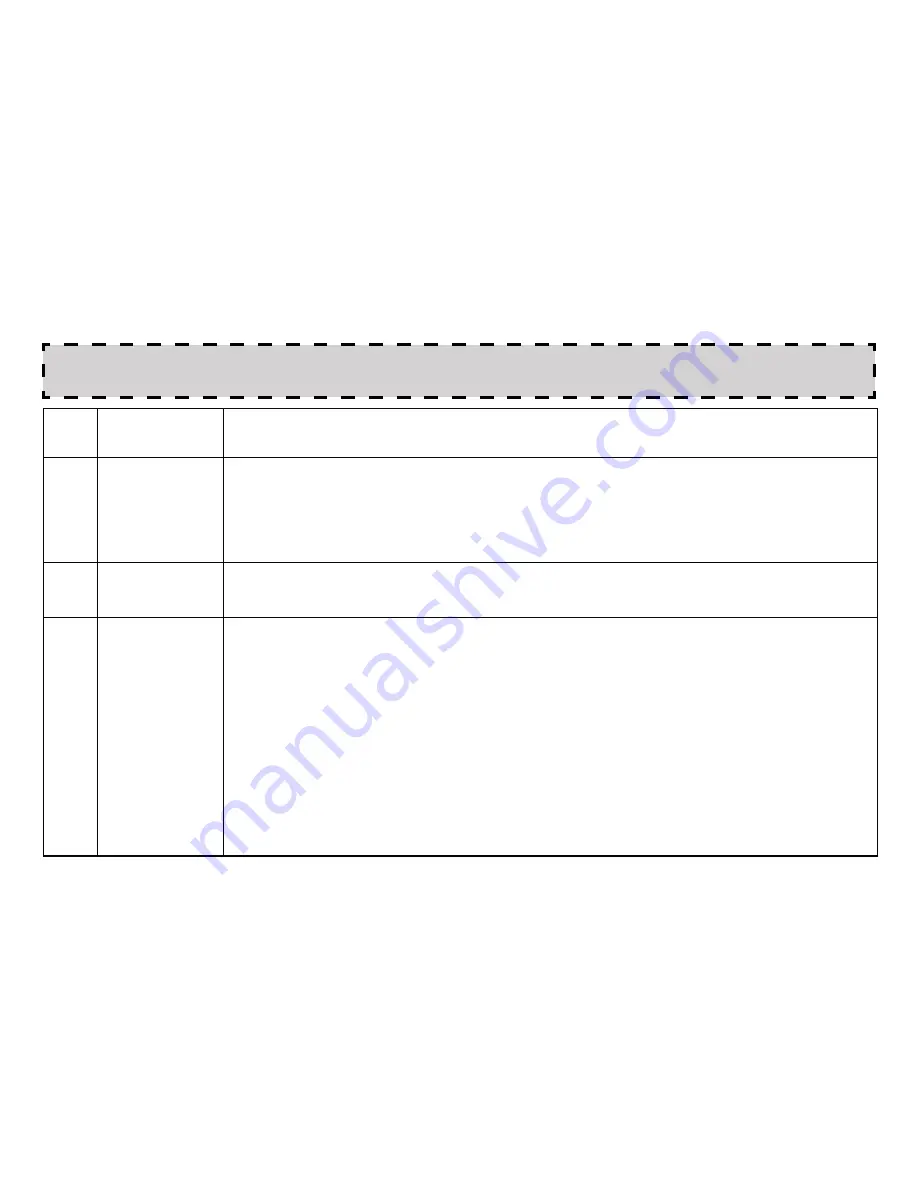

FAULT

CODE

LIKELY FAILURE

CONDITION/

CAUSE

SUGGESTED CORRECTIVE ACTION

F10

F11

F12

F13

Runaway Temperature

Shorted Keypad

Bad Micro Identification

Bad EEPROM Identifica-

tion/Checksum error

1. (F10 only) Check oven temp

ensor

!

robe & harness. Replace if necessary. If oven is overheating, disconnect power. If oven continues

to overheat when the power is reapplied, replace control module. Severe overheating may require the entire oven to be replaced should

damage be extensive.

2. (F11, 12 & 13) Disconnect power, wait 30 seconds and reapply power.

3. (F11, 12 & 13) If fault returns upon power-up, replace control module.

F30

F31

Open probe connection

Shorted Probe connec-

tion

1. (F30 or F31) Check resistance at room temperature & compare to

RTD Sensor Resistance

chart. If resistance does not match the RTD

chart

replace RTD

ensor

!

robe. Check

ensor wiring harness between control module &

ensor

!

robe connector.

2. (F30 or F31) Check resistance at room temperature

0

if less than 500 ohms, replace RTD

ensor

!

robe. Check for shorted

ensor

!

robe

harness between control module &

!

robe connector.

F90

F91

F92

F93

F94

Maximum oven door

unlock time exceeded

Maximum oven door

unlock attempts ex-

ceeded

Maximum oven door

open time exceeded

Maximum oven door lock

time exceeded

Maximum oven door lock

attempts exceeded

If lock motor runs:

1. Test continuity of wiring between control module and lock switch on lock motor assy. Repair if needed.

2. Advance motor until cam depresses the plunger on lock motor switch. Test continuity of switch contacts. If

! !

lock motor assy.

3. If motor runs

and switch contacts and wiring harness test good, replace the control module

#

If lock motor does not run:

1

. Test continuity of lock motor windings. Replace lock motor assy if windings are open.

2. Test lock motor operation by using a test cord to apply voltage. If motor does not operate

replace lock motor

5#

3. If motor runs with test cord

check continuity of wire harness to lock motor terminals. If harness is good

! "#

Fault Codes From Tech Sheet