66

en | Installation of the Pipe System

FCS-320-TM Aspirating Smoke Detector

F.01U.130.928 | 1.0 | 2009.11

Operation Guide

Bosch Sicherheitssysteme GmbH

5

Installation of the Pipe System

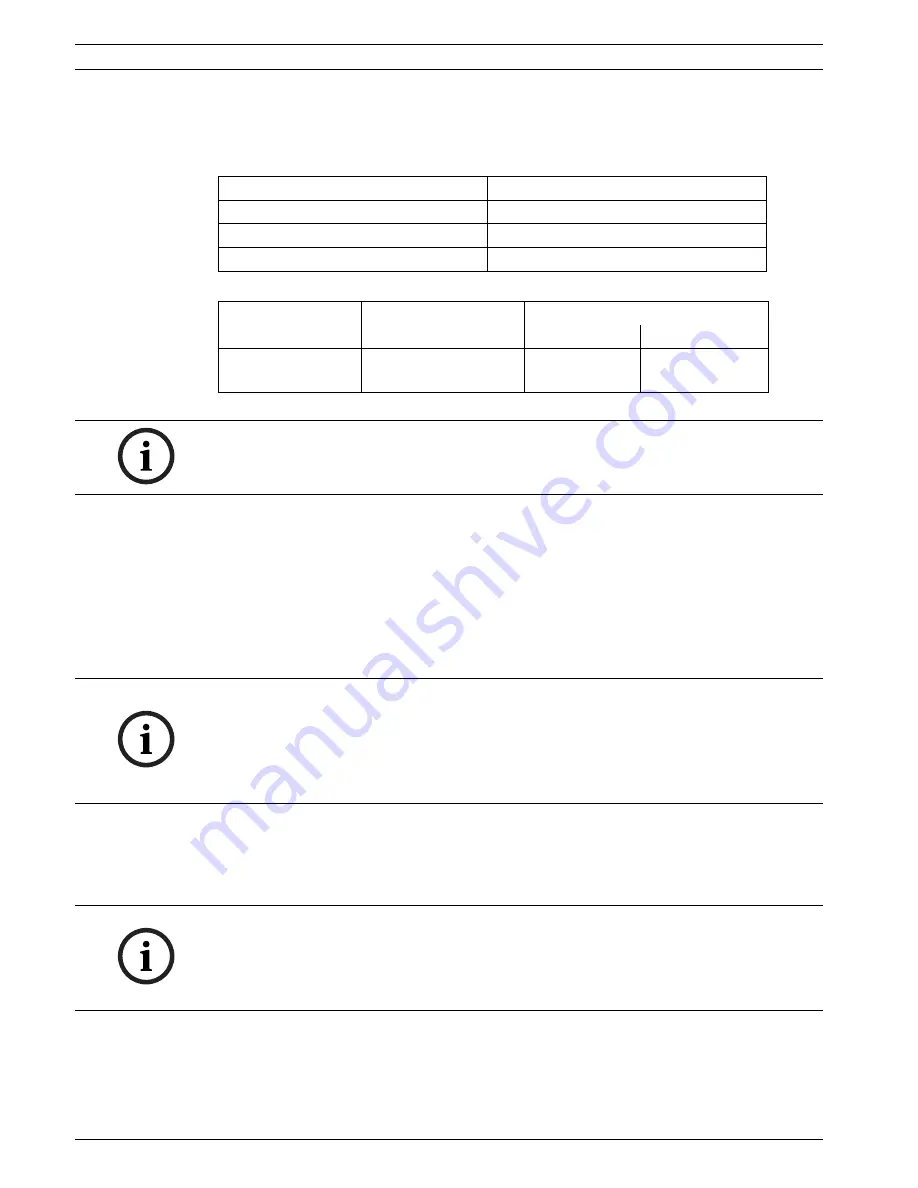

At the very least, the pipes and fittings used for the pipe system must comply with class 1131

according to EN 61386-1, 2004. Class 1131 requires the following of the pipe system in use:

The pipe system must be constructed using the following pipes and the associated fittings:

* PVC pipes do not correspond to the temperature range given above.

Installation instructions

The pipe system must be constructed according to planning specifications and taking into

account the planning guidelines (see

Section 3 Planning, page 31

).

1.

Shorten the pipes with a pipe-cutter (38 mm) or a metal saw. Deburr the joints and clean

up the chips.

2.

Before gluing, clean the adhesion points with the prescribed cleaning agent (Tangit) to

remove dirt and grease. Use the Tangit adhesive to glue the pipe transitions with the

appropriate fittings so that they are airtight.

3.

Minimize pipe lengths and changes of direction. Pipe elbows have an extremely high flow

resistance. Therefore, they should only be used where they cannot be avoided for

structural engineering reasons. If necessary, reduce pipe lengths in proportion to the

pipe elbows used.

4.

Fix the pipe system. It must not sag or be possible to move it. Fasten the pipes with pipe

clips without rubber inserts. The distance between the pipe clips should not exceed

80 cm. At high temperatures, reduce the distance between the pipe clips to a maximum

of 30 cm.

Features

Severity

Compression resistance

125 N

Shock resistance

0.5 kg, drop height of 100 mm

Temperature range

-15 °C to +60 °C

Exterior diameter

Internal diameter

ABS

PVC*

Smoke aspiration

pipe

25 mm

21.4 mm

21.2 mm

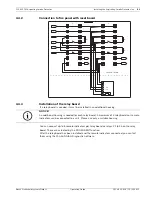

NOTICE!

When constructing the pipe system, observe the temperature range specified in

Section 2.8.2 Pipe System, page 29

.

NOTICE!

If halogen-free plastics must be used, the installation procedures may vary depending on the

selected material:

–

ABS is glued

–

Polypropylene (PP) is welded

–

Polyamide (PA) is pushed together and bolted.

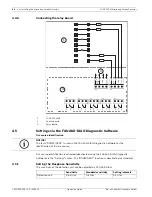

NOTICE!

Pipe bends must be given preference over pipe elbows. Too many bends and pipe elbows

reduce the air speed in the aspiration pipe, thereby increasing the detection time.

As a benchmark, a pipe bend corresponds to a straight pipe length of 0.3 m. An elbow

corresponds to a straight pipe length of 1.5 m.

Summary of Contents for FCS-320-TM

Page 1: ...FCS 320 TM Aspirating Smoke Detector FCS 320 TM FCS 320 TM R en Operation Guide ...

Page 2: ......

Page 99: ......