14

Model RT Energy Recovery Unit

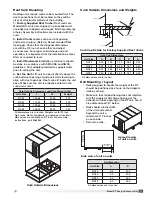

The method of compressing and restraining the motor

/ blower assembly varies with each product. If sheet

metal screws or bolts are used, they are installed with

an equal number on both the front and the rear of

each assembly. Screws or bolts used on the rear rail

of the assembly are difficult to see. It is recommended

that the rear screws or bolts be removed prior to the

front ones in order to reduce the chance of injury. If

restraining bands are used instead of screws or bolts,

carefully cut and remove the bands.

Upon receipt, visually inspect motor / blower

assemblies to verify presence of spring isolation

devices. If they are present, carefully remove shipping

restraints to allow free movement of assembly.

NOTE

Many motor / blower assemblies include optional

spring vibration isolation devices. When these

isolation springs are used, the motor / blower

assembly is secured for shipment by compressing

the springs and securing the assembly to

intermediate rails (see photo).

CAUTION

These assemblies are shipped with the springs in

a compressed state and when shipping restraints

are removed, the assembly will bounce upward.

Do not position hands or fingers where they may

be pinched or injured by sudden movement of the

assembly.

Motor / Blower Assembly

in shipping position

Spring Isolation

Device

Vibration Isolators

Any lifting lug that is located as shown should be

removed in order to permit installation of the P trap

drain kit.

NOTE

On some models of the RT, one lifting lug may be

positioned directly in front of the condensate drain

connection. See illustration.

1 Fan

Wheel

Dia.

1 Fan

Wheel

Dia.

Rota

tio

n

Rota

tio

n

R

ot

ation

R

ot

ation

Length of Straight Duct

GOOD

POOR

GOOD

POOR

GOOD

POOR

Turning

Vanes

Turning

Vanes

SYSTEM EFFECT FACTOR CURVES

FPM X 100

OUTLET VELOCITY

0 5 10 15 20 25 30 35 40 45

1.2

1.0

0.8

0.6

0.4

0.2

0.0

S

TA

TIC PRESSURE LOSS

CUR

VE

1

CUR

VE

2

CUR

VE

3

CUR

VE 4

Recommended Discharge Duct Size and Length

Model

Blower

Size

Duct Size Straight Duct Length

RT-20

9

14 x 14

36

RT-45

10

20 x 20

36

RT-55

12

20 x 20

36

RT-90

15

28 x 28

60

All dimensions shown in inches.

• Recommended duct sizes are based on velocities across the

cfm range of each model at approximately 800 feet per minute

(FPM) at minimum airflow and up to 1600 fpm at maximum

airflow. Recommended duct sizes are only intended to be a

guide and may not satisfy the requirements of the project.

Refer to plans for appropriate job specific duct size and/or

velocity limitations.

• Straight duct lengths were calculated based on 100% effective

duct length requirements as prescribed in AMCA Publication

201. Calculated values have been rounded up to nearest foot.

Ductwork Connections

Examples of poor and good fan-to-duct connections

are shown below. Airflow out of the fan

should be directed straight or curve

the same direction as

the fan wheel rotates.

Poor duct installation

will result in low airflow

and other system

effects.

1 Fan

Wheel

Dia.

1 Fan

Wheel

Dia.

Rota

tio

n

Rota

tio

n

R

ot

ation

R

ot

ation

Length of Straight Duct

GOOD

POOR

GOOD

POOR

GOOD

POOR

Turning

Vanes

Turning

Vanes

SYSTEM EFFECT FACTOR CURVES

FPM X 100

OUTLET VELOCITY

0 5 10 15 20 25 30 35 40 45

1.2

1.0

0.8

0.6

0.4

0.2

0.0

S

TA

TIC PRESSURE LOSS

CUR

VE

1

CUR

VE

2

CUR

VE

3

CUR

VE 4

Exhaust Weatherhood

The exhaust weatherhood is shipped

separately as a kit with its own

instructions.

Intermediate

Shipping Rail

(typical)