24

Model RT Energy Recovery Unit

Frost Control Application/Operation

Extremely cold outdoor air temperatures can cause

moisture condensation and frosting on the enthalpy

wheel. Frost control is an optional feature that will

prevent/control wheel frosting. Three options are

available:

1. Timed Exhaust frost control

2. Electric preheat frost control

3. Modulating wheel frost control

All of these options are provided with a thermostat

(with probe) mounted in the outdoor air intake

compartment and a pressure sensor to monitor

pressure drop across the enthalpy wheel. The typical

temperature setting corresponds to the indoor air

relative humidity as shown in the Frost Threshold

Temperatures

Table and

represents when

frost can occur.

An increase

in pressure

drop would

indicate that

frost is occurring. Both the pressure sensor and the

outdoor air temperature sensor must trigger in order

to initiate frost control. The two sensors together

ensure that frost control is only initiated during a

real frost condition. Field wiring of a light (or other

alarm) between 6 & C in the control center will notify

personnel when unit is in frost control mode (refer to

Remote Panel Wiring schematics section for wiring

details). The following explains the three options in

more detail.

Timed exhaust frost control

includes a timer

in addition to the thermostat and wheel pressure

sensor. When timed exhaust frost control is initiated,

the timer will turn the supply blower on and off to

allow the warm exhaust air to defrost the enthalpy

wheel. Default factory settings are 5 minutes off and

30 minutes on. Use the following test procedure for

troubleshooting.

Testing

(refer to Timer

diagram)

• Jumper the wheel

pressure switch

in the unit control

center. Set the

Timer Scale for T1

and T2 to 1 minute.

Set the Timer

Settings for T1

and T2 to 1.0. Set

the dip switch to

the down position.

(normal position)

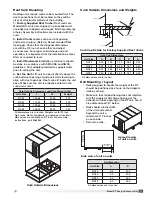

Frost Threshold Temperatures

Indoor RH

at 70°F

Frost Threshold

Temperature

20%

-10º F

30%

-5º F

40%

0º F

A1

B1

15

16

18

A2

0.2

0

0.4

1.0

0.6

0.8

0.2

0

0.4

1.0

0.6

0.8

T1

T2

T2

1 MIN

T1

1 MIN

Timer

Scale

Dip

Switch

Timer

• Turn the temperature sensor up as high as

possible. The supply blower should cycle on for

one minute, then turn off for one minute.

• After testing, set the

Timer Scale

as follows:

T1 = 10 minutes, T2 = 1 hour

• Set the

Timer Settings

as follows:

T1 = 0.5, T2 = 0.5. The timer is now set for 5

minutes off and 30 minutes on.

Remember to

remove the jumper.

Electric preheat frost control

includes an electric

heater (at outdoor air intake) and an airflow pressure

switch (located at the preheater) in addition to the

thermostat and pressure sensor on wheel. (Refer

to Electric Heater Application/Operation for electric

preheater location). When electric preheat frost

control is initiated, the electric preheater will turn

on and warm the air entering the energy wheel to

avoid frosting. Use the following test procedure for

troubleshooting.

Testing

• Turn the thermostat as high as it will go and

jumper the wheel pressure sensor. The heater

should turn on.

• If it doesn’t, either put the outdoor airside doors

on or temporarily jumper the airflow pressure

switch in the preheater control center to avoid

nuisance tripping of the pressure switch. Also

check the airflow switch pressure tap located

at the supply discharge blower to ensure the

tubing is connected and the tap is not blocked.

Remember to remove the jumpers.

Modulating wheel frost control

includes a variable

frequency drive in addition to the thermostat and

pressure sensor. When modulating wheel frost control

is initiated, the variable frequency drive will reduce

the speed of the wheel. Reducing the speed of the

energy wheel reduces its effectiveness, which keeps

the exhaust air condition from reaching saturation,

thus, eliminating condensation and frosting. If the

outdoor air temperature is greater than the frost

threshold temperature OR the pressure differential

is less than the set point, the wheel will run at full

speed. If the outdoor air temperature is less than

the frost threshold temperature AND the pressure

differential is greater than the set point, the wheel will

run at reduced speed until the pressure differential

falls below the set point. The temperature and

pressure differential set points are set at the factory,

but are field-adjustable (refer to VFD section for more

information). The variable frequency drive will be fully

programmed at the factory.