English - 5

Press both releasebuttons and the belt clip 5 will

automatically spring out. To remove the belt

clip 5 remove the complete fixture by unscrewing

the fastening screw.

By fixing the belt clip 5 make sure that the fasten-

ing screw is fully tighten.

The torque depends on the impact duration. The

maximum achieved torque results from all indi-

vidually achieved torques. The maximum torque

is achieved after an impact duration of 6 to

10 seconds. After this duration, the tightening

torque is increased only minimally.

The impact duration is to be determined for each

required tightening torque. The actually achieved

tightening torque is always to be checked with a

torque wrench.

Screw Applications with Hard,

Spring-loaded or Soft Seat

When in a test, the achieved torques in an impact

series are measured and transferred into a dia-

gram, the result is the curve of a torque charac-

teristic. The height of the curve corresponds with

the maximum reachable torque, and the steep-

ness indicates the duration in which this is

achieved.

A torque gradient depends on the following

factors:

– Strength properties of the bolts /nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being

screwed/bolted together

– Lubrication conditions at the screw /bolt con-

nection

The following application cases result accord-

ingly:

A hard seat is given for metal to metal screw ap-

plications with the use of washers. After a rela-

tively short impact duration, the maximum torque

is reached (steep characteristic curve). Unneces-

sary long impact duration only causes damage to

the machine.

A spring-loaded seat is given for metal to metal

screw applications, however with the use of

spring washers, disc springs, studs or bolts /nuts

with conical seat as well as when using exten-

sions.

A soft seat is given for screw applications, e. g.,

metal on wood or when using lead washers or fi-

bre washers as backing.

For a spring-loaded seat as well as for a soft seat,

the maximum tightening torque is lower than for a

hard seat. Also, a clearly longer impact duration

is required.

Calculated from the tensional cross-section; utilization of the yield point 90 %

(with friction coefficient µ

total

= 0.12)

☞

As a control measure, always check the tightening torque with a torque wrench.

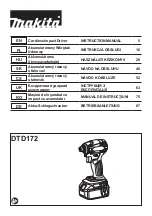

Operating Instructions

Reference Values for Maximum Bolt Tightening Torques in Nm

Property Classes

according to DIN 267

Standard Bolts

High-strength

Bolts

new 3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

until now 4 A

4 D

5 D

4 S

6 D

5 S

6 S

6 G

8 G

10 K 12 K

M 6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M 8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M 10

13

17.5

22

23

26

29

35

39

47

65

78

M 12

22.6

30

37.6

40

45

50

60

67

80

113

135

M 14

36

48

60

65

72

79

95

107

130

180

215

2 609 140 255.book Seite 5 Montag, 13. September 2004 9:55 09

17 • 2 609 140 255 • 04.09