18

Intended Use

This tool is intended for

t h e

t i g h t e n i n g

a n d

l o o s e n i n g o f b o l t s , n u t s a n d v a r i o u s

t h r e a d e d f a s t e n e r s .

T h i s t o o l i s n o t

intended for use as a drill.

Variable Speed Controlled

Trigger Switch

Your tool is equipped with a variable speed

trigger switch. The tool can be turned "ON"

or "OFF" by squeezing or releasing the

trigger. The speed can be adjusted from the

minimum to maximum nameplate RPM by

the pressure you apply to the trigger. Apply

more pressure to increase the speed and

release pressure to decrease speed (Fig. 1).

Brake

When the trigger switch is released it

a c t i v a t e s t h e b r a k e t o s t o p t h e c h u c k

quickly. This is especially useful in the

repetitive driving and removal of screws.

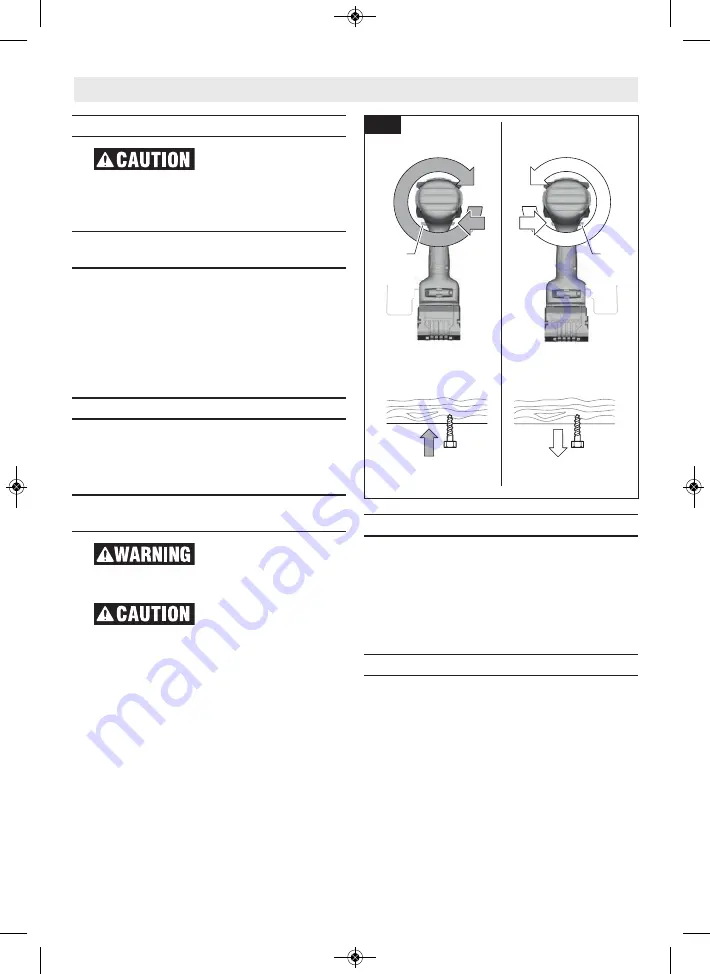

Forward/Reversing Lever

and Trigger Lock

A f t e r t o o l u s e , l o c k

t r i g g e r

i n

“ O F F ”

position to help prevent accidental starts

and accidental discharge.

Do not change direction

of rotation until the tool

comes to a complete stop.

Shifting during

rotation of the chuck can cause damage to

the tool.

Your tool is equipped with a forward/

reversing lever and trigger lock

(3)

located

above the trigger (Fig. 10). This lever was

d e s i g n e d f o r c h a n g i n g r o t a t i o n o f t h e

socket, and for locking the trigger in an

“OFF” position.

To lock the trigger, move the lever to the

center.

For forward rotation, (with chuck pointed

away from you) move the lever to the far

left.

For reverse rotation move the lever to the

far right. To activate trigger lock move lever

to the center off position.

Built-in work light

Your tool is equipped with an LED light

(13)

for better visibility when using the

tool.

After the trigger

(8)

is activated, the LED

will then stay on for 10 seconds. The length

of time for afterglow can be changed in

‘Bosch ToolBox’ app setting (if connected).

Operating tips

You will extend the life of your bits and do

neater work if you always put the bit in

contact with the work before pulling the

trigger. During the oper a tion, hold the tool

firmly and exert light, steady pressure. Too

much pressure at low speed will stall the

tool. This can be damaging to both tool

and bit.

Driving with variable speed

The technique is to start slowly, increasing

the speed as the screw runs down. Set the

screw snug ly by slowing to a stop. Prior to

driving screws, pilot and clearance holes

should be drilled.

Operating Instructions

(3)

(3)

Fig. 10

2610067376 08-21 GDS18V-740C.qxp_GDS18V-770 8/18/21 7:00 AM Page 18