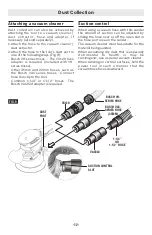

Microfilter Dust Canister

The integral dust extraction system collects

sanding dust in canister supplied with your

sander. For maximum efficiency, the dust

c a n i s t e r s h o u l d b e e m p t i e d f r e q u e n t l y

during operation.

Y o u r t o o l i s e q u i p p e d

w i t h a d u s t c a n i s t e r ;

empty it frequently after completion of

sanding and before storing the sander.

Be

extremely careful of dust disposal, materials

in fine particle form may be explosive. Do

not throw sanding dust on an open fire.

Combustion from mixture of varnishes,

lacquers, polyurethane, oil or water with

dust particles can occur if there is a static

discharge, spark introduced in the box, or

excessive heat.

Dust Collection

2

1

FIG. 5

DUST

CANISTER

-10-

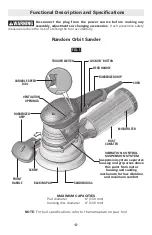

Backing Pad Damper

Your tool is equipped with an integrated

backing pad damper ring. This damper

reduces the no-load speed, which helps

p r e v e n t s w i r l m a r k s o n t h e w o r k p i e c e

surface and provides uniform finishing.

NOTE:

If you notice steadily increasing no-

load speed, this indicates that the damper

ring is worn and needs to be replaced.

To replace damper ring, remove backing

p a d a s d e s c r i b e d i n “ B a c k i n g P a d

Installation” and remove worn damper ring

by pulling firmly out of locating groove.

Align notch on damper ring with locating

t a b o n s h r o u d a n d d e p r e s s r i n g w i t h

t h u m b s u n t i l s h r o u d s e a t s i n t o g r o o v e

completely around ring (Fig. 4).

R e - a t t a c h b a c k i n g p a d a s d e s c r i b e d i n

“Backing Pad Installation”.

IMPORTANT:

Ring should not have bends or

ripples when correctly seated.

Assembly

DAMPER

RING

SHROUD

BACKING

PAD

LOCATING

TAB

FIG. 4

NOTCH