18

| English

1 609 92A 4LE | (17.10.2018)

Bosch Power Tools

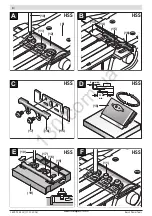

Fitting the Planer Blades (see figures I–J)

The guide groove on the planer blade ensures a constant,

even height setting when changing or turning the blade.

If necessary, clean the blade seat in the blade head

(13)

and

the planer blade

(20)

.

When fitting the planer blade, ensure that it is correctly

seated in the mounting guide of the blade head

(13)

.

The planer blade must be fitted and aligned with the

centre

of the planer base plate

(8)

. Then tighten the three fasten-

ing screws

(11)

using the Torx key

(10)

, following the tight-

ening sequence (

①②③

) specified on the clamping jaw

(12)

.

Note:

Check that the fastening screws

(11)

are firmly

tightened before start-up. Turn the blade head

(13)

by hand

and ensure that the planer blades are not brushing against

anything.

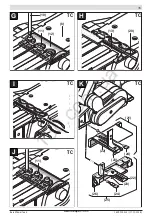

Use of conversion kits

Changing from HSS to HM/TC

The HM/TC adapter enables a planer fitted with HSS planer

blades to be changed over to HM/TC planer blades.

– Unscrew the three fastening screws

(11)

using the Torx

key

(10)

and remove the clamping jaw

(12)

.

– Push the retaining clip

(16)

together with the planer

blade

(15)

out of the blade head

(13)

and/or the guide

groove

(14)

.

– Remove the screws

(17)

.

– Place the retaining clip

(16)

and the adapter

(34)

in the

setting gauge

(19)

. The retaining clip

(16)

must slot into

the groove on the setting gauge (see figure

R

).

– Push the HM/TC planer blade

(20)

into the adapter

(34)

from the side. The ridge on the adapter

(34)

must slot

into the groove on the HM/TC planer blade (see figure

R

).

– Tighten the screws

(17)

.

– Insert the retaining clip

(16)

together with the adapter

(34)

and the planer blade

(15)

into the blade head

(13)

and/or the guide groove

(14)

.

– Put the clamping jaw

(12)

on and insert the fastening

screws

(11)

, which do not yet need to be screwed in

tightly.

– The planer blade must be fitted and aligned with the

centre of the planer base plate

(8)

. Then tighten the

three fastening screws

(11)

using the Torx key

(10)

, fol-

lowing the tightening sequence (

①②③

) specified on

the clamping jaw

(12)

.

Changing from HM/TC to HSS

Planers fitted with HM/TC planer blades can be changed

over to HSS planer blades.

– Unscrew the three fastening screws

(11)

using the Torx

key

(10)

and remove the clamping jaw

(12)

.

– Push the retaining clip

(16)

together with the planer

blade

(15)

and/or the HM/TC adapter

(34)

out of the

blade head

(13)

.

– Remove the screws

(17)

.

– Fit the assembled HSS planer blade (see "Fitting the

with the

centre of the planer base plate

(8)

.

– Put the clamping jaw

(12)

on and tighten the three

fastening screws

(11)

using the Torx key

(10)

, following

the tightening sequence (

①②③

) specified on the

clamping jaw

(12)

.

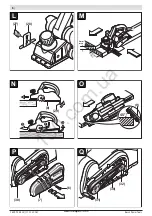

Dust/chip extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reac-

tions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials contain-

ing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u

Avoid dust accumulation at the workplace.

Dust can

easily ignite.

Clean the chip ejector

(3)

regularly. Clean a clogged chip

ejector using a suitable tool, e.g. a piece of wood, com-

pressed air, etc.

u

Do not allow the chip ejector to come into contact with

your hands.

You may be injured by rotating parts.

Always use an external dust extraction device or chip/dust

bag to guarantee optimum suction.

Operation

Operating modes

Setting the Cutting Depth

Using the knob

(2)

, the cutting depth can be continuously

adjusted between 0–2.6 mm with the aid of the cutting

depth scale

(1)

(scale division = 0.1 mm).

Parking Rest (see figure N)

The parking rest

(29)

makes it possible to put down the

power tool directly after working, without any danger of

damaging the workpiece or the planer blades. During the

work process, the parking rest

(29)

is raised and the rear

section of the planer base plate

(8)

is uncovered.

Start-up

u

Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230 V can also be operated with 220 V.

Автотовари

«130»

130.com.ua