-13-

Operating Instructions

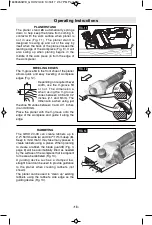

PLANER STAND

The planer stand

26

automatically springs

down to help keep the blade from coming in

contact with the work surface when planer is

not in use (Fig. 11). The planer stand is

designed to swing up and out of the way by

itself when the back of the plane crosses the

leading edge of the workpiece (Fig. 9). It will

also swing up when planing begins in the

middle of the work piece (in from the edge of

the work piece).

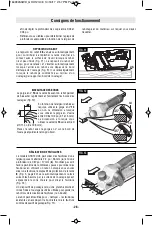

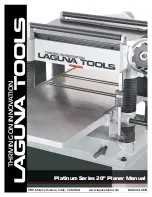

RABBETING

The GHO12V-08 can create rabbets up to

2.2"/ 56mm wide (

a

) and 0.67"/17mm deep (

b

).

Keep in mind that it may take many passes to

create rabbets using a planer. When planning

to create a rabbet, the blade guard

8

(Fig. 3,

page 8) will be automatically lifted as needed

by the surface of the workpiece that is adjacent

to the area be rabbeted (Fig. 13).

A guiding device such as a clamped low,

straight board can be used to provide guidance

to the planer when creating rabbets (not

shown).

The planer can be used to “clean up” existing

rabbets using the rabbet’s side edge as the

guiding device (Fig. 13).

a

b

FIG. 13

26

FIG. 11

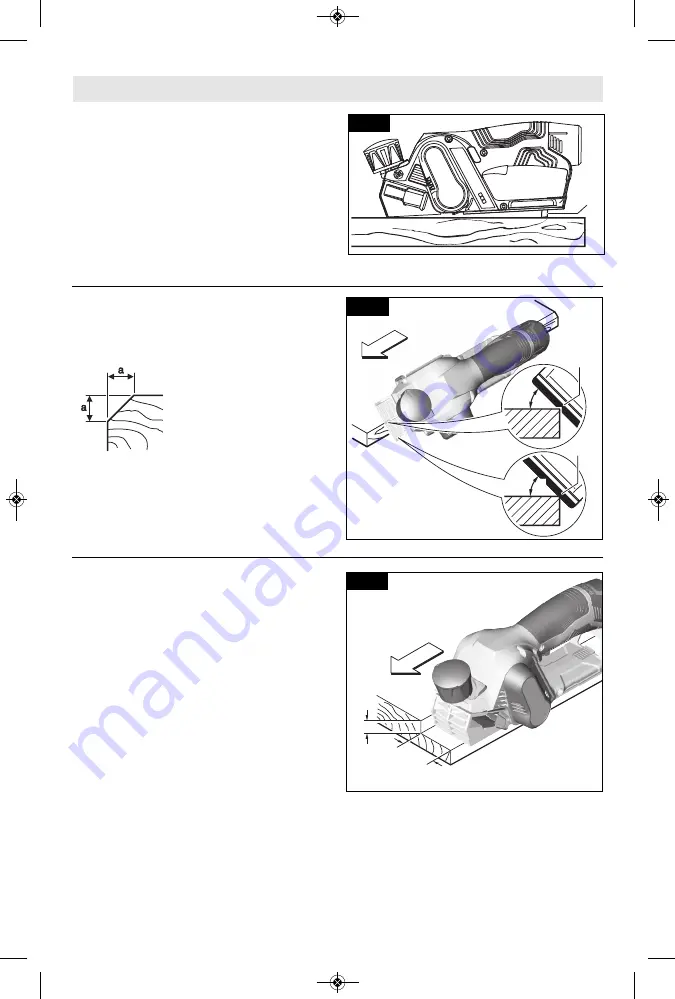

BEVELING EDGES

The V-groove

14

in the front shoe of the planer

allows quick and easy beveling of workpiece

edges (Fig. 12).

Depending on required bevel

width, use the V-groove

14

or not. The dimension a

when using the V-groove

varies between 0.08 and 0.2

inches (2.1 and 5mm). The

dimension a when using just

the shoe

13

varies between 0 and 0.11 inches

(0 and 2.8mm).

Place the planer with the V-groove onto the

edge of the workpiece and guide it along the

edge.

45°

45°

14

13

FIG. 12

160992A3WD_GHO12V-08 10/16/17 2:57 PM Page 13